Course:FNH200/Projects/2021/Nongshim - Shin Ramyun

Introduction

Originally developed by Momofuku Ando in Japan, the intention was to eradicate world hunger through instant noodles, of which the invention became an instant popular sensation. To this date, instant noodles are one of the most widely selected options for a quick meal on the go, and to some extend serving as a household food staple. The consumption of instant noodles has since spread throughout the world with a steady increase. Given the countless variety offerings and different flavors to choose from, concerns regarding the health implication of certain chemicals used in the food remain a widely debated topic. As a team, we have chosen a particular Korean instant noodle brand for our research, the "Nongshim Shin Ramyun" instant noodles, known for their soft and chewy texture along with the bold and spicy flavors. Our main objective in this research is to investigate how instant noodles are manufactured, as well as what methods and ingredients are utilized in the process. Through this, the Wiki page is categorized into three main components, starting from the noodles themselves, to the seasoning involve, and eventually, concluding on the exploration of health concerns and government regulations.

The Noodle Component

Ingredients Used

The noodle component of the Nongshim Shin Ramyun contains wheat flour, potato and wheat starches, vegetables oil (containing antioxidants (307B)), salt, mineral salts (501, 500, 452, 339), soy sauce, green tea extract and emulsifiers, such as soy[1].

Antioxidants

In this brand of instant noodles, antioxidant 307B is used in order to prevent oxidation between the fat and oil content[2]. Antioxidant 307B is a extracted from vegetable oils (generally sunflower oil)[3]. They are enriched with tocopherols (vitamin E) and are characterized by their reddish clear colour and show slight separation of wax-like ingredients when in microcrystalline form. Tocopherols are the preservative agents that delay food spoilage in Nongshim Shin Ramyun[4].

Soy Emulsifiers

Emulsifiers interact with starches to create good quality dough and increase the rate of water absorption by 1-2%. By integrating emulsifiers, the noodle dough becomes uniform, smooth and easy to handle, ultimately, improving the production process. Thus, the brand utilizes soy to improve absorption and decrease cooking time[5].

Mineral Salts - Sodium Carbonate, Potassium Carbonate, Polyphosphates, Sodium Phosphate

Shin Ramyun's concoction of mineral salts in its noodles serves a wide range of purposes, with each mineral salt providing its own value to the noodle. Certain ingredients incorporated into the Shin Ramyun Noodles also give rise to the colour and unique, chewy, texture of the instant noodles. The historic usage of ‘salt water’ and high alkaline solutions was proven to provide the yellow and chewy texture of noodles.

Strong alkaline solutions, such as sodium carbonate (mineral salt 500), when mixed with fats from vegetables or animals, generates a reaction called saponification. This chemical reaction is the basis for the ‘soapy’ texture of noodles, resulting in a chewy and slippery consistency[6]. Because of this 'soapy' texture and, its corrosivity and volatility, it is known as 'washing soda'. Fortunately, it is still safe to use in small quantities while cooking[7]. Sodium carbonate also acts as a leavening agent to help the dough expand and rise, giving the noodle its porous structure[8].

Potassium carbonate (mineral salt 501), more commonly known as baking soda, is further used to enhance the texture and colour of the Shin Ramyun noodles. When dissolved in water, potassium carbonate forms a strong alkaline solution. It is divided into two main groups, heavy and light; light potassium carbonate is used in fields of food such baked goods, wine, and ramen noodles. It interacts with protein, hardening the texture of the dough, creating an elastic characteristic to the noodles, and changing its colour by producing a deeper yellow[9]. Further, potassium carbonate adds an alkaline smell and is used to raise the pH of the dough, which shortens cooking time. Greater proportions of potassium carbonate is used with wheat flour to create thin, elastic noodles. However, when mixed with sodium carbonate, the noodle texture is balanced as it is used to soften and provide a chewy texture that is characteristic to ramen noodles[10].

Polyphosphate (mineral salt 452) is used in the baking powder of the noodle to further improve the eating quality and water retention, ensuring water is absorbed into the noodle when the consumer cooks it. When ingested, the polyphosphates break down to single phosphate units in the stomach, presenting minimal hazard to health when ingested in such small amounts[11].

When incorporated into the mix of ingredients, sodium phosphate (mineral salt 339) serves a number of uses that enhance the texture of the noodle. Most notably, it thickens the noodle and stabilizes the texture of the ramen, giving Shin Ramyun its characteristic chewiness and taste. Sodium phosphate also works in tandem with potassium carbonate and sodium carbonate as another leavening agent to help the noodle dough rise. Finally, the mineral salt balances pH levels, which is critical to extending the long shelf life of the noodle and further improving the taste[12].

Green Tea Extract

The use of green tea extract in processed ramen noodles improves the strength of the noodle dough and promotes the process of starch gelatinization[13]. During starch gelatinization, gas bubbles in the noodle dough expand and burst to form the porous structure of the dry ramen, which is essential to the noodle absorbing water during the cooking process for consumption[14]. Furthermore, green tea extract decreases the hardness of the noodle, but the additive does not reduce the noodle's cohesiveness and cooking yield, ensuring that its texture is improved without compromising its structural integrity[13].

Manufacturing and Processing

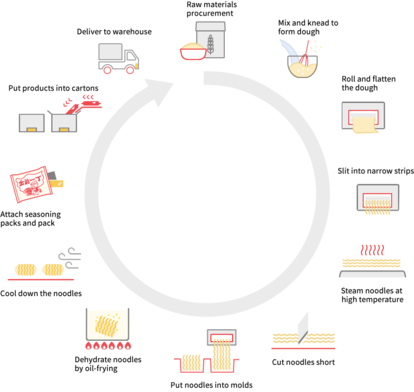

The noodles are manufactured and processed in a series of steps:

- A dough is mixed and kneaded using wheat flour, water and an alkaline solution.

- Using a compounding machine, the dough is pressed to form sheets and is left for some time to mature.

- Rollers continue to thin the dough.

- Then, a slitter with rotating blades cuts the dough into thin, wavey, noodle shapes. This specific shape helps prevent them from sticking.

- At approximately 100 degrees, the noodles are steamed for 1-5 minutes. This process forms highly-digestible pregelatinized starch.

- After steaming, the noodles are dipped in a bath of seasoning.

- The noodles are cut again to 40-70 cm in length in a feeder and shaped into square or circular serving molds.

- In a flash fryer, the metal molds are put into hot oil for 1-2 minutes. This further reduces the moisture content to 3-6%.

- The dehydrated noodles are then air cooled and checked for quality.’

- Each serving is weighed and checked for metal material. The servings that fail the quality check do not proceed to distribution and are discarded.

- The dehydrated noodles are hermetically packed into film-lined, aluminum packages with sachets of garnishes and seasoning.

- Each package is weighed again. Any packages with incorrect weights are discarded

- The final packages are put into cardboard cases for distribution[2].

Preservation

When regarding preservation - dehydration and high temperature treatments are used by Nongshim Shin Ramyun. The original Shin Ramyun is preserved through deep fat frying. This high temperature treatment causes the water in the food to quickly evaporate which lowers the water content and water activity. Preservation of noodles are maintained by ensuring low water activity, by using specific packaging, and bacteriostatic effect by pH control. However, when using the deep fat frying method, it adds a high oil content to the noodles and that greatly increases the amount of available calories[16].

Nongshim did develop a Shin Ramyun Dried Noodle which is not deep fat fried and is hot air dried instead. This allows the caloric intake to be lowered to 350 kilocalories which is about 30% lower than conventional instant noodles[17].

Packaging

The dehydrated noodles proceed to be packaged. Because a lower water activity needs to be maintained to ensure dehydration and preservation, this brand of instant noodles utilizes aluminum bags for packaging. Due to low water activity levels caused by dehydration, they are considered hygroscopic - readily able to pick up moisture. So, the packaging must ensure there is no transmission of water vapour entering the food from the environment. There should also be protection from oxygen and light. The noodle packages are then distributed in cardboard boxes for physical protection. To further improve preservability, the durable packaging materials also block humidity, heat, and oil[2].

For prolonged storage and prevention of quality deterioration, the World Instant Noodles Association (WINA) recommends following certain procedures, such as:

- Keeping the packages out of direct sunlight

- Storing them at ambient temperatures

- Place in areas where there is no humidity

- Keep away from odorous substances[2]

The Seasoning Component

The Seasoning Powder

In addition to the soft, chewy noodles, the bold, flavourful, spicy broth seasoning is what made Shin Ramyun become an instant hit among consumers globally. The seasoning packet contains salt, black pepper, garlic, red chili pepper, wheat gluten, soy sauce, yeast extract, sugar, fructose, soybean, wheat flour, vegetable oils, onion extract, green onion and kelp extract, mushroom extract, radish extract, corn starch, yellow corn flour, glucose, dextrose, hydrolyzed soy protein, maltodextrin, disodium succinate, disodium guanylate, disodium inosinate, gum arabic, and lecithin[1]. In this long list of ingredients, our team identified a few components that act as flavour enhancers, thickening agents, emulsifiers, or sweeteners, which gives the seasoning powder its necessary and unique flavour.

Flavour enhancers:

It is noticed that monosodium glutamate (MSG) is absent from the list of ingredients in the seasoning, as the Nongshim company claimed that MSG is not used in any of its products manufactured in Korea. This raises the question of which ingredients enhance the flavouring of the soup base[18].

Disodium succinate is added as a flavor enhancer that improves the seafood and umami tastes of the food product when combined with other flavor enhancers, such as disodium ribotides and hydrolyzed vegetable proteins that are present in the seasoning powder[19]. Disodium ribotides, also known as disodium 5’-ribonucleotides and I + G, are the combination of guanylate and disodium inosinate, and they serve as a flavor enhancer in creating the umami taste on the palette[20]. They are produced by synthesizing the sodium salts of the natural compounds of guanylic acid and inosinic acid, and they may be used as an MSG replacement[20][21].

Hydrolyzed soy protein is a protein hydrolysate that provides a source of vegetable proteins and naturally enhances the umami flavouring of the soup base. They are made by the following four steps: hydrolysis, neutralization, filtration, and ripening, where the soy proteins are enzymatically broken down into shorter amino acid chains or free amino acids by proteases[22]. Although MSG is not explicitly listed on the ingredients, hydrolyzed soy protein actually contains naturally occurring glutamic acid, and generally has 10 to 30% MSG[23]. In other words, the hydrolyzed proteins, which includes free glutamate, will form MSG once it comes in contact with the salts present in the food product[24]. Similarly, the yeast extract also acts as a flavour enhancer by imparting umami taste and contains naturally occurring glutamates[25].

In Canada, claims that pertain to the absence of MSG are prohibited and considered to be misleading when food products involve ingredients that contain free glutamates, such as hydrolyzed soy proteins and yeast extracts[26]. However, Canada does not provide any labeling requirements for food products that do have natural, free glutamates[26].

Other vegetable extracts in the seasoning ingredients, such as onion, green onion, kelp, mushroom, and radish extracts, are added as flavour enhancers as well, giving the soup base a thick, rich aroma and taste[27].

Sweetening agents, thickening agents, and emulsifiers:

Maltodextrin is a common ingredient found in several processed foods and they are generally added as a thickening agent or a sweetening agent. It is a white powder made from rice, corn, potato starch, or wheat. Along with maltodextrin, dextrose, fructose, glucose, and sugar are also used as sweetening agents in the seasoning powder[28].

Gum arabic is added as a natural thickening agent and emulsifier, available in an aqueous solution or dry powder form[29]. Moreover, soy lecithin is also found in the seasoning powder as it is a common and naturally occurring emulsifier that helps maintain a stable emulsion within the soup base[30].

Other ingredients:

Apart from the flavour enhancers, sweetening agents, thickening agents, and emulsifiers, the basic seasonings, such as salt, black pepper, and red chili pepper, listed in the ingredients play an integral role in giving Shin Ramyun’s flavourful taste.

Packaging

The packaging process of the seasoning powder typically occurs in the following steps:

- Pre-treatment: Liquid and paste-like ingredients, such as vegetable extracts, are dehydrated along with salt and crushed into a powder form.

- Pre-mixing: The raw materials, including spices and amino acids, are pre-mixed apart from the pre-treated ingredients.

- Mixing: The pre-treated and pre-mixed ingredients are combined with other raw materials. During mixing, the temperature and humidity of the environment are maintained constant to ensure that the seasoning remains dry for the next steps.

- Inspection: Inspection is conducted for quality control.

- Subdivided packing: The final product of the powdered seasoning is packaged into sachets by an automated filling instrument[2].

The seasoning powder of the Shin Ramyun has undergone mixing and dehydration processes, and is packaged into aluminum sachets. This packaging method aims to preserve the quality of the soup base and maintain the dehydrated state by preventing moisture, oxygen, and light exposure to the product.

The Dried Flakes

The ingredients listed for the manufacturing of the flakes present in the seasoning are: dried vegetables, soybean, soy sauce, wheat gluten, yeast extract, sugar, salt, cocoa, corn starch, and vegetable oil (soy).[1] The vegetables are dried via freeze drying, a method of dehydration. By the process of sublimation, water is removed from the vegetables while in the frozen state without transitioning through the liquid phase. This occurs in freezing, vacuum conditions. Then, the vegetables are passed through radiant heaters, drying them.[31] The cooking time for the Nongshim Instant Noodles is 4-5 minutes, as suggested on the packaging. Therefore, the method of dehydration for the dried flakes must be freeze drying. The presence of salt and sugar further lowers the water activity levels in the dried flakes to maintain the dehydrated state of the dried vegetables. The usage of yeast extract enhances the umami taste, bringing a meaty note in the noodles and creating a delicious aftertaste.

Packaging

Instant noodle garnishes are typically dehydrated using one of the following methods:

- Hot air: dehydrates fresh garnishes, such as vegetables.

- Vacuum freeze drying: Garnishes are rapidly frozen. This prevents loss of nutritional value and assists in easy rehydration. This is often used for protein-rich materials.

- Microwave heating drying: Often used for eggs, this method gives the garnishes internal heat, thus achieving tissue formation and dehydration.

- Retort: Food is filled in pouches, followed by sterilization by heat and pressure[2].

The dried flakes in the Shin Ramyun noodles are dehydrated via hot air. After dehydration, the dried garnishes are packaged into plastic packets. This material of packaging prevents air oxygen and light from entering, therefore, maintaining the dehydration and low water activity levels of the garnishes.

Health Concerns and Government Regulations

High Sodium Content

Sodium is utilized in processed foods to enhance flavour and extend shelf life. Because the noodles are dehydrated via deep fat frying, a low water activity needs to be maintained. So, salts employ preservative effects by binding to free water, therefore, lowering water activity. Further, at high concentrations, like in the Nongshim Ramyun Noodles, sodium also has a dehydrating effect on the microbial cells of the food product.[32]

In addition, sodium enhances the flavour of the seasonings present in the packaging contents. Seasonings, such as soy sauce powder, contain high concentrations of sodium. Unlike other popular instant noodle brands, Nongshim Ramyun Noodles do not use MSG (monosodium glutamate) in their ingredients.[33] The brand, instead, uses higher levels of salt-derived ingredients such as disodium guanylate, disodium inosinate, and disodium succinate.

Thus, the high sodium content in the package of instant noodles is used to enhance the flavouring of the seasoning provided in the package of noodles, while extending its shelf life through the promotion and maintenance of lowered water activity and dehydration.

Health Concerns and Canadian Government Regulations

The Nutritional Facts table located on the back of the Nongshim Ramyun Noodles displays 880 milligrams of sodium per 60 grams. This tabulates to 1760 milligrams of sodium per package. According to Health Canada, teenagers (ages 9-13) and adults (14-50) should consume 1500 milligrams per day. Excessive consumption of sodium leads to negative impacts on kidney and heart health, including heart disease and stroke, increased blood pressure, and higher risk of stomach cancer.[34]

The question, then, arises of regulation of imported foods amid various health concerns. Inspections Canada’s Safe Food for Canadians Regulations (SFCR) is a handbook which ensures that imported food is safe for consumption. Division 5 of the SFCR requires immediate CFIA notification when a risk to human health has been recognized. Foods may also be prevented from entering the retail market if they are proven contaminated. However, the SFCR is also situated with internationally recognized standards, such as Codex Alimentarius.[35] This ensures food safety and consumer protection requirements with internationally imported food products. Therefore, Nongshim Ramyun Noodles must have aligned with internationally recognized regulations to be permitted entry to Canada.

Exam Question

Question: Emulsifiers, such as soy, interact with starches in instant noodles to improve ____ and decrease _____?

Choices:

- Absorption; cooking time

- Flavour; absorption

- Texture; oxidation

- Consistency; pH

Correct Answer: (1) Absorption; cooking time.

Explanation: Emulsifiers, in instant noodles, interact with starches to increase the rate of water absorption by 1-2%. Also, by producing good quality dough via the usage of emulsifiers, the required cooking time for the noodles decreases.

With the increasing popularity of instant noodles, it is important to know what processing method and ingredients are added to make this "instant" food time-saving and delicious. The chemical properties play a major role, as in the case with emulsifiers, it helps to spread fat and oil evenly across and stabilize the quality of the product. Thus, enabling the surface of the noodles to become smooth, uniform and less sticky, significantly impacting the subsequent firmness, springiness, and overall consumer acceptability in the instant noodles.

Resources:

- ↑ 1.0 1.1 1.2 "The Authentic Spicy Noodles". Shin Ramyun Noodles. Retrieved August 8, 2021.

- ↑ 2.0 2.1 2.2 2.3 2.4 2.5 "FAQs". World Instant Noodles Association. Retrieved August 9, 2021.

- ↑ Culinary Communications P Limited. "Antioxidant (INS 307b)". gotoChef. Retrieved August 11, 2021.

- ↑ Noshly. "Wise eating, made easy". Retrieved August 11, 2021.

- ↑ "Food Emulsifier Application". Riken Vitamin. 2018. Retrieved August 9, 2021.

- ↑ "What Sodium Carbonate Can Do For You..." Zesty and Spicy. June 18, 2017. Retrieved August 9, 2021.

|first=missing|last=(help) - ↑ Ariel. (June 18, 2017). "What Sodium Carbonate can do for you". Zesty and Spicy. Retrieved August 11, 2021.

- ↑ "Sodium Bicarbonate: A Multipurpose Ingredient For Food Applications". Asia Pacific Food Online. October 30, 2017. Retrieved August 11, 2021.

- ↑ Sperss, P. (April 19, 2019). "On Ramen noodles – A biochemist's take". La Petit Noisette. Retrieved August 11, 2021.

- ↑ Han, James (September 21, 2020). "What're the Uses of Potassium Carbonate E501(i) in Food and other Common Applications?". Food Additives. Retrieved August 9, 2021.

- ↑ Aitken, A. (1975). Polyphosphates in fish processing. Ministry of Agriculture, Fisheries and Food, Torry Research Station.

- ↑ Whelan, Corey (September 18, 2018). "Sodium Phosphate". Healthline. Retrieved August 11, 2021.

- ↑ 13.0 13.1 Xu, Min; Wu, Ying; Hou, Gary G.; Du, Xianfeng (November 20, 2018). "Evaluation of different tea extracts on dough, textural, and functional properties of dry Chinese white salted noodle" (PDF). LWT - Food Science and Technology. 101: 456–462 – via Elsevier Science Direct. line feed character in

|title=at position 72 (help) - ↑ "Starch Gelatinization". Bakerpedia. Retrieved August 11, 2021.

- ↑ farmsoft. "Instant Noodles Manufacturing Process".

- ↑ "Does instant Ramen expire? 7 burning questions ANSWERED". Apexsk. Retrieved August 11, 2021.

- ↑ Lee, Duk-joo; Kim, Hyo-jin (February 7, 2019). "Nongshim to launch non-fried Shin Ramyun noodle variant". Pulse by Maeil Business News Korea. Retrieved August 11, 2021.

- ↑ World of Shin (2020). "Products". Shin Ramyun.

- ↑ Food Additives (2020). "What Is Disodium Succinate In Food And Difference With Monosodium Succinate?". Food Additives.

- ↑ 20.0 20.1 Food Chem (2021). "Disodium 5′-Ribonucleotides(I+G)". Food Chem.

- ↑ NovoTaste (2020). "Disodium Guanylate: Uses, Nutrition, and Safety | Healthline". NovoTaste.

- ↑ Food Additives (2019). "What is Hydrolyzed Soy Protein or HVP: Uses, Safety and Side Effects". Food Additives.

- ↑ Scopp, A L (1991). "MSG and hydrolyzed vegetable protein induced headache: review and case studies". PubMed.gov.

- ↑ Yacoubou, Jeanne (2011). "MSG, Hydrolyzed Proteins, and Autolyzed Yeast Extracts: Classified as Flavor Enhancers, not Natural Flavors". The Vegetarian Resource Group Blog.

- ↑ Guo, Chris (N/A). "Taste Preference of Instant Noodles in the Asia Pacific and its Application to Yeast Extract". Angel Yeast. Check date values in:

|date=(help) - ↑ 26.0 26.1 Government of Canada (2008). "Monosodium glutamate (MSG) - Questions and Answers". Government of Canada.

- ↑ World Food Innovations (N/A). "Vegetable Extracts Enhancing Flavor, Reducing Sodium". World Food Innovations. Check date values in:

|date=(help) - ↑ Diabetes Canada (2018). "Sugars and Sweeteners" (PDF). Diabetes Canada.

- ↑ Food Additives (2019). "What is Gum Arabic (E414) in food: Sources, Uses, Health benefits, Substitutes". Food Additives.

- ↑ Kouassi, Marielle (2020). "'Why is Lecithin in my Food?' An Overview of Emulsifiers". Kerry Health and Nutrition Institute.

- ↑ Chan, Judy (June 24, 2020). "Lesson 08- Dehydration as a Food Preservation Method". UBC Wiki. Retrieved August 8, 2021.

- ↑ Chan, Judy. "Lesson 5: Rational for Food Preservation". UBC Wiki. Retrieved August 6, 2021.

- ↑ "Explore Our Product". World of Shin. 2020. Retrieved August 6, 2021.

- ↑ "Sodium in Canada". Health Canada. March 1, 2017. Retrieved August 6, 2021.

- ↑ "Understanding the Safe Food for Canadians Regulations: a handbook for food businesses". Inspections Canada. October 30, 2020. Retrieved August 6, 2021.