Course:FNH200/Projects/2021/Brie Cheese

Introduction

Brie (/brē/) is a creamy, smooth and soft cheese made from cow's milk with its notorious white rind made of mold. It typically comes in the shape of a round and thick pancake. Brie was first seen during the medieval period in Europe, later becoming popular in Paris during the 14th century as it was proudly served to the Kings of France [1]. Brie de Meaux is known to be the finest type of Brie made. As of now, Brie is a widely known cheese to eat accompanied with crackers, fruits and nuts. The process of making Brie requires multiple stages in order to be properly made and sanitary to eat. Stages include: milk ripening, coagulation and molding, and finally, salting, drying and ripening. As a result, you get a cheese made with the help of Penicillium Camemberti.

How is Brie Made?

Stages

Stage 1: Milk Ripening

Rennet is added to pasteurized or unpasteurized raw cow milk [2]. The milk is never heated past a lukewarm temperature [3], but only to 7-15°C for 13-18 hours, causing the pH to drop by 0.5 [2].

Stage 2: Coagulation and Molding

Temperature is increased to 34°C for 5 hours, increasing lactic bacteria growth and lactic acid production, which will cause a drop in pH of about 2 [2]. The cheese is put into circular hoop molds where it is drained without pressing [3]. The cheese is left to be drained for about 15 hours at 34°C [2].

Stage 3: Salting, Drying, Ripening

A mold fungus, Penicillium camemberti, is added to the cheese [2] which eventually causes a white outer crust to form [3]. The cheese is dried in a drying room for 24 hours at 18°C [2]. Enzymes that are produced by P. camemberti break down proteins in the inside of the cheese, creating the soft, creamy texture that Brie cheese is known for [3]. The cheese is allowed to ripen at 9.5°C for 12 days, and then reduced to 7°C for around 49 days [2]. The cheese is ready when the most center part of the cheese goes from a chalky center into a soft creamy texture, demonstrating that the enzymes have broken up all the protein throughout the cheese [3]. Once the cheese is transferred to a market, the cheese is labelled with a maximum “best before date” of 35 days but is often consumed earlier [2].

What bacteria is used to produce brie?

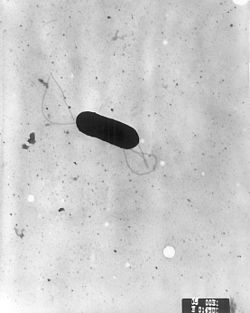

Penicillium camemberti is the bacteria used in the production of Brie cheese. Colonies of the fungus form a hard white outer crust - characteristic of the appearance of these surface-ripened soft cheeses [4]. P. camemberti is a salt tolerant fungus, and in addition to its ability to grow at water activity of 0.93, results in the fungus growing on the surface of the Brie during the cheese maturation process[4]. It is also strictly aerobic, thus, it will only grow on the cheese surface[5]. P. camemberti starter cultures are also responsible for inhibiting undesirable growth of common fungal contaminants of cheese; like Cladosporium hebarum and P. roqueforti, as well as for giving Brie its distinctive flavour[4]. Additionally, during the ripening process of Brie, P. camemberti metabolizes lactate to CO2 and H2O at the surface, establishing a pH gradient - a key factor in the maturation process that results in a higher pH[4].

Packaging and Shelf Life

Packaging for brie is complicated and plays a significant role in determining the shelf-life and ripening of the cheese. The permeability of the package for gas exchange and moisture is crucial as the surface mould on the cheese needs to stay alive for proper ripening[6]. The structure of the cheese can collapse in the package if not handled carefully which is another complication with packaging soft cheeses such as brie.

Most similar cheeses are packaged commercially with an inner layer of wax, paper, then finally an outer varnish layer. This shortens the shelf life as it leads to a low O2 concentration[7].

There are various methods suggested for these cheeses such as the Monte Carlo technique and MAP (Modified Atmosphere Packaging).

MAP are used to extend shelf life of the cheeses[7] through controlling the ripening rate[6]. MAP in this case is used to control the O2 and CO2 exchange rates and penetration ability of the packaging.

Safety of Brie Cheese

What makes the mold on brie safe to eat compared to mold on other foods?

Consumable molds in cheese differs from molds that generally cause food spoilage; most molds that appear on foods generally indicate a sign of spoilage, but there are also many safe culinary applications of mold. Specifically in brie cheese, the mold is used for a multitude of purposes, such as adding to the distinct flavour[8], preventing the growth of other unsafe molds[9], and aiding in processes involved in cheese formation[10]. Uniform and rapid growth of Penicillium camemberti prevents the growth of unsafe molds that can cause food spoilage[9]. A primary difference between safe and unsafe molds is their ability to produce harmful substances[10]. Given that Penicillium camemberti does not produce mycotoxins or antibiotics during the production of the soft-ripened cheeses, it is a safe, consumable yeast. Mycotoxin producing yeasts are unsafe as these toxins are harmful to humans with the potential to cause injury or disease[11]. Although Penicillium camemberti is known to potentially produce mycotoxins, proper manufacturing practices and storage conditions prevent any significant concentrations to be detected in the cheeses, thus rendering the mold (and subsequently, the cheese) safe for consumption[12]. Antibiotics are beneficial when used in medicine, but can be unsafe when used elsewhere. Susceptible individuals are at risk of experiencing anaphylactic reactions, secondary to consuming a penicillin producing yeast[13]. Antibiotic production in undesired areas may also result in the emergence of bacterial resistance, creating unsafe, drug resistant bugs.

Prevention of food borne illnesses from soft cheese

In order to prevent the occurrence of food borne illnesses in cheese, particularly in brie and other soft and soft-ripened cheeses, many microbial risk assessments are conducted to ensure the safety of the cheese prior to packaging and distribution[14]. Risk assessments in brie are specifically aimed towards preventing and regulating the bacterium, Listeria monocytogenes, responsible for listeriosis[14]. During the assessment, predictive and mathematical models are used to evaluate the risk from L. monocytogenes, and the impact of varying manufacturing factors—such as water activity, pH, time, and starter culture—on the amount of L. monocytogenes, therefore evaluating the risk remaining in the cheese[15]. For example, using raw milk instead of pasteurized milk during manufacturing increases the risk of Listeriosis in brie and other soft-ripened cheeses[15]. The process of microbial assessment also consists of: hazard identification, exposure assessment, hazard characterization, and risk characterization[14]. This process once again aims to understand the conditions in which L. monocytogenes survives and grows, allowing food scientists to determine the optimal conditions during brie manufacturing.

Ways to Eat Brie Cheese

- Brie on bread or crackers is a simple and convenient way to enjoy the cheese.

- Pairing brie with fruits or nuts helps complement the flavors of both ingredients.

- Certain wines and beers pair well with brie. Wines that are more dry and acidic work better and beers such as porters and stouts pair well with brie.

- Brie can also be cooked. An example includes Brie on a fillet of salmon and then baked in the oven. Brie on sandwiches is also delicious when toasted and subsequently melted.

Potential Exam Question

Brie cheese has a characteristic layer of Penicillium camemberti on top which is considered a ‘good’ mold. What is/are the difference(s) between this mold when compared to ‘bad’ molds? (select all that apply)

A. Penicillium camemberti does not actively produce harmful substances, such as mycotoxins and antibiotics.

B. Penicillium camemberti produces both harmful and non-harmful substances; however, the non-harmful substances outweigh the harmful.

C. Penicillium camemberti adds to the flavour and texture of the cheese.

D. Penicillium camemberti prevents the growth of unsafe molds, which cause food spoilage.

Answer: A, C, D.

P. camemberti is a consumable yeast, safe from mycotoxins and antibiotics. It is also responsible for the breakdown of proteins inside brie and other soft-ripened cheeses, contributing to its creamy texture and distinct flavour. P. camemberti prevents the growth of molds that cause food spoilage, otherwise known as ‘bad’ molds.

References

- ↑ Dalby, Andrew (2009). Cheese: A Global History. Reaktion Books.

- ↑ 2.0 2.1 2.2 2.3 2.4 2.5 2.6 2.7 Moez, Sanaa; Coroller, Louis; Cerf, Olivier (April 13, 2004). "Risk assessment of LISTERIOSIS linked to the consumption of two soft cheeses made from RAW Milk: Camembert of Normandy and Brie of Meaux". Risk Analysis. 24: 389–399. doi:https://doi.org/10.1111/j.0272-4332.2004.00440.x Check

|doi=value (help) – via Wiley Online Library. - ↑ 3.0 3.1 3.2 3.3 3.4 Davidson, Alan; Jaine, Tom (2014). The Oxford Companion to Food. Oxford University Press. ISBN 9780199677337.

- ↑ 4.0 4.1 4.2 4.3 Abbas & Dobson, A. & A.D.W (2011). "Yeasts and Molds | Penicillium camemberti". Encyclopedia of Dairy Sciences (Second Edition): 776–779 – via Science Direct.

- ↑ Leclercq-Perlat, M.N. (2011). "Cheese | Camembert, Brie, and Related Varieties". Encyclopedia of Dairy Sciences: 773–782 – via Science Direct.

- ↑ 6.0 6.1 McSweeney, Patrick (2007). "Cheese Problems Solved". Food Science, Technology and Nutrition: 159–162 – via Woodhealth Publishing.

- ↑ 7.0 7.1 Rodriguez-Aguilera, Rocio (2011). "Effect of modified atmosphere packaging on quality factors and shelf-life of surface mould ripened cheese: Part I constant temperature". LWT - Food Science and Technology. 44: 330–336 – via Science Direct.

- ↑ President Cheese. "CAN YOU EAT THE RIND ON BRIE?".

- ↑ 9.0 9.1 Vokes, Taylor. "Potential Export of a Canadian Penicillium Candidum Culture for Cheesemaking in Nepal" (PDF).

- ↑ 10.0 10.1 Epstein, Eli. "Here's Why The Mold In Bleu Cheese Is Safe To Eat".

- ↑ Liew, Winnie-Pui-Pui. "Mycotoxin: Its Impact on Gut Health and Microbiota". Frontiers in Cellular and Infection Microbiology. 8: 1–17.

- ↑ Hymery, Vasseur, Colton, Mounier, Jany, Barbier, Coton, Nolwenn, Valerie, Monika, Jerome, Jean-Luc, Georges, Emmanuel (June 2014). "Filamentous Fungi and Mycotoxins in Cheese: A Review". Comprehensive Reviews in Food Science and Food Safety. 13: 437–456.CS1 maint: multiple names: authors list (link)

- ↑ Laich, Federico. "Production of Penicillin by Fungi Growing on Food Products: Identification of a Complete Penicillin Gene Cluster in Penicillium griseofulvum and a Truncated Cluster in Penicillium verrucosum". Applied and Environmental Microbiology. 68: 1211–1219.

- ↑ 14.0 14.1 14.2 Choi, Lee, Lee, Kim, Yoon, Kyoung-Hee, Heeyoung, Soomin, Sejoung, Yohan (March 2016). "Cheese Microbial Risk Assessments — A Review". Asian-Australasian Journal of Animal Sciences. 29: 307–314.CS1 maint: multiple names: authors list (link)

- ↑ 15.0 15.1 "Joint FDA / Health Canada Quantitative Assessment of the Risk of Listeriosis from Soft-Ripened Cheese Consumption in the United States and Canada". FDA. November 21 2017. Retrieved August 14 2021. Check date values in:

|access-date=, |date=(help)