Course:FNH200/Projects/2023/The Processing and Chemical Reactions of Soy Sauce

Introduction

Soy sauce loved globally for its savory umami taste has a history spanning over two thousand years. Originating in ancient China as "jiang," a blend of fermented soybeans, salt, and grains, it diversified into regional styles. Japan embraced it as "shoyu," with a milder taste due to more wheat and less salt. Its popularity spread across southern East Asia—Korea, Malaysia, and beyond—adding a distinct touch to local cuisines. Beyond flavouring, soy sauce became a staple in many marinades, dips, and stir-fry dishes, creating a connection between many diverse culinary cultures.

Enzymes in Soy Sauce

Soy sauce is fermented in a two-step process.

- First step is koji (solid state) fermentation with mould[1]

- Starter mould Aspergillus oryzae is introduced to a mixture of cooked soybeans and roasted wheat flour.[1] The inoculated koji culture releases protease enzymes which hydrolyze soy bean proteins into amino acids (notably glutamic acid), and amylase enzymes which hydrolyze wheat starch into simple sugars.[1]

- Second step is moromi (brine) fermentation with lactic acid bacteria and yeast[1]

- Lactic acid bacteria and yeast is added to the mixture and transferred to a vessel where it is then mixed with 20% salt brine resulting in a soybean mash called moromi.[1]

- The osmophilic lactic acid bacteria, Pediococcus halophilus, is added to metabolize the simple sugars into lactic acid and acetic acid.[2] During this process, the pH of the maromi drops from 6.5-7 to below 5.5.[2]

- The salt tolerant yeast, Zygosaccharomyces rouxii, converts remaining sugars to ethanol coinciding with the drop in pH.[1] This alcoholic fermentation contributes to the production of volatile phenolic compounds adding to the signature aroma and the glutamic acid from protein breakdown adds to the umami taste of soy sauce.[2]

Fermentation of Soy Sauce and Maillard Browning Reaction

- The first stage (koli) of fermentation lasts only a few days at a temperature around 40℃[2]

- The second stage (moromi) of fermentation varies dramatically in length from about 3 months to 3 years around 45℃ degrees.[2]

- Longer fermentation is believed to allow for the production and release of more flavour compounds leading to a fuller bodied taste and therefore a higher quality soy sauce.[1]

- The relatively high temperature of fermentation leads to Maillard reactions between amino acids and sugars contributing to the dark brown colour.[3]

- Many of the signature flavours present in soy sauce such as the malty, caramel-like, roasted, and nutty profiles are a result of Maillard reactions, and therefore during cooking at high temperatures these aromas are awakened from further browning reactions.[3]

Processing Methods to Prevent Spoilage and Pathogenic Microorganism Growth

- The fermentation process contributes greatly to preventing spoilage/pathogenic growth. As soy beans are soaked during koji fermentation (1st stage fermentation), fungi inhibitors are removed to facilitate growth of fungi and spontaneous fermentation occurs, dropping the pH of soy beans to 4.5-5.0. Low pH limits the growth of spoilage causing microorganisms and supports the growth of fungi necessary for lactic acid production in koji fermentation. [4]

- In the second stage of fermentation, called moromi, a high brine solution of 18-22% sodium chloride (NaCl) further restricts the growth of spoilage microorganisms and pathogens. During the moromi process, the pH further drops between 4.0-5.0 which decreases bacteria growth, while increasing yeast growth.[4] In the case of low-sodium soy sauce, Chiou (1999) found that the substitution of NaC; with ethanol help prevent pathogenic and spoilage causing micro organisms.[5] However the use of ethanol may prevent the growth of good microorganisms necessary for fermentation.[4] Furthermore, bacteria that facilitates fermentation produces lactic acid. Lactic acid produces substances which have antimicrobial effects toward spoilage-causing microorganisms.[6]

Stability of Soy Sauce in Room Temperature

Due to the low water activity and high salt content, soy sauce is able to be stored safely at room temperature, without refrigeration.[7] Since soy sauce has a high sodium level and salts are water-binding agents, there is more bounded water than free water, which contributes to having a low water activity and controls the growth of certain microorganism.[8] Salt can also act as a preservative to slow down the rate of bacteria and microbe growth and which helps extend shelf-life when unopened. [9]

Indefinite Expiry of Soy Sauce

Shelf life of food is usually affected according to its microbial status. The use of pasteurization inactivates organisms or enzymes which cause food spoilage. Ansah, H. K. (2011) found that changes in microbial numbers did not change drastically over the course of 6 months after pasteurization, which contributed to the stability of soy sauce on the shelf. [10] Changes in flavour, odour or composition, are often signs soy sauce has spoiled. As a result, proper storage can facilitate in prolonging the shelf life of soy sauce. Factors such as light, temperature fluctuations and the amount of time the bottle is opened can degrade the quality of fermented goods, such as soy sauce.[6] Further more, the type of packaging may affect the longevity of soy sauce. PET allows more oxygen to permeate through as opposed to glass, which results in stronger oxidation reactions to occur. However it is important to note that changes in phenols (flavouring compounds) found in soy sauce stored in plastic or glass did not change drastically. It was found that oxygen permeating PET plastic had a stronger effect during the bottling phase as opposed to the storing phase.[11]

Different Types of Soy Sauce (Specifically Light, Dark, Regular, Low-Sodium)

Dark Soy Sauce

- The dominant components are sweet and salty.

- The sensory attributes such as color, caramel odor, viscosity and sweetness taste increase the overall acceptance in these types of soy sauce.

- Has thick consistency

- Typical aroma because it was heat processed with palm sugar[12]

- The sensory attributes such as color, caramel odor, viscosity and sweetness taste increase the overall acceptance in these types of soy sauce.

Light Soy Sauce

- This allows the saltiness and umami taste to be the sensory attributes for light soy sauce

- Thinner consistency

- With higher amounts of added salt

- Special process (Tamari Shoyu - a Japanese soy sauce)

- Process: fermented soy beans (rich in umami compounds[12]

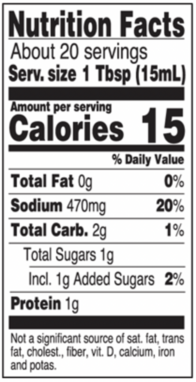

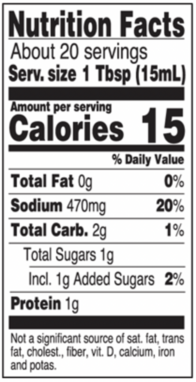

Less-Sodium Soy Sauce Ingredients: Water, Soybeans, Sugar, Salt, Vinegar, Alcohol, Lactic Acid

Low-sodium vs Regular Soy Sauce

- Less sodium soy sauce is also known as tamari

- Less soy sauce is still not considered as “low sodium” because it contains more than 190 milligrams of sodium for one teaspoon of soy sauce, which does not come under the criteria for low sodium labeling as that is 140 milligrams or less. [13]

Umami Flavor and Saltiness of Soy Sauce

Umami Flavor of Soy Sauce

- The fermentation process of soy beans, which are the raw material in soy sauce, gives the distinct taste of the sauce. Free amino acids play an important role to the umami taste, in the presence of sodium salt. The Umami flavor comes from the breakdown of proteins found in soybeans, releasing amino acids. The most common amino acid found in soybeans is glutamic acid. The release of this acid results in the umami flavour of Japanese soy sauce specially. [14]

- Monosodium L-glutamate (MSG) is the sodium salt form of free L-glutamic acid, an acidic amino acid. Acidic amino acids such as L-glutamic acid and L-aspartic acid has a sour taste in dissociated state, but their sodium salts dissociated in aqueous solutions can elicit an umami taste.[14]

- Glutamate and aspartate are amino acids that are building blocks of proteins. So When soybean is broken down there is high concentration of these amino acids.[14]

Saltiness of Soy Sauce

The saltiness is mainly because of the presence of NaCl. Some soy sauce use brine (a high concentration solution of salt typically sodium chloride or calcium chloride), which makes the sauce more salty. [15]

Exam Question

Soy sauce is fermented in 2 steps. The first step, ___1___ fermentation, involves the ___2___ ___3___. The second step, ___4___ fermentation, involves the addition of ___5___ which metabolizes simple sugars, and ___6___ which produces alcohols.

Answers:

1 - koji (solid state)

2 - mould

3 - Aspergillus oryzae

4 - moromi (brine)

5 - lactic acid bacteria

6 - yeast

This question should be included on the exam because it tests knowledge on topics covered in lesson 9 such as microbial antagonism, fermentation, yeasts, moulds, and lactic acid bacteria. It applies the content of this course to a food that is used in our everyday lives, while introducing Aspergillus oryzae, a new example of "good mould microorganism".

Resources

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 1.6 Syifaa, Alam; Jinap, Selamat; Sanny, Maimunah; Khatib, Alfi (August 11, 2016). "Chemical Profiling of Different Types of Soy Sauce and the Relationship with its Sensory Attributes". Journal of Food Quality. 39: 715 – via Wiley.

- ↑ 2.0 2.1 2.2 2.3 2.4 Lioe, Hanifah; Selamat, Jinap; Yasuda, Masaaki (April 5, 2010). "Soy Sauce and Its Umami Taste: A Link from the Past to Current Situation". Wiley. 75 – via IFT.

- ↑ 3.0 3.1 Diez-Simon, Carmen; Eichelsheim, Charlotte; Mumm, Roland; Hall, Robert (September 3, 2020). "Chemical and Sensory Characteristics of Soy Sauce: A Review". Journal of Agricultural and Food Chemistry. 68 – via ACS Publications.

- ↑ 4.0 4.1 4.2 Devanthi, Putu Virgina Partha; Gkatzionis, Konstantinos (June 2019). "Soy sauce fermentation: Microorganisms, aroma formation, and process modification". Food Research International.

- ↑ Chiou, R.Y (1999). "Salt-free Miso Fermentation Using Ethanol, Sugars, and Polyols". Journal of Food Science.

- ↑ 6.0 6.1 "UBC Canvas FNH 200 9.3 Fermentation".

- ↑ Luh, B.S. "Industrial production of soy sauce". Springer Link.

- ↑ "UBC Canvas FNH 200 2.2.1.4 Water".

- ↑ Shahar, Suzana; You, Yee Xing (May 27, 2019). "Sodium content in sauces—a major contributor of sodium intake in Malaysia: a cross-sectional survey". DMJ Open.

- ↑ Ansah, Hannah. "CHARACTERIZATION OF MICROORGANISMS INVOLVED IN THE SECOND STAGE OF SOY SAUCE FERMENTATION (MOROMI) AND STUDIES ON THE SHELF LIFE OF SOY SAUCE". KWAME NKRUMAH UNIVERSITY OF SCIENCE AND TECHNOLOGY,. line feed character in

|journal=at position 40 (help)CS1 maint: extra punctuation (link) - ↑ "Characterizing the effect of packaging material and storage temperature on the flavor profiles and quality of soy sauce". National Library of Medicine.

- ↑ 12.0 12.1 Syifaa, Shah Alam; Jinap, Selamat; Sanny, Maimunah; Khatib, Alfi. "Chemical Profiling of Different Types of Soy Sauce and the Relationship with its Sensory Attributes". Journal of Food Quality.

- ↑ Smith, Jenna. "Soy Sauce Varieties: What's the Best Option?".

- ↑ 14.0 14.1 14.2 Lioe, Hanifah Nuryani; Selamat, Jinap; Yasuda, Masaaki. "Soy Sauce and Its Umami Taste: A Link from the Past to Current Situation". Feeding the minds that feed the world.

- ↑ Luh, B.S. "Industrial Production of Soy Sauce". Industrial Microbiology.