Course:FNH200/Projects/2022/Cheese Fondue- processes involved in preparation

CHEESE FONDUE

We were walking downtown when we saw a restaurant that serves fondue and knew we wanted to make our project on it. The intoxicating smell, the mouth watering aroma and the melting cheese convinced us to know more about the preparation of this delicacy.

HISTORY OF FONDUE

Cheese Fondue is a very popular dish from Switzerland. It involves the process of melting the cheese with the addition of seasoning, starch and wine. Fondue, derived from the French word "fondre," which means "to melt," originated in 18th century Switzerland as a way for farms to stretch their meagre resources during the winter months. The family may gather around the hearth with some leftover cheese, old bread, and a splash of wine. Bread was only prepared on rare occasions in Alpine farm settlements, so whatever bread was available was generally stale. The bread softened and turned scrumptious after being dipped in the melted cheese. Fondue evolved from these humble origins into a Swiss winter tradition. Despite its rural origins, fondue's presence at the Swiss table was not restricted to the farmer and peasant elite; rather, it was more commonly appreciated by those of wealth. Fondue's great popularity was part of the Swiss Cheese Union's (Schweizerische Käseunion) 1930s drive to encourage cheese usage in Switzerland.

Following the end of rationing after World War II, the Swiss Cheese Union restarted its successful campaign, this time touting fondue as the Swiss national meal and a symbolic of Swiss unity and cultural pride. Fondue was also included in the Swiss military's cookbooks.

PRESERVATION

Any cheese is known to be a Gastronomic product which is served with Wine or alongside meals. As a well loved product, its storage and preservation technique is essential to keep it fresh and maintain its texture and flavour. Allowing the cheese to breathe is crucial to prevent it from getting dry or crusty.

The fermentation process results in chemical formations which are preservatives added to foods. Certain foods in which pH levels are lower than 4.6 support the growth process of Clostridium Botulinum. Wine and Cheese have a low acid tendency henceforth they are used as part of the process of fermentation.

PRESERVATION PRINCIPLE

Preservation Principle states that any form of preservation should encourage the growth of acid-producing microorganism which in turn suppress the metabolic growth. Microbial Antagonism is known to be the principle of preservation which occurs in the production of fermented products. They produce end results of alcohols which play a role of antimicrobial agents.

FERMENTATION OF CHEESE

"Cheese is a fermented dairy product made by coagulating casein, removing whey, compressing and molding by adding lactic acid bacteria (LAB), rennet, and acid to milk or cream. The major role of LAB in cheese fermentation is that LAB can decrease pH values by producing various organic acids. The low pH of cheese affects its texture and rheological properties directly related to chemical changes in the protein network of cheese curd (Kim et.al, 2021)."

Melted cheese in fondue is made of Emmental and Gruyère cheeses. These need to be fermented before they are consumed in their well known forms. Lactic acid bacteria introduced with propionic acid bacteria is the microorganism used to ferment the cheese. It is a starter culture that grows rapidly under favourable conditions to produce desirable by-products of metabolism (enzymes in this case).

“The flow behavior or rheology of fondue is crucial for mouthfeel, flavor release, and the tendency of fondue to cling to the bread. Fondue is a complex multiphase system whose rheology is determined by the interactions of its colloidal ingredients. We establish cheese fondue as a water-continuous system with dispersed fat droplets, charged caseins, and starch granules. Irreversible phase separation, a common issue in fondue preparation, may be prevented by addition of a critical minimum starch concentration (Bertsch et.al, 2019)”.

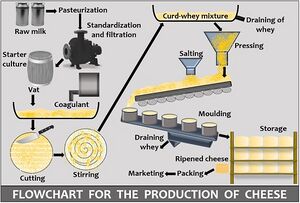

The Fermentation Process is briefly described below:

Setting the milk

- Lactic acid culture is added to pasteurised milk

- As the milk turns mildly acidic, rennet (or enzyme is added): The rennet and acid combine to coagulate the milk protein 'casein'. This forms a gel, similar to the one found in yogurt.

- The rennet (enzyme) hydrolyses the casein protein which causes the micelles to change from being calcium stable to calcium sensitive, leading to the formation of a coagulum. Whey is trapped within the curd.

Curd cutting

Whey is further removed from the curd by cutting it into cubes. The production of lactic acid during this phase further expels the whey out.

Cooking

Cooking the cut curds at 38°C furthermore accelerates lactic acid production, i.e. accelerated the expulsion of whey from cut curds.

Draining and matting

Once the curd cubes settle and the whey is drained from the cheese, the curd cubes are matted and fused together to form a rubbery slab. Casein micelles interact with one another along the edges of the curd to promote fusion.

The cheese is then cut into blocks in a process known as 'Cheddaring'. The blocks are piled onto one another, turning each block every 15 minutes.

Salting

The cheddar curd is cut and salted. Salt serves as a way of-

- drawing the remaining whey out

- adding flavour to the final cheese

- to inhibit growth of proteolytic and lipolytic spoilage-causing microorganisms that may be associated with the newly formed milled curd;

- to provide conditions favourable to the proteolytic action of the rennet and of the proteinases of the lactic acid starter during ripening of the cheese.

Curing and ripening

During curing the curd is knit together such that the curd junctions are not visible in a good quality cheese. To check the quality of cheese, one can see if the cheese tends to fracture along junction lines. Cheese in which the junctions are clearly visible tends to have a crumbly rather than a smooth texture.

The cheese is placed in a cool room for 3-4 days, vacuum packed in a flexible film or dipped in hot paraffin (in order to prevent mould growing on the surface of the cheese. Ripening of a cheese can last from days to months. (depending on the flavour and aroma desired)

PRODUCTION OF SWISS CHEESE

Swiss cheese is a hard type of cheese. It's fermentation process begins much like that described above, with the addition of a secondary bacteria culture (Propionibacterium shermanii, which is added to the milk along with the lactic acid starter bacteria). Two starters are used for production of Swiss cheese namely; Streptococcus thermophilus and Propionibacterium shermanii.

| Streptococcus thermophilus | Propionibacterium shermanii |

| - Is heat tolerant, allowing the acid to still be produced at higher cooking temperatures. | - Another bacterium used as a starter culture.

- It produces propionic acid and carbon dioxide (from lactic acid). - Also produces proline (amino acid). - Proline- Imparts the sweet taste of swiss cheese - Propionic acid- Contributes to the flavour of Swiss cheese. - Carbon dioxide- forms holes (eyes) in the cheese during aging. |

SENSORY SCIENCE OF FONDUE

“The flow behavior or rheology of fondue is crucial for mouthfeel, flavor release, and the tendency of fondue to cling to the bread. Fondue is a complex multiphase system whose rheology is determined by the interactions of its colloidal ingredients. We establish cheese fondue as a water-continuous system with dispersed fat droplets, charged caseins, and starch granules. Irreversible phase separation, a common issue in fondue preparation, may be prevented by addition of a critical minimum starch concentration (Bertsch et.al, 2019)”.

POTENTIAL QUESTION

Change exam question to quiz format before submission

Q- Fondue originated in the mountains of Switzerland, why did it originate in cold climate and how do fats keep our body warm?

A) fats acts as insulators

B) fats release heat

C) fats are tasty

D) cold temperatures trigger certain fat cells, called brown adipose tissue to release stored energy in the form of heat to burn calories.

Ans- D ; This is the basis of the biological process of metabolism which provides heat to our body.

PACKAGING AND STORAGE OF PROCESSED CHEESE

The final product should be stored at temperatures below 10°C, although such low temperatures may include crystal formation. The relative humidity of air is also controlled in storage rooms of processed cheese. Storage rooms are free of pests and are sterilised accordingly. Processed cheese is packed at a temperature of ≥75°C to prevent the development of any potential microbiological contaminants from the environment or from the packaging material. At the stage of processing, the microbiological hazards can be caused from the environment. Thus, packaging materials must be sterilized to prevent the presence of yeasts and molds. Processed cheese may be contaminated with fragments from the packing materials used (e.g., foil, glue, labels, cardboard, clips) or metal fragments from the packing machine. Regardless of the cheese form, processed cheese is packaged in the absence of oxygen to inhibit molds growth.

SPOILAGE IN CHEESE

A food can be considered spoiled when it is no longer edible or acceptable to consumers or does not meet the quality characteristics that its producer or manufacturer deems optimum. Foods spoil as a result of both natural biochemical changes and changes caused by microorganism growth and metabolism. The latter involves the degradation of proteins, carbohydrates, and fats by microorganisms or microbial enzymes. Signs of spoilage include changes in appearance, taste, odor, and texture. The type of spoilage depends on the original microflora of a product; the product’s physical and chemical characteristics; and how it is processed, packaged, and stored.

Lactobacilli commonly occur in natural cheese because they are used as a starter culture. Under low-oxygen and acidic conditions, certain lactic acid bateria become the predominant spoilage organisms of a variety of foods. LAB are the predominant bacteria in raw milk. Although refrigeration suppresses growth of LAB, psychrotrophic bacteria such as Pseudomonas can grow and produce rancid or putrid odors. Pasteurization kills LAB and the psychrotrophs, but some spores of Bacillus and Clostridium can survive pasteurization and grow slowly at refrigeration temperatures.

References

Bertsch, P., Savorani, L., & Fischer, P. (2019). Rheology of swiss cheese fondue. ACS Omega, 4(1), 1103–1109. https://doi.org/10.1021/acsomega.8b02424

Chan, J. C. K. (2022, July). Food Preservation with Biotechnology; Fermentation. FNH200 Course Instructors.

Felfoul, I., & Attia, H. (2022, February 18). Packaging, cooling, and storage of processed cheese. Processed Cheese Science and Technology. Retrieved August 18, 2022, from https://www.sciencedirect.com/science/article/pii/B9780128214459000133#!

Khalid, N. M., & Marth, E. H. (2010, April 9). Lactobacilli - their enzymes and role in ripening and spoilage of cheese: A Review. Journal of Dairy Science. Retrieved August 18, 2022, from https://www.sciencedirect.com/science/article/pii/S0022030290789527

Kim, J.-A., Kim, G.-S., Choi, S.-M., Kim, M.-S., Kwon, D.-Y., Kim, S.-G., Lee, S.-Y., & Lee, K.-W. (2021). Hardening properties of cheeses by latilactobacillus curvatus PD1 isolated from hardened cheese-ddukbokki rice cake. Microorganisms, 9(5), 1044. https://doi.org/10.3390/microorganisms9051044

Mermelstein, N. H. (n.d.). The ICK factor: Microbial spoilage. IFT.org. Retrieved August 18, 2022, from https://www.ift.org/news-and-publications/food-technology-magazine/issues/2017/november/columns/food-safety-and-quality-microbial-spoilage#:~:text=Pseudomonas%20or%20Enterobacter%20can%20spoil,and%20molds%20can%20spoil%20butter.