Course:FNH200/Projects/2021/Maple Syrup

Maple Syrup is one of the most popular products in Canada. In fact, the leaf of this tree is the one that proudly shines on the national flag. It is an amber colored syrup that is extracted from the sap of maple trees. Its flavor is sweet, so it is often used in desserts such as waffles, crepes, and pancakes. As an emblem of the country, this viscous liquid can be found easily in the nation's supermarkets or even in specialist maple syrup stores.[1]

History

The sweet sap of the sugar maple (Acer saccharum) was known and valued by Indigenous peoples of the Eastern Woodlands, including the Abenaki, Haudenosaunee and Mi’kmaq, long before the arrival of European settlers. Haudenosaunee tradition tells of the piercing of the bark of a maple and the use of its “sweet water” to cook venison, a happy accident that might have also established the culinary technique of maple-cured meats. Maple curing was a food preservation method practised by the Anishinaabe that allowed communities to keep food stores for winter months when food was scarce.

The Anishinaabe called the "sugaring off" period when sap was collected the "maple moon" or "sugar month". The tradition of sugaring off became established in communities in the deciduous forests of North America and has survived to the present.[2]

Grading of Maple Syrup

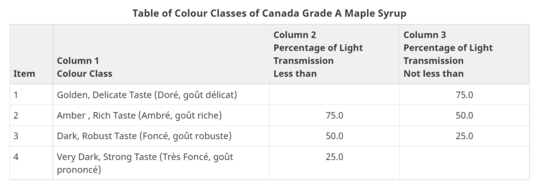

Beginning in 2015, new standards for grades of maple syrup were introduced by the International Maple Syrup Institute (IMSI), and the Canadian government has adopted the changes.[3]

There are two grades of maple syrup that is not imported "Canada Grade A" and "Canada Processing Grade" for grade names used for imported maple syrup. Here we only discuss the non-imported maple syrup, and there are four classification of Grade A maple syrup.[4]

- Grade A Golden with a Delicate Taste: Mildest in flavour and lightest in colour, golden maple syrup has a bit of a butter popcorn flavour. This grade is great for use on foods, not in foods. So poured on ice cream, pancakes or waffles. Drizzled over French toast or fresh cut fruit.

- Grade A Amber with a Rich Taste: A more medium maple flavour which is darker in colour. Amber maple syrup has a stronger flavour than golden and has a richer flavour that is a bit more maple. Amber maple syrup is great for use in foods or on foods. Use amber maple syrup on pancakes, waffles, French toast, in oatmeal or yogurt.

- Grade A Dark with a Robust Taste: A stronger flavour that is much darker in colour. Also a great choice for use in or on foods. Again, the traditional uses like pancakes and waffles are a great place for dark. But since it has a stronger flavour, dark maple syrup is great in things like smoothies, curry dishes and anything spicy that you want to add a little earthy sweetness too. Also great in tea, coffee and even baking.

- Grade A Very Dark with a Strong Taste: The strongest maple flavour and darkest colour. Very dark maple syrup is a favourite among bakers, chefs and those looking for a strong maple flavour. Very dark maple syrup, like dark, is great in foods such as smoothies, curry dishes and anything spicy that you want to add a little earthy sweetness too. Also a great choice for baking and preserves. Very dark maple syrup is also a great ingredient for the professional or amateur brewer.

Harvesting

Maple syrup is mostly made in the North Eastern part of North America and generally collected between February and April. Although maple trees grow all over the world, however it is only in North Eastern North America that the correct climate conditions allow maple sap to be harvested. In Spring, the temperature change brings cold night and warm days, also above freezing during the day and below freezing at night. This causes the maple sap to flow up and down the tree trunk so that it can be collected in buckets. Although the sease may last 2 to 3 months, the maple sap does not run everyday. The sap will only run when the temperature difference is sufficient to reach below freezing at nights and above freezing at warm days.[5]

Maple sap collected in traditional metal buckets will be boiled untill water evaporates. Due to large amount of heat and steam produced, this is typically done outdoor over a wood fire, or it can be also done on a propane burner. As the water boils off and the sap begins to reduce, the sugar begins to concentrate, and the temperature rises which is monitored using a candy thermometer. When the boiled sap reaches 219°F or 66% sugar content, it becomes maple syrup and ready to be further processed for sterilization and packaging. Since the maple syrup is prone to molding, the syrup will be filtered and pasteurized before filled into glass bottles, then refrigerated for storage.[6]

Packaging & Preservation

- Packaging: Maple syrup is commonly filled into metal, glass, or food-grade plastic containers. Syrup packaged in tin or glass can be stored for up to one year in the refrigerator in its original container.[7] And each has advantages and disadvantages as to maintaining the quality of the syrup in storage. [8]

- Tin or Metal: Using metal cans is the most traditional way to store the maple syrup. But one thing to notice is that the container needs to be very dry and clean before using. Tin or metal can maintains syrup quality for 11 to 12 months, and tin flavor can be picked up if stored for long periods.[9]

- Glass: Glass bottles are typically the best containers for keeping the syrup. They can be made into any traditional or modern shape, and can show off the beautiful colour of the syrup to the greatest extent as well as checking the syrup for cloudiness or sugar crystals. Glass can maintain the flavor of the maple syrup indefinitely. It may darken slightly, especially if the syrup is not kept in the dark. Also, glass containers are usually reserved for packaging small amounts—½ pints, pints, and quarts. It is a costly way to package and is often seen in gift packs.[10]

- Plastic: Also a popular packaging material. It is lightweight and easy to use. Syrup stored in plastic will usually maintain quality for 3 to 6 months. Plastic breathes, so a color and flavor change can be the result in long-term storage in plastic containers. However, new plastic containers have been developed to extend shelf life. The disadvantage to these, so far, is that the cost is more than the regular plastic jugs.[11]

- Preservation: The three main enemies of maple syrup are air, time, and temperature. So maple syrup should be stored in a cool, dark place immediately after purchase.[12][13]To quality product, it is highly suggested that to use within 2 years, and the syrup should be refrigerated again after opening.[14] If water is excessed or if the container is not clean after opening or before repackaging, there may be the growth of bacteria, yeast or mold during storage. It is not a proper way to simply remove the mold or reheat the product, because some microorganisms can produce toxins as they grow, and that will probably cause severe sickness. So the product should be discarded.[15]

Nutrient Ingredient & Chemical Composition

One 30 ml of pure maple syrup contains zero fat, 27g of carbohydrate, 35% of the daily need of Manganese and 15% for Riboflavin. It also contains handful amount of Calsium , Zinc, Potassium, Thiamin and Copper. Maple syrup is an ideal food for fitness people as it is made of carbonhdrates, which provides eough energy and helps maintian stamina. Manganese and Calcium support healthy bones, connective tissue, digestion and muscle function. Intaking Copper and Iron help to strengthen the immune system and nervous system.

The major carbohydrate in maple syrup is sucrose, although there are also small amounts of glucose and fructose. According to Stuckel and Low's research,[16] depending on the typed of the product, the sucrose content is from 51.7% to 75.6%. Glucose and fructose only account for 0 to 9.59% and 0 to 3.95% respectively. Malic Acid is the major organic acid that is found in maple syrup, ranged from 0.1 to 0.7%. Citric, succinic and fumaric acids are found, but their contents are very low.

Maillard reaction is one of the major chemical reactions involved during maple syrup prodcution. When the syrup is heated, it turns into darker color and stronger flavor. During the reaction, the producers need to control the invert levels in order to make a very high level of invert sugar. The level of invert sugar will affect the flavor and the grades.

Health Concerns

Pure maple syrup do not contain any artificial additives and sweeteners, and it contains up to 24 different antioxidants and numerous nutritional benefits. Compared with redined sugar, maple syrup has a lower score on the Glycemic Index.

However, maple syrup should be consumed moderatedly. Including maple syrup, over consuming any kind of sugar: glucose, fructose, sucrose, maltose, corn syrup, etc would lead to most health issues like diabetes, cancer and heart disease.

Production and Exportation

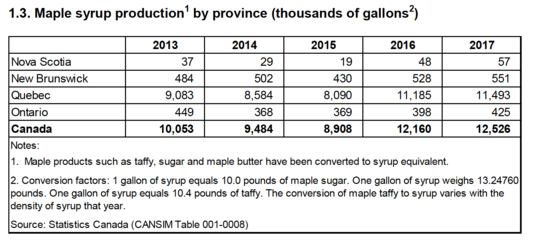

Canadian maple syrup industry accounts for approximately 71% of the world's maple syrup and is the leading global producer of maple products. Despite a production increase of 145% over the last decade, Canada's world share has fallen by 9% due to rising competition from the United States.

In 2017, Canada recorded the highest numbers in maple syrup production and value since the data started being collected in 1924. After experiencing a decrease in maple syrup production in 2014 and 2015, it reached 12.5 million gallons in 2017, up 41% from 2015 and 3% from 2016.[17]

Canada is the world's largest exporter of maple products, with exports valued at $382 million in 2017, nearly the same value as in 2016 and up 35% over the last five years. The province of Québec alone counts for 90% of the country's maple syrup production, and 97% of Canadian maple product exports.

Potential Exam Question

Question:

What is the most common and best sterilization method for maple syrup packaging?

A - Ionizing irradiation

B - Pasteurization

C - No need to sterilize, since the high sugar content will inhibit bacterial growth.

D - No need to sterilize, since the boiling from sap to syrup is beyond sterile.

Correct Answer: B

The boiling step will allow water evaporation and reach a temperature beyond the water boiling point, which should have killed most microbes. Also, the 66% sugar content should prevent converting spores to vegetative cells. However, boiling at 212° F for at least 15 minutes for pasteurization is still needed for packaging because during the storage and transport condensation drops occur in the bottle and fall to the syrup, an environment is created where fungal spores can develop. Maple syrup is not irradiated since it contains ionization unstable chemicals like thiamine, while pasteurization already suffice the need for sterilization and a long shelf life.

Explanation for it to be on the final:

Our group finds maple syrup an interesting food to study since it contains many minerals and cofactors for cell growth. We find that although there are many social media platforms where people discuss the need and requirement for maple syrup sterilization, there are limited amount of scientific reference for its sterilization methods and packaging. Nonetheless, its sterilization and storage is still interesting, since it involves knowledge of high sugar content vs. microbial growth conditions and sterilization methods.

References

- ↑ "FOOD IN CANADA".

- ↑ "Maple Syrup Industry".

- ↑ "Grades of Syrup".

- ↑ Government of Canada. "Maple Syrup Grade Requirements".

- ↑ Allaway, William. "When is Maple Syrup Made".

- ↑ Davenport, Anni. "Maple Syrup Production for the Beginner".

- ↑ Gold, Betty. "You've Been Storing Maple Syrup Wrong Your Entire Life—Here's How to Keep It Fresh". REAL SIMPLE.

- ↑ Drake, Barbara H. (Feb 25, 2010). "Selecting, Storing, and Serving Ohio Maple Syrup". Ohioline.

- ↑ Drake, Barbara H. (Feb 25, 2010). "Selecting, Storing, and Serving Ohio Maple Syrup". Ohioline.

- ↑ Drake, Barbara H. (Feb 25, 2010). "Selecting, Storing, and Serving Ohio Maple Syrup". Ohioline.

- ↑ Drake, Barbara H. (Feb 25, 2010). "Selecting, Storing, and Serving Ohio Maple Syrup". Ohioline.

- ↑ "Focus on Food Safety When Making Maple Syrup" (PDF).

- ↑ Drake, Barbara H. (Feb. 25, 2010). "Selecting, Storing, and Serving Ohio Maple Syrup". Ohioline. Check date values in:

|date=(help) - ↑ "Making Maple Syrup" (PDF).

- ↑ Drake, Barbara H. (Feb. 25, 2010). "Selecting, Storing, and Serving Ohio Maple Syrup". Ohioline. Check date values in:

|date=(help) - ↑ Stuckel, Jackie. "The chemical composition of 80 pure maple syrup samples produced in North America".

- ↑ "Statistical Overview of the Canadian Maple Industry 2017".