Course:FNH200/Projects/2020/The Food Science Behind Ice Cream

Introduction

With an industry worth $11 billion, ice cream is recognized as the most popular category of frozen desserts. Each year, the average American is found to consume more than 23 pounds of the dessert.[1] Since it is typically consumed during warmer months, most of its production occurs during March to July, with July being the busiest month.

The first ice cream-like dessert was created in China in 200 BC when a rice mixture was combined with milk and was frozen by being packed into snow.[2] It was first consumed in 618-97AD by King Tang of Shang, who had 94 ice men create a similar dessert using buffalo milk, flour and camphor. Ice cream was then introduced to Italy as the European explorer Marco Polo appeared to witness and bring back descriptions of its production in China during his travels. Today, ice cream is primarily produced from cream or butterfat, combined with milk, sugar and flavourings. While the most popular flavours are vanilla, strawberry and chocolate, there have been hundreds of flavours created worldwide.[3]

Packaging

The main concern in packaging ice cream is protecting the product while keeping the cost at a minimum. Packaging is required to protect product from damage and contamination, provide labeling for customers (nutritional values, ingredients, bar code etc), make it more appealing to customers and allow transportation and storage of product effectively.[4]

Ice cream containers come in materials such as firm-walled plastic, plastic-coated paper, disposable waxed paper cartons and even plastic flexible bags. The type of container used is especially significant in frozen foods, like ice cream, such that it should be resistant to the transfer of water vapor within the freezing unit from the food to the dry environment. Due to cold temperatures, glass is not an ideal packaging material as it is susceptible to shattering or breaking when stored in these conditions. The materials are chosen to prevent issues such as spoilage, contamination and damage to the product.[5]

Another prevention when choosing the packaging for ice cream is to find a material that stops the formation of pinholes during shipment or general handling as these holes expose the food directly to cold temperatures and can possibly promote “freezer burn” (a phenomenon that causes the formation of package ice and freeze dehydration to develop on ice cream due to the loss of moisture in the food).[6]

Processing

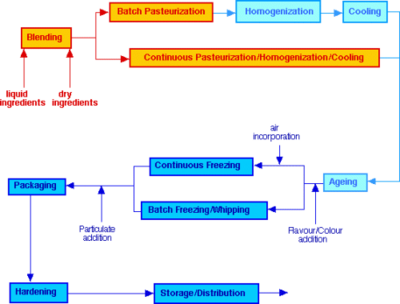

The steps of manufacturing ice cream are in the following order:

Blending Ice Cream Mixture

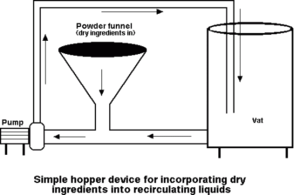

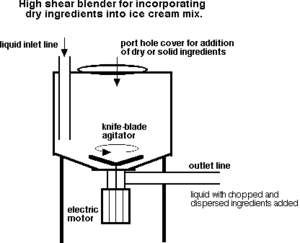

Ingredients are selected on desired formulation, liquid and dry ingredients. Milk fat source, nonfat solids, stabilizers and emulsifiers are blended to create ice cream mixture (liquid + solid).[7]

Blending requires rapid agitation to incorporate powders, and often high speed blenders are used.[7]

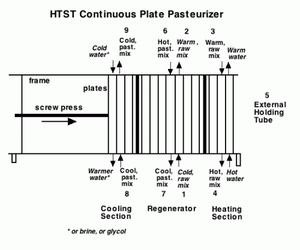

Pasteurization

Ice cream mixed is pasteurized at 79.4C for 25 seconds, this helps to reduce the number of spoilage organisms such as psychrotrophs, and helps to hydrate some of the components (proteins, stabilizers). Ontario regulations for pasteurization are: 69° C/30 min. 80° C/25s. Ice Cream processing utilizes both batch and HTST pasteurization methods. [7]

Homogenization

Ice cream is homogenized (2500-3000 psi) to decrease milk fat globule size, increase surface area and form a membrane. Homogenization provides better emulsion, smoother, creamier ice cream and ensures emulsifiers and stabilizers are evenly distributed. Additionally, homogenization gives a greater apparent richness and palatability, better air stability and increases resistance to melting.[7]

Aging

Ice cream is aged at 5C for at least 4 hours to overnight. Aging cools down mixture before freezing. Milk fat is partially crystallized and protein stabilizers are hydrated to improve whipping qualities and texture. Aging is performed in insulated or refrigerated storage tanks or silos.[8]

Liquid Flavouring

Liquid based flavors and colors are added.[8]

Freezing

Mixture is frozen while incorporating air. Continuous freezers utilize a knife-blade agitator that continually scrapes the surface of the freezing barrel. The ice cream mix is pumped from a bulk tank to the freezing barrel and the air is incorporated with another pump just before it enters the freezing barrel. Up to 50% of the volume of ice cream incorporates air. 50% of ice cream is frozen at this point. Soft serve ice cream is generated at this point.[7]

Solid Flavoring

Fruit, swirls, nuts, candy are added at this point, ensures flavorings are easily mixed, remain whole.[8]

Packaging

Ice cream is packaged.

Hardening

Ice cream is rapidly cooled to less than -25C, creating small ice crystals. Storage at this temperature stabilizes ice crystals and maintains product quality. A small portion of the final product is liquid water, to ensure product softness.[8]

Spoilage

Spoilage Caused by Microorganisms

Bacteria, molds, and yeasts are known to be able to grow in ice cream.[9]

These microorganisms might be present in the ingredients used for ice cream production. Depending on the ingredients used, different microorganisms might be present. Manufacturers using fresh fruit, need to be aware of the presence of yeast and molds. The sugar used could be contaminated with different types of fungi. Additionally, milk needs to be analyzed for the presence of unwanted microorganisms.[10] The ingredients mentioned above go through different treatments in order to eliminate unwanted microorganisms. Each ingredient is tested for total bacterial count, and ingredients surpassing the allowed maximum bacterial count are not used during ice cream production.

One of the main food safety concerns during ice cream manufacturing is the presence of Listeria monocytogenes, a bacterium able to grow in temperatures as low as 0 C. This bacterium is known to need a moist environment to grow, and it is for this reason that floors in ice cream factories are to be kept drained and as dry as possible. Another bacterium whose presence causes concern is Staphylococcus aureus, as it is able to produce a heat stable toxin able to infect those consuming spoiled ice cream.[10]

To eliminate unwanted microorganisms, ice cream is pasteurized at a temperature of 70C for 10-30 minutes. Following pasteurization, ice cream is immediately frozen. Although the pasteurization and freezing steps can eliminate any pathogenic microorganisms present, additional pathogenic microorganisms can be introduced through unclean utensils, faulty handling, or from infected food handlers. Ice cream factories must participate in routine inspections and different microbial tests are performed.[10]

Exam Question

Q. Why are ice cream package containers made up of materials such as firm-walled plastic, plastic-coated paper, disposable waxed paper cartons and even plastic flexible bags?

- These package materials are resistant to the transfer of water vapour within the freezing unit from the food to the dry environment.

- These materials are chosen to prevent issues such as food spoilage, microorganisms and damage to the final product

- Resistant to pinhole formation

- Prevents freezer burn

- All of the above

This is an excellent question for the final exam as it encompasses several elements we have studied in class. For example, selecting appropriate packaging materials is key in preventing or slowing down food spoilage. In addition, the prevention of pathogenic microorganisms is of utmost importance for the safe consumption of foods. The question also provides insight into food preservation techniques as well as freezer burn and preventing the dehydration of a food product. Lastly, the question provides insight into the ice cream packaging process, which provides information on how ice cream maintains its quality during storage and distribution for our personal enjoyment.

References

- ↑ http://idfa.org/ice-cream-sales-trends#:~:text=The%20average%20American%20consumes%20more,popular%20category%20of%20frozen%20desserts.

- ↑ http://news.bbc.co.uk/cbbcnews/hi/find_out/guides/tech/ice-cream/newsid_3634000/3634978.stm

- ↑ https://www.britannica.com/topic/ice-cream

- ↑ "Packaging of Ice Creams". ATP Engineering and Packaging. 2012. Archived from the original on 2012. Retrieved 13/08/2020. Check date values in:

|access-date=(help) - ↑ Marshall, Robert (2003). "Packaging, Labeling, Hardening and Shipping. In: Ice Cream". SpringerLink: 225–252 – via SpringerLink.

- ↑ Goff, H. Douglas (2013). Ice Cream. New York: Springer. pp. 225–252. ISBN 978-1-4614-6095-4.

- ↑ 7.0 7.1 7.2 7.3 7.4 https://www.uoguelph.ca/foodscience/book/export/html/1749

- ↑ 8.0 8.1 8.2 8.3 http://www.milkfacts.info/Milk%20Processing/Ice%20Cream%20Production.htm

- ↑ Badr, Muayad. (2018). Isolation and Characterization of Bacteria Isolated from Ice Cream Samples in Hyderabad, India. Journal of Pure and Applied Microbiology. 12. 2275-2282. 10.22207/JPAM.12.4.68.

- ↑ 10.0 10.1 10.2 Pal, Mahendra & Tesfaye, Sihin & Zeweld, Sisay. (2012). Hygienic and Microbiological aspects of Ice Cream. 39. 42-43.