Course:FNH200/Projects/2020/Potato chip

Potato chips are crispy, thinly sliced potatoes that have been deep fried or baked. They come with many different types of cut which includes straight, grooved, crinkled, or flat. Besides this variety in shape, there are also a wide range of flavors/seasonings available from many different brands. The traditional seasoning is simply salted, while other varieties that have been developed are manufactured using flavorings and ingredients like natural flavorings (e.g. herbs), artificial flavors, and additives.

Potato chips currently represent one of the world's most popular snack foods.[1] They are commonly served as a snack, side dish, or appetizer. The basic chips are cooked and salted. From its accidental birth in 1853, the potato chips market has evolved with time and currently represents a multi-billion dollar market.[1] Owing to their easy affordability and cheaper price even for the premium products, potato chips are popular among all age groups.[1] Currently, the growing young population (below 15 years) represents a key segment for the potato chips market.[1] Major factors driving the global demand of potato chips are growing urbanization, rise in disposable incomes and rapidly changing lifestyles.[1] The global potato chips market has grown at a CAGR[2] (i.e., compound annual growth rate) of around 4% during 2010-2017 and reached a market value worth US$ 28 billion.[1]

History

In the spring of 1853, at the Moon Lake Hotel, a customer thought that the French fries made by chef George Crum were too thick and he did not like it, so he refused to pay. George made French fires thinner, but it couldn't satisfy the customer either. George decided to meak the guest embarrassed, so he made the French fries so thin that couldn't be eaten with a fork. However, the customer liked the pale yellow, paper-thin potato chips very much. Other guests also asked George to make these potato chips for them. Since then, Saratoga potato chips appeared on the menu and became a specialty food.[3]

Soon, this potato chip was packaged and sold. At the beginning, it was only sold locally, and it immediately became popular throughout New England. Finally, George opened his own restaurant, and the biggest feature of the restaurant was potato chips. At that time, potatoes were peeled and sliced by hand. In the 1920s, the invention of the potato peeler turned potato chips from small-scale production into the most sold snack. Since the invention of the potato peeler in the 1920s, potato chips have become popular. In 1908, Leominster Potato Chips (later changed name to Tri-Sum) was the first potato chips manufacturer in America.[4]

Harvest and Storage

Since the 1950’s when the first bag of potato chips was sold to the market, potatoes were harvested for chipping by their dry tuber matter and light-colored content.[5] Potatoes with light-colored content is best grown and harvested at low temperatures, between 16 to 27 degrees Celsius. Machines that allow mass harvesting, which physically dig up the crop to collect the potatoes, enable the potatoes to maintain the tuber, dry content that makes the best chip.[6] These harvesting factors allow producers to grow the optimal potatoes for chipping purposes which can be sent to storage or the consumer market.

Storage of potatoes depends on two major criteria for any producer, climatic conditions and market influence.[5] Both of these factors affect potato storage and it’s management. When potatoes are harvested, they require specific atmospheric conditions to ensure that the quality and volume are optimized. Potatoes require a dry and low temperature atmosphere to dry out and delay any decay of the product.[5] Depending on the producers area, ventilation, heating, or cooling would be needed to provide these certain atmospheric conditions that allow potatoes to be stored and eventually sold to market.

Manufacturing Process

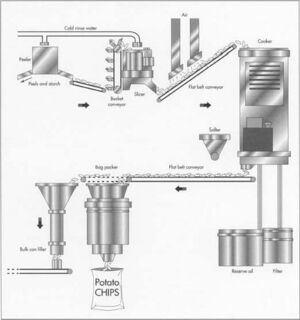

Washing and peeling

Washing and peeling is the first step of the manufacturing process of potato chips. Due to the large amount of potatoes, the peeling process is carried out by using an automatic machine instead of the potatoes being peeled manually. The machine contains "silicon carbide coated plate which rotates on a shaft attached with the motor".[7] The plate surface present in the machine is wavy which helps to peel the potatoes in an upward and downward motion. The skin of the potato comes in contact with the silicon carbide plate which helps to erode the skin and the non stop water supply helps with washing the skin off the potatoes. The peeled potatoes are finally collected in a tank filled with water so there is no carbide debris on the potatoes.[7]

Slicing

Once the potatoes are peeled, the rotary die cutting method is used because of how highly accurate and cost effective this method is. The method causes the rotator to rotates which pushes the potatoes away from the centre because of "centrifugal force".[7] Once they are in the centre, they come in contact with the blades where the potatoes are sliced into round pieces. It is important to note that the shape of the chip depends on the blade that was used.

Washing and drying

Now that the chips are sliced, they are collected in a tank filled with water where the chips remain inside of it in order to reduce the chances of them turning black which is due to oxidation. Potassium aluminum sulfate is used in the water to purify and provide the whiteness colour to the chips. When the chips are ready to be dried, they are removed from the tank filled with water and placed in dryer where they are rotated. The chips don't need to be fully dried.[7]

Frying

The second last process is where the chips get fried in a large pan filled with oil. The pan is lined with a perforated plate and is shaped as a rectangle and is sized 1800 mm x 900 mm x 300 mm. The pan is filled with vegetable oil and there is a pump to regulate the required amount of oil. As well, the oil is fixed at a temperature of 195 degrees Celsius which is the necessary frying temperature. Any temperature higher than this will cause the chips to burn.[7]

Seasoning

The final process before the potato chips are packaged into their bags is to be seasoned. This step is relatively simple and straight forward as the chips that just left the cooker for frying are transferred through a flat conveyor belt and into a drum filled with the desired seasoning powder.[8] The drum then shakes to allow the seasoning powder to reach every slice of the chips and to ensure the seasoning powder is being distributed evenly. Once the chips leave the drum, they are then transferred on a conveyor belt for cooling and to drain off excess oil. Finally, an optical sorter sorts out any burnt slices and removes them away from the conveyor belt, preparing it for the packaging stage.[8]

Packaging

Packaging materials

Before the invention of sealed packaging, potato chips were stored in large buckets or cans. In 1926, Laura Scudder invented a bag that heats two waxed papers together, and since then created a sealed package and preserved the freshness of potato chips until they are opened. The first plastic bags were introduced in the snack market in 1958, which were made of laminated plastic layers and aluminum to prevent air and light from entering and extend the shelf life of the product.[9] Today, a typical potato chip bag is composed of Biaxially Oriented Polypropylene (BOPP) on the inside, low-density polyethylene (LDPE) in the middle, another middle layer of BOPP, and an outer layer of Surlyn, a thermoplastic resin. Each layer has its specific function. BOPP is a moisture barrier that keeps moisture away from chips, and resistant to oils and grease. LDPE keeps vegetable oil inside, and both LDPE and Surlyn are strong but can be easily open.[10]

Modified atmosphere packaging

The reaction of oxygen with fats leads to the development of rancidity in vegetable oils products and in deep-fried foods such as potato chips, which is known as oxidative rancidity.[11] Once the food package is opened and exposed to the air, the contents exposed to oxygen will deteriorate. Thus, modified atmosphere packaging (MAP) is used to extend the shelf life of potato chips. The packaging bag is filled with nearly 100% nitrogen. To eliminate oxygen, nitrogen is repeatedly injected and removed from food packaging. The oxygen content can decrease to 3% or less in this process. Finally, the shelf life for consumers is extended.[12]

Health Concerns

Potato chips are commonly labelled as “unhealthy” for a number of reasons related to the way in which they are made, and the chemical reactions that occur as a result.

Acrylamide

Potentially carcinogenic chemical that forms naturally in certain starchy foods under high-temperature conditions. Such conditions including: deep-frying, roasting, and high-temperature treatments during food processing. The chemical production of acrylamide is the result of a reaction between the amino acid Asparagine and reducing sugars via the Maillard Reaction.[13] Several alternative cooking methods have risen to popularity over the years including baked or kettle-cooked chips. Despite the difference in texture and preparation, kettle-cooked chips are still cooked in oil and so contain very similar fat content when compared to the traditional, deep-fried variety. On the other hand, baked chips contain significantly less fat, with a bag of Lay’s Baked Original chips containing 3.5g fat compared to 10.5g in the classic version.[14] Several companies also offer varieties of their chips with reduced sodium and/or fat (e.g., Lay’s Lightly Salted). According to a study performed by Naruszewicz et al. in which 14 women ate 160g of potato chips every day for 4 weeks, each subject was found to have substantially raised levels of acrylamide in their bloodstream.[15] Subjects were found to develop into a proinflammatory state, in which the body’s cytokines actively progress any degenerative diseases that may be present in the body.[15] The proinflammatory state increases susceptibility to atherosclerosis, which is the clogging of arteries with plaque composed of cholesterol and lipids.[15]

Calories

One serving of Lay’s Classic Potato Chips - approximately 15 chips, contains 160 calories.[14] As with any foods, potato chips should not be eaten in excess as to avoid obesity/weight gain. Such issues arise when consumers eat a high quantity of potato chips on a consistent basis.

Fat

Saturated fat is prevalent in the majority of potato chips, and increases low-density lipoprotein (LDL) cholesterol (often referred to as “bad” cholesterol) in the body. High levels of LDL cholesterol in one’s body increases the risk of stroke and heart disease, therefore it is best to limit the consumption of foods high in saturated fat. Foods high in saturated fats include: dairy products, fried/baked goods, fatty meats, coconut and palm oils. Of all the fats, trans fat is considered the most unhealthy because it not only raises your LDL cholesterol, but also decreases your high-density lipoprotein (HDL), which is considered the “good” cholesterol because it transports excess cholesterol to the liver as waste to be excreted.[16] Trans fat is naturally found in animal products, as well as artificially produced as a result of hydrogenation of liquid oil into a solid form.[16] Margarine is a prime example as a product of hydrogenated oils, as the hydrogen gas molecules alter the degree of saturation, and thus, the melting range of the fat.[17] This induces the change from liquid to solid or semi-solid form.

Sodium

The average person should consume between 1500-2300mg of sodium per day.[18] However, it is estimated that the average Canadian consumes approximately 2760mg of sodium, which puts the average person at risk for high blood pressure.[18] High sodium intake is correlated with high blood pressure. In the United States, approximately one in every three Americans are expected to be diagnosed with High Blood Pressure (HBP) in their lifetime.[19] This is largely due to the high consumption of fast food in the U.S. On the other hand, a mere 17.7% of Canadians over the age of 12 were reportedly diagnosed with HBP in their lifetime.[20] High blood pressure may lead to symptoms of cardiovascular disease and stroke.

Collectively, the high caloric, fat, and sodium content as well as the presence of acrylamide in potato chips makes it an unhealthy snack for regular consumption. Apart from its excess of unhealthy traits, potato chips also pose a lack of vitamins and nutrients. As such, potato chips should not be consumed as a primary source of carbohydrates. However, occasional indulgence in small portions will not have any notably harmful effects on the average person’s overall health.

Regulations in Canada

Snack food products such as potato chips sold in Canada are subject to the provisions of the Safe Food for Canadians Act (SFCA) and the Safe Food for Canadians Regulations (SFCR), as well as those of the Food and Drugs Act (FDA) and the Food and Drugs Regulations (FDR).[21] When sold intraprovincially, snack foods are subject to the labelling requirements under the FDA and FDR, as well as specific requirements of the SFCA and the SFCR that apply to prepackaged foods sold in Canada, regardless of the level of trade.[21] Provincial regulations may also have labelling requirements that apply when these products are sold within that province.[21] Most snack foods are "unstandardized foods", meaning that no standard for composition is provided for them in the FDR.[21]

Labelling requirements for snack food products

Common name

- The common name "potato crisps" (the British term for "potato chips") is an acceptable alternative common name for "potato chips" on Canadian labels.[22] In French, the terms "croustilles" and "chips" are both acceptable.[22]

- Potato chips flavoured with acetic acid rather than vinegar must not be described as "salt and vinegar".[22] They may be described as "salt and vinegar flavoured potato chips", "salt and simulated vinegar potato chips", "salt and imitation vinegar potato chips" or "salt and artificial vinegar potato chips".[22] In the list of ingredients, the ingredient name "acetic acid" should be used, not "simulated vinegar flavour".[22] This decision is consistent with others taken regarding the claim "flavoured".[22]

Nutrition labelling

- Snack food products are often prepackaged in very small packages.[23] When the label of a prepackaged product has an available display surface of less than 15 cm², it is always exempt from displaying a Nutrition Facts table, even when it contains aspartame, neotame, sucralose or acesulfame-potassium.[23]

Comparative nutrient content claims

- Comparative nutrient content claims are those that compare the nutritional properties of two or more foods.[24] The major categories of comparative nutrient content claims are: reduced, lower, more, light in energy or fat (e.g. "33% less sodium per x serving than our regular potato chips").[24]

Interpretation of nutrient content claims

- Snack foods such as potato chips are other foods, which means the category of food to which belong foods that are not part of any food group (milk products and milk product alternatives; meat, poultry, fish and alternatives; bread and grain products; and vegetables and fruit).[25]

External Links

Oil-free potato chips produced by microwave multi flash drying

Potato Chips Market Growth, Trends, and Forecast (2020 - 2025)

How to Make Homestyle Potato Chips

Potential Exam Question

The development of rancidity in deep-fried foods such as potato chips is due to reaction of oxygen with fats, particularly those with high unsaturated fatty acid content. This is known as ___(i)___ rancidity. Therefore, to extend shelf life of potato chips, potato chip companies usually prepackage them in a ___(ii)___ Atmosphere Packaging, filled with nearly 100% ___(iii)___.

A. (i) Oxidative; (ii) Modified; (iii) Nitrogen

B. (i) Oxidative; (ii) Controlled; (iii) Nitrogen

C. (i) Lipolytic; (ii) Controlled; (iii) Carbon dioxide

D. (i) Lipolytic; (ii) Modified; (iii) Carbon dioxide

Answer: A

This question explores the concepts we learned in Lesson 5 and Lesson 7 thus is relevant and applicable as a final exam question. Furthermore, the question is pretty challenging in a sense that the student have to understand concepts instead of logically guessing.

References

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 IMARC Group (2017). Potato Chips Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2018-2023.

- ↑ Wayman, Rick (September 24, 2019). "Compound Annual Growth Rate: What You Should Know". Investopedia.

- ↑ "Who Invented Potato Chips?". WONDEROPOLIS.

- ↑ Harmon, John E. ""Potato Chips." Atlas of Popular Culture in the Northeastern United States".

- ↑ 5.0 5.1 5.2 Olsen, N. (2014). Potato storage management: A global perspective. Potato Research, 57(3-4), 331-333. doi:http://dx.doi.org.ezproxy.library.ubc.ca/10.1007/s11540-015-9283-7

- ↑ Busse, James (November 2018). "Transient heat stress during tuber development alters post‐harvest carbohydrate composition and decreases processing quality of chipping potatoes". Wiley Online Library. 99(5).

- ↑ 7.0 7.1 7.2 7.3 7.4 Goyal, Bhupesh; Goyal, Pravin. "Manufacturing of Potato chip and its Quality Improvement" (PDF).

- ↑ 8.0 8.1 "Potato Chip". Made How. Retrieved 11 August 2020.

- ↑ Danielle, Ohl (June 12, 2019). "Packaging History 101: The evolution of snack packaging". Viking Masek.

- ↑ Polymer Solutions News Team (September 21, 2015). "Packaging the Chip Challenge Flavors". Polymer Solutions Incorporated.

- ↑ Chan, Judy (July 2020). ""Lesson 5: Rational for Food Preservation." UBC: FNH 200(942), Exploring Our Food. Canvas". Retrieved August 7, 2020.

- ↑ Schneider, Mark D. (September 2016). "The Atmosphere Inside a Bag of Potato Chips" (PDF). The Atmospheric Reservoir.

- ↑ Health Canada (November 25, 2019). "Acrylamide and Food". Government of Canada.

- ↑ 14.0 14.1 "Nutrition Facts". Frito Lay Canada. 2020.

- ↑ 15.0 15.1 15.2 Naruszewicz, M. (2009). ASSOCIATIONS OF CHRONIC INTAKE OF POTATO CHIPS AND CORONARY ARTERY DISEASE RISK FACTORS. A POSSIBLE ROLE OF ACRYLAMIDE. Atherosclerosis Supplements, 10(2). doi:10.1016/s1567-5688(09)70646-4

- ↑ 16.0 16.1 "Trans Fats". American Heart Association. 2020.

- ↑ "Hydrogenation". Wikipedia. 2020.

- ↑ 18.0 18.1 Health Canada (August 14, 2018). "Sodium Intake of Canadians in 2017". Government of Canada.

- ↑ Cox, Lauren (May 30, 2013). "Why Is Too Much Salt Bad for You?". Live Science.

- ↑ Statistics Canada (November 27, 2015). "High Blood Pressure".

- ↑ 21.0 21.1 21.2 21.3 Canadian Food Inspection Agency (January 15, 2019). "Overview". Government of Canada.

- ↑ 22.0 22.1 22.2 22.3 22.4 22.5 Canadian Food Inspection Agency (March 24, 2014). "Snack Foods". Government of Canada.

- ↑ 23.0 23.1 Canadian Food Inspection Agency (January 15, 2019). "Nutrition labelling". Government of Canada.

- ↑ 24.0 24.1 Canadian Food Inspection Agency (May 11, 2018). "Comparative nutrient content claims". Government of Canada.

- ↑ Justice Laws Website (July 1, 2020). "Food and Drug Regulations". Government of Canada.