Course:FNH200/2012w Team16 Cheetos

Cheetos: Deliciously Cheesy...but how?

Cheetos have been around since 1948 [1]. The trademark texture, flavour, and shape have led to its worldwide success. Now an expanded brand to include 21 different types of Cheetos including the traditional puffed shape, Cheetos has become a household name [1]. The inclusion of their mascot Chester Cheetah makes them a recognizable brand, but what makes this product so popular? How do they make their trademark puff shape? How is the cheesy flavouring made and what is included? How does this product maintain its shelf life? And most importantly, is it nutritious? These are the questions that we aim to explore in this section, and by the end you will be able to answer these questions to learn more about this mischievously cheesy product!

Introduction

What are Cheetos?

Commonly known in North America as Cheetos or Crunchies, cheese puffs are a puffed corn snack that is coated with cheese and/or flavored powders. Commercially packaged around the world, this product is branded by manufacturing companies with many different names such as Cheetos, Cheese Curls, Curl, Twisties, Cheezies, Chee Wees and Cheez doodles. They can be found in local grocery and corner stores and are enjoyed by many![2]

History

The history of cheese puffs dates to the 1930’s in the United States of America. There are two accounts or claims to who actually invented them.[3] The first is Edward Wilson and/or Clarence J. Schwebke of a company called Flakall Corporation. Flakall was a producer of animal feed, which consisted of deep fried and salted corn. They decided to add cheese to the corn puffs and applied for a patent of the product in 1939 under the name “Korn Kurls.” They became a common snack in 1946 by the Adams Corporation. The Adams Corporation was formed by the Flakell sons and was later bought by what we know today as Beatrice Foods.[2]

The other account of the cheese puffs is that is was invented before 1936 in Louisiana, New Orleans by the Elmer Candy Corporations. The sales manager Morel M. Elmer, Sr. decided to call his product “CheeWees” after holding a contest in New Orleans to name his product. Elmer’s Fine Foods still uses this name today and still produces their CheeWees!

Cheetos were invented shortly after in 1948 and the Puffs came later in 1971.[4] The company that started making the brand Cheetos was Charles Elmer Doolin. Doolin worked for Fritos in Texas and he started off his company by making and selling corn chips out of his Model T. Ford. Doolin could not keep up with the demand of the product so he partnered with businessman Herman W. Lay. Distribution of corn chips came nation wide and success flourished for both Doolin and Lay, Forming H.W. Lay & Company. They became one of the largest snack food companies even today accounting for 59% of the snack industry products. In 1961, they became the chip company we know and love today, “Frito-Lay, Inc”. [5]

The snack is still popular today with many companies producing their own version, ranging from Puff’n corn, to Crunchies and Cheetos. The easy recipe lends to endless possibilities for this tasty treat![2]

Ingredients & Function

Enriched cornmeal and seasoning are the 2 main components that make up a bag of delicious Cheetos.

Ingredients of Enriched Cornmeal

Cornmeal is made by grinding dried maize or corn into coarse flour. [6] It is the primary ingredient used to make cheese puffs as the ingredients on the label are listed by descending proportion of weight.[7]

Iron,Niacin,Thiamine, Riboflavin and Folic acid are vitamins and minerals which are added to the cornmeal to enrich the nutrient content. [8] Food fortification plays an important role in ensuring the health of the consumers, as the added micronutrients can replace the nutrients that are lost during the manufacturing process of the cornmeal flour.[9] Food fortification benefits consumers' overall health by protecting them from nutritional deficiencies.[9]

Ingredients of Seasoning

Whey is a by-product from cheese production.[10] It acts as a binder to hold the various components of the seasoning together and adds thickness and texture to the cheese coating. [10]

Cheddar cheese is a semi-hard cheese that ranges from white to yellow in colour and it is primarily added to food products for flavor.[10] Since cheddar cheese is a component of the cheese coating, Cheetos has a rich cheese flavor.

Vegetable oil is high in unsaturated fat. [11] Since oil is a carrier of aroma constituents, it is responsible for the characteristic aroma when one opens a bag of Cheetos.[11] Vegetable oil also contributes to the rich and creamy taste of the cheese coating, which gives consumers a feeling of satiety.[11]

Corn maltodextrin is a carbohydrate based fat substitute that is easily digested and absorbed by the body. [12] It contributes to the “fatty mouthfeel” of the Cheetos’ seasoning, while it only contains 4 Calories per gram.[12]

Salt is a mineral composed of sodium and chlorine and it is a seasoning which imparts a salty flavor in Cheetos and has a preservative function.[8]

Monosodium Glutamate is a flavor enhancer, which is used to bring out the savory taste of Cheetos.[13] Monosodium glutamate is the sodium salt of glutamic acid.[14] It is produced through a fermentation process and the product has a white crystalline structure.[14] According to Frito-lay, a small amount of monosodium glutamate is added in the seasoning to reduce the amount of salt needed by 20 to 40 percent. [13]

Natural and Artificial Flavours enhances the flavor of the Cheetos. Since Frito Lay has its own secret recipe for the production of Cheetos, the company is not required to list the ingredients that make up the natural and artificial flavors.[8]

Lactic acid is an approved food additive in Canada.[15] It is commercially produced by bacterial fermentation with carbohydrates.[16] Lactic acid acts as a pH adjusting agent, which aids in the preservation in the production of Cheetos.[15]

Citric acid is a versatile food additive that is permitted for use in Canada.[15] It is found in high concentrations in many citrus fruits and can be produced by the fermentation of cane sugar with the fungus Aspergillus niger.[16] Citric acid does not only impart a sharp tasting flavor to Cheetos, but it also functions as an antioxidant; citric acid slows the oxidation of fats and oil in the food product, so the freshness of a pack of Cheetos can be retained for a longer time.[16]

Sunset yellow FCF, commonly known as yellow number 6, is an approved food additive in Canada which gives the orange-yellow colour in food.[17] Sunset yellow FCF is used to enhance the characteristic orange colour of the cheese coating, thus giving a pleasing appearance of the Cheetos. [17]

Processing

Deep Frying

The processing of Cheetos is similar to that of potato chips, they are first extruded then either baked or deep fried to create the shape that is characteristic of Cheetos. The initial process begins with a mixture of cornmeal and water [18]. The cornmeal that is chosen must have a low moisture content because an abundance of moisture can lead to a soggy product [18]. After the cornmeal is chosen, water is poured on top of the cornmeal resulting in a gluten formation. This gelatinized starch is then immediately extruded when a desired consistency of the mixture is achieved [18]. During the extrusion process, the cornmeal mixture is exposed to heat, moisture and pressure, which further gelatinizes the mixture. Not only does the hot temperature, in the form of steam, cook the product, it creates the shape as well [19]. The mixture is forced through a narrow tunnel known as a die, which shapes the product. The escaping steam within the die causes the product to “puff” while also slightly curling the product [20]. The product puffs because the cornmeal mixture is in contact with the hot air which causes the steam to expand resulting in a “puffed” product [19]. Similar products processed by extrusion are breakfast cereals, confections, infant foods, textured proteins and other snack products.

Immediately after the mixture is extruded, a rotating knife cuts the puff pieces into their desired length [18]. The product is then deep fried in vegetable oil to further reduce the moisture content [20]. The high temperature of hot oil causes the water to evaporate. However, the pieces accumulate oil from the deep fryer therefore the dried puff pieces have a low water content and a high oil content [19]. This contributes to the crunchiness of the product. In other cases, after the extrusion process the mixture can be baked instead of deep fried which results in a different fat content [18].Instead of being put in vegetable oil the puff pieces are put on a conveyor belt into a large oven or a dryer. The oven is hot enough to remove the moisture of the pieces, which gives the emerging pieces their crispiness [18]. Unlike deep frying, the products do not darken because they do not retain the same level of fat. After this process, the puff pieces are covered with a cheesy coating.

Cheesy Coating

Now that the puff pieces have dried, the deliciously cheesy flavor is added. There are two methods used for applying the flavor to the dry cornmeal crisps. In the first method, the extruded corn curls are sprayed with oil (commonly vegetable, coconut, or cottonseed oil) and then dusted with the dry flavoring, color and seasoning [18] It is important to note that the oil enables the cheesy powder and seasoning to stick to the cheese curl, making the bland corn puffs palatable [6]. During the second method, all of the oils, flavoring, and seasoning are combined in a tank, and are sprayed on the cheese curls as they tumble in a revolving drum [18]. Usually, only one type of oil is sprayed on each batch. After the flavoring has been applied by either of the above methods, the cheesy Cheetos must now go on the conveyor belt and dry before they are packaged.

Although the exact method and recipe for Cheetos flavoring could not be found, it is known that cheese puffs and Cheetos follow a similar processing method. Firstly, there is food coloring to give these puffs their characteristic orange color. For the delicious cheesy flavor, cheddar cheese powder is used in addition to artificial cheese flavoring. Cheddar cheese powder is made by dehydrating regular cheese, in other words, it is what remains once all of the moisture of regular cheddar cheese is removed [18] Other ingredients include whey powder (which binds the various components of seasoning together), salt and other spices to be specified by the manufacturer. [6].

Packaging

Weighing & Heat Sealing

Once the Cheetos have completed processing, they are placed onto a vibrating conveyor belt and are cooled to room temperature.[20] The dried Cheetos are collected into a large funnel and through what is called a weighing machine.[20] The weighing machine measures the correct amount of Cheetos that fall out of the sieve and into the bag. The cheese puffs bags, like many chip bags, are made out of polypropylene and other materials that are designed to keep the product crisp and resist moisture. [21] Heat is used to seal the top of the bag and the bags are placed into large boxes to be shipped to distributors.[20]

Science Behind the Bag

Proper packaging is an important factor in maintaining the quality of the food product. Specifically to Cheetos, the cheese puff must remain flavorful and crispy rather than stale and soggy. To prevent the latter from happening, the bag must be made and sealed in a way to prevent any gas or moisture from entering or leaving the package [22].

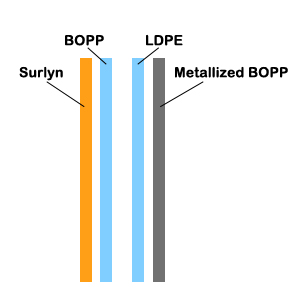

Potato chips and Cheetos bags are made from polypropylene and additional materials. The bag must be opaque because light entering the package will allow oxidation reactions to occur and the food product inside could potentially become rancid [23]. Cheetos bags are also flexible with multiple layers. This is both for protection against rough handling and storage and also each as a purpose [23]. There is a layer of Surlyn for the labeling of the nutrition information, manufacture information, the logo and any additional marketing materials that could be added onto the packaging [22]. Surlyn is a material that is tough, repels oils and handles abrasion [22]. Another layer is the LDPE, this lightweight layer is used for its chemical resistance, moisture protection and sealing properties [22]. BOPP is a gas barrier and when metalized, offers light protection [22].

The way the bags are sealed is important for maintaining the quality of the Cheetos too. Bags are heat sealed at both ends and in the sides to maintain a moisture and light barrier [23]. The temperature the bags are treated to is tested extensively to create a seal that is both effective but easy enough to open for the consumer [20]. Packaging may also include the introduction of nitrogen and carbon dioxide into the bag through modified atmosphere packaging. Nitrogen maintains anaerobic conditions inside and prevents the oxidation of oils and fats that cause rancidity [24]. Carbon dioxide alternatively has anti-microbial properties and inhibits the growth of spoilage microorganisms [24]. Combining the modified atmosphere packaging with the protective bag design, bags of Cheetos will have a longer shelf life and remain deliciously cheesy and fresh.

Taste/Quality Control

To ensure the quality of every Cheetos bag is at its best, several steps and actions are taken. First of all, each production plant needs to be audited and must comply with certain criteria in order to be certified by different external agencies [25]. These agencies use the Hazard Analysis and Critical Control Points (HACCP) to make sure the production occurs in a Food Safety Environment. [25] Moreover, each plant used for the production of Cheetos is certified ISO 14000, which means the manufacturing methods of the products are environmentally safe. [25]

Hygiene is also very important for the manufacturers of Cheetos. Indeed, all the equipment, processes and facilities used during the production must comply with high hygiene and sanitation regulations and standards. [25] Also, the packaging of the final product must take place under strictly controlled hygiene conditions to ensure there is no contamination during the process. [25]

Cheetos also ensures its quality by evaluating its suppliers and subjecting the raw materials to strict quality inspection at their arrival to the processing plant.[25] These quality control practices warrant that only the best quality raw materials, including flavours and spices, are being used in the production of Cheetos. [25] Furthermore, during the confection of the snack, samples are pulled out of the cooking line every half hour and are sent to an in-house lab to be analyzed [20]. The samples are analyzed regarding their chemical composition in order to determine if the nutrient density and the nutrient content meet the required standards[20]. In addition, every four hours, 4 panelists are required to taste and inspect the product[20]. The panel then compares the product with a Cheetos sample of ideal quality, which has been sent from the Frito Lay headquarter itself [20].

Nutrition

Consumed once in awhile, Cheetos are a deliciously cheesy snack. However, if they are consumed on a regular basis, Cheetos are not a healthy choice. Indeed, even if they do not contain any Trans-fat, Cheetos remain high in fats and in sodium, which are 2 major health concerns. In fact, a serving (1 oz, approximately 27 pieces) of Cheetos accounts for 28% of your recommended dietary allowance of fat and for 20% of your recommended dietary allowance of sodium. One should pay particular attention to their sodium intake because the majority of Canadians consume twice as much as the recommended daily value. Moreover, large sodium intake leads to increased risks of high blood pressure and hence, increased risk of coronary heart disease and strokes [26]. Also, their puffy texture often misleads the consumer to think that Cheetos do not contain high caloric value. In reality, Cheetos are quite caloric and do not provide a lot of nutrients [27]. They are therefore considered to be an energy-dense food, and should only be consumed occasionally.[27]

Question

Cheetos:

are made of ______(i)_______ and water,

are processed through ____(ii)___,

are sprayed with___(iii)____ in order to make the cheesy coating stick,

are then packaged using ___(iv)____ in order to ___(v)____.

- a) (i) corn meal, (ii) baking/deep frying, (iii) monosodium glutamate, (iv) modified atmosphere packaging, (v) increase shelf life

- b) (i) rice flour, (ii), sun drying, (iii) oil, (iv) tetra pack, (v) decrease shelf life

- c) (i) corn meal, (ii), baking/ deep frying, (iii) oil , (iv) modified atmosphere packaging, (v) increase shelf life

- d) (i) rice flour, (ii), baking/ deep frying, (iii) water, (iv) modified atmosphere packaging, (v) increase consumer appeal

Other Videos

Supplementary videos to further show how Cheetos Processing is done.

1:15-2:01 - This is a video from BBC One on how to create Cheesy Puffs. Although it does not look like the classic curved shape of Cheetos, the process is similar. By using a corn maize mixture and treating it to heat, steam and moisture, we are able to make "poofed up" snacks like Cheetos. The device that is used in this video is called the extruder.

This is a video from "How it's Made" discussing the production of Cheese Puffs. 3:16 shows a good representation of how the Cheetos exit the extruder. 3:25 shows how the revolving drum looks like when the Cheetos are mixed with the oil, cheese and flavoring powders. 4:06-4:35 shows how potato chips are packaged into bags and how the bags are heat sealed. Cheetos are packaged in a similar way but the additional step with modified atmospheric packaging is applied before heat sealing.

References

- ↑ 1.0 1.1 Wikipedia. (2012). Cheetos. Retrieved from http://en.wikipedia.org/wiki/Cheetos

- ↑ 2.0 2.1 2.2 Wikipedia. (2013). Cheese puff. Retrieved from http://en.wikipedia.org/wiki/Cheese_puffs

- ↑ Culinary Encyclopedia. (2013). Cheese Puff. Retrieved from http://www.ifood.tv/network/cheese_puff

- ↑ Wiki Answers. (2013). "Were Puffy Cheetos or Cunchy Cheetos Invented First?". Retrieved from http://wiki.answers.com/Q/Were_puffy_Cheetos

- ↑ Frito-Lay. (2013). How it All Began. Retrieved from http://www.fritolay.com/about-us/history.html

- ↑ 6.0 6.1 6.2 Wiesen, G. (2013).What is Cornmeal. Retrieved from http://www.wisegeek.com/what-is-cornmeal.htm Cite error: Invalid

<ref>tag; name "Wisegeek" defined multiple times with different content - ↑ Chan, J. (2013).Food Standards, Regulations and Guides-Food Additives. Retrieved from http://wiki.ubc.ca/Course:FNH200/Lesson_04

- ↑ 8.0 8.1 8.2 Leavitt, S. (2013).Chemicals in Cheetos. Retrieved from http://www.ehow.com/info_8448280_chemicals-cheetos.html

- ↑ 9.0 9.1 Health Canada. (2005).Information Sheet-Food Fortification in Canada- Current Practices. Retrieved from http://www.hc-sc.gc.ca/fn-an/nutrition/vitamin/fortification_factsheet1-fiche1-eng.php

- ↑ 10.0 10.1 10.2 Canadian Dairy Commission. (2011).Dairy Ingredient Profiles. Retrieved from http://www.milkingredients.ca/index-eng.php?id=170

- ↑ 11.0 11.1 11.2 Schneeman, B.O. (1986). Fats in the diet: Why and where?.Food Technology, 40(10), 115-120.

- ↑ 12.0 12.1 Chan, J. (2013).Fat and Sugar Substitutes-Sensory Preception of Foods. Retrieved from http://wiki.ubc.ca/Course:FNH200/Lesson_03

- ↑ 13.0 13.1 Frito Lay. (2013).Explaining Ingredients. Retrieved from http://www.fritolay.com/yourhealth/explaining-ingredients.html

- ↑ 14.0 14.1 European Food Information Council. (2002).The Facts on Monosodium Glutamate. Retrieved from http://www.eufic.org/article/en/artid/monosodium-glutamate/

- ↑ 15.0 15.1 15.2 Health Canada. (2006).Food additives permitted for use in Canada. Retrieved from http://www.hc-sc.gc.ca/fn-an/securit/addit/diction/dict_food-alim_add-eng.php

- ↑ 16.0 16.1 16.2 Food Additives and Ingredients Association. (2008).Acidulantsa. Retrieved from http://www.understandingfoodadditives.org/pages/Ch2p9-1.htm

- ↑ 17.0 17.1 Health Canada. (2012).List of Permitted Colouring Agents. Retrieved from http://www.hc-sc.gc.ca/fn-an/securit/addit/list/3-colour-color-eng.php

- ↑ 18.0 18.1 18.2 18.3 18.4 18.5 18.6 18.7 18.8 Bryk,N. (2011).Cheese Curl. Retrieved from http://www.madehow.com/Volume-5/Cheese-Curl.html#b

- ↑ 19.0 19.1 19.2 Chan,J. (2012).Dehydration as a Food Preservation Method. Retrieved from http://wiki.ubc.ca/Course:FNH200/Lesson_08

- ↑ 20.00 20.01 20.02 20.03 20.04 20.05 20.06 20.07 20.08 20.09 Koerner, B. (2010). Making Cheetos: It Ain’t Easy Being Cheesy. Wired. Retrieved from http://www.wired.com/magazine/2010/05/process_cheetos/

- ↑ Dow. (2013). Better Packaging: The Complexity of Chips. Retrieved from http://msdssearch.dow.com/PublishedLiteratureDOWCOM/dh_08a5/0901b803808a5479.pdf?filepath=news/pdfs/noreg/162-02714.pdf&fromPage=GetDoc

- ↑ 22.0 22.1 22.2 22.3 22.4 Faciszewski, M., Karwan, M., Kim, E., Thomas, C. (2000). Polymers in Food Packaging: With a Special Look at Potato Chips. Retrieved from http://www.eng.buffalo.edu/Courses/ce435/Food/PolymersProject.htm

- ↑ 23.0 23.1 23.2 Harris, M., Goates, W., Higgins, L., Van Natta, S. (1999). Food Packaging: A Learning Cycle of Activities. Retrieved from http://www.polymerambassadors.org/foods06.pdf

- ↑ 24.0 24.1 Orem, W. (2012). How Do Potato Chips Stay Fresh In The Bag? Retrieved from http://indianapublicmedia.org/amomentofscience/potato-chips-stay-fresh-bag

- ↑ 25.0 25.1 25.2 25.3 25.4 25.5 25.6 PepsiCo Inc. (2013). Cheetos PepsiCo. Retrieved from http://pepsicoindia.co.in/brands/Cheetos.html

- ↑ Nancy R. Cook (2008). Salt intake, blood pressure and clinical outcomes.Current Opinion in Nephrology and Hypertension. Retrieved from http://ovidsp.tx.ovid.com/sp-3.8.1a/ovidweb.cgi?QS2=434f4e1a73d37e8c1d085c12c2e0a0e49f135c3ea911d804af74858b7c7fceba538c690421ee8a6d87b12b85a1311cd0770ee2f872ac27f0af73180ab2581a5b6a667c6b1d1d55efddd883ad9a1b0523be6b3aeccc3d2c7c570563074570a0861f3b73754a6f493b53b34b108ea0e8cc94c86b00dc94172d42c7931e1f5b364967c0cf5644ce4781c7e487fdbb3230be0c9607a11c7018f6badb017cecfc719be2e29b6baa9071ea7d05caac0f8665c569f768c58d64fcc23f6793231aa6a627f8cfdfad44fd25af85bc9bfebaf0218f8557c4658fe29039115f47657a80db92e0cbb384c9427ddee528bf29e0607f6c2f08b35f5c24c2f3b4c0d017f3caed9f1cc4c4f1ae306e7e641a8f1d8e0cbb7c32ab491e2743feee12a9a6051aef1e29926cbbc04e18e8ba3add41165f9aaf0f2a19e2e3625b1e84a871daea7dd0d96912e93aaaeeb363accc88c77240110b429a6fb917c947dceee7e19dab6e5ac29cba099ae2724ef059fb9fa01bc1978a0b6010115b26eb241a68dfe277cfdc249aa60c37c47f7bf67bfcda5e1d96e332dd500e94422450a92cbea3e29a28401c718fd1152a0069f8b63580aa2c856562803a4adb2b14203f6d5e171a631839e6949c615059b351a2e0a7fd1075a1d48ff30b928a15f0b9cec706688e2dc8222a75363db5954da48504f730c1831de622ade5803990955dff4e8e36ce09415cd28f6a3f77c657f329db0eec015cd5bfa3b524f236e31aa4cfd4832ae9f3b427d0eae10289a2c6921c26e7636e19b562ae801fb3c01b5291c0eb9612152b136bfd63

- ↑ 27.0 27.1 Hammond, G. (2012). Nutrition concepts& controversies FNH 250 Lecture notes [Power point slides]. Retrieved from https://www.vista.ubc.ca/webct/urw/tp0.lc5116011/cobaltMainFrame.dowebct