Course:SPPH381B/Essay 2/Hazard Recognition-Alex

The Occupational Hygiene Paradigm to Problem Solving

The occupational hygiene paradigm involves three basic steps to hazard mitigation: recognition, evaluation, and control. This process is cyclical, involving yearly reviews and ongoing surveillance to continue improving workplace safety.

Recognition

Recognition of hazards involves understanding the workplace and anticipating the kinds of threats that may be present. For example, hazards may stem from the materials used or the processes involved in the work.

In order to recognize these hazards, there are various tools that can be employed: walkthroughs, documentation, literature sources, and communication. Walkthroughs simply involve going through the workplace, and looking for potential hazards. Documentation, such as first-aid reports, indicate which hazards have already caused accidents. However, this may not be comprehensive, as it requires complete employer transparency, and many minor accidents may have been omitted to avoid tedious paperwork. Literature sources are another tool that may reveal hazards that similar workplaces have encountered. Lastly, communication with both employees and management is key to recognizing hazards. For this, it is important that both parties express their concerns, as they may have differing views on what they consider to be hazards.

Prioritizing Risk

After the hazards are identified, they need to be prioritized so that they can be addressed in order of importance. One way of prioritizing hazards is to use the equation for risk:

Risk = Probability x Consequence x Exposure

Where each factor is ranked from one to four, with one being the mildest. For example, a worker at a gas station would be exposed to numerous hazards, including potential robbery or inhalation of gasoline fumes.

Risk (gasoline fumes) = possible (2) * significant (3) * continuous (4) = 24

Risk (robbery) = rare (1) * catastrophic (4) * continuous (4) = 16

While armed robbery could have catastrophic effects, the frequency is so rare that gasoline fumes are actually ranked as more risky as they are omnipresent at gas stations. For example, in one study of gasoline workers in Brazil, "over 60% of workers had experienced adverse symptoms related to benzene toxicity" [1]

Another way to calculate risk is to use a risk priority matrix, whereby risk is calculated by multiplying the likelihood of an event by the potential consequence.

Figure 1.1 Risk Priority Matrix

[2]

Evaluation

Following recognition, hazards are evaluated. The purpose of the evaluation is to assess hazards intensity, duration, frequency, as well as numbers exposed and population characteristics. These then aid in subsequent control of hazards.

One important step in evaluation is the classification of hazards, seen in the table below.

| Type | Length of Effect | Route of Entry |

| Chemical

Physical Biological Psychosocial Safety Ergonomic |

Chronic

Acute |

Inhalation

Ingestion Dermal absorption Direct ingestion |

There are several strategies involved in evaluation, including the examination of past medical records, sampling (both real-time and not), and models. In order to ensure consistency, standards were developed by NIOSH (The US National Institute for Occupational Safety and Hygiene [3]) and the EPA.

Control

Lastly, hazards are controlled in order to prevent injury, involving both short-term and long-term workplace plans.

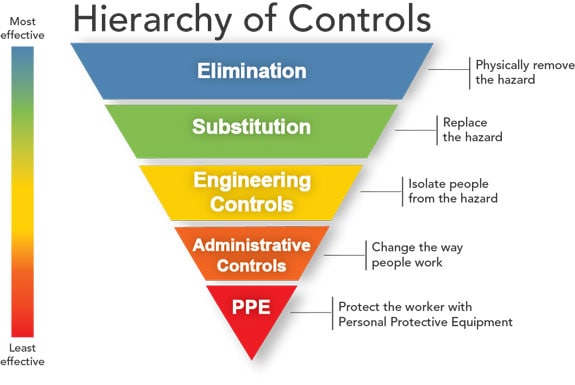

In order to implement effective controls for hazards, the hierarchy of controls is used:

[4]

[4]

While it is most effective to simply eliminate the hazard, it is not always possible to do so, and so controls from lower on the hierarchy of control pyramid are used when applicable. For example, it is not always possible to use engineering controls to eliminate noise or exposure to lead [5].

Since it is not practical to completely eliminate hazards, the principle of ALARA, or “As Low As Reasonably Achievable,” is used. ALARA not only includes health considerations, but also social, technical, and economic factors [6]. ALARA is often used in the context of carcinogens, where keeping exposures to a minimum would reduce toxicity effects as well as genotoxic damage to the human body [7].

References

- ↑ Sunisa,C., Pimpasaeng, C., Thapphasaraphong, S. (2015). Benzene Exposure at Gasoline Stations: Health Risk Assessment. Human and Ecological Risk Assessment: An International Journal. 21,8 (2213-2222)

- ↑ The University of Sydney. (2015). STEP 2 - ASSIGN PRIORITY FOR EACH HAZARD OR HAZARDOUS JOB. Retrieved from http://sydney.edu.au/whs/activities/prioritise.shtml

- ↑ Centre from Disease Control. (2017). The National Institute for Occupational Safety and Health (NIOSH). Retrieved from https://www.cdc.gov/niosh/.

- ↑ Centre from Disease Control. (2017). Hierarchy of Controls. Retrieved from https://www.cdc.gov/niosh/topics/hierarchy/

- ↑ Centre from Disease Control. (2017). Engineering Controls. Retrieved from https://www.cdc.gov/niosh/engcontrols/

- ↑ Nuclear Solutions Division. (1994). The ALARA Concept. Retrieved from http://www.iem-inc.com/information/radioactivity-basics/radiation-risks/the-alara-concept

- ↑ Neumann, H., & Neumann, H. (2009). Critical reviews in toxicology: Risk assessment of chemical carcinogens and thresholds Taylor & Francis. doi:10.1080/10408440902810329

.