Course:FNH200/2013w Team19 Milk

Milk

Introduction

Humans have been consuming milk for thousands of years. Of course, the product back then was much different from the product we have today. This article looks at Canadian fluid milk and sets out to answer several questions about the product. How far has milk come since we first began using it? How do we produce milk today? What are the standards and regulations that manufacturers and distributors abide by with today's product? What's so special about Canadian milk and how does it differ from American milk? How much milk do Canadians consume? What are the benefits of drinking milk? Are there any dangers associated with milk and, if so, how can we avoid them?

History

Humans have been drinking milk from animals such as sheep, goats, and cows for thousands of years. Cow's milk has been and still is an important part of Canadian's diets. European dairy cows were brought to North America in the early 1600s. A French microbiologist named Louis Pasteur developed the process of pasteurization in 1862, which has revolutionized the safety, storage and distribution of milk well beyond the farm.[1] The commercial pasteurization machine was later introduced, but it took many years of fighting for public health regulations and inspections before a safe milk supply was secured in Canada.[1] In 1927, a typhoid epidemic from contaminated milk affected more than 5000 people and caused 533 deaths in Montreal. The Canadian Public Health Association and the Canadian Medical Association pressed for compulsory pasteurization of milk ever since. [2] Later in the 1930s milk cans were replaced with large on-farm storage tanks, and plastic coated paper cartons were invented, which allowed for wider distribution of fresh milk.[1] Today, the processing of milk takes less than one day from beginning to end. All milk in Canada is required to be pasteurized and fortified with vitamin D to aid in calcium absorption, low fat milk is also fortified with vitamin A and contains many essential nutrients.[2]

Packaging

Overview

There are several materials used for milk packaging including: glass, recyclable plastic, plastic pouches, tetrahedrons, plastic bottles and gable top paperboard cartons. [3] We will look at the more common types of packaging available in Canada. These types are: glass bottles, plastic bottles, plastic pouches and gable top paperboard.

Glass

The traditional method for milk packaging is glass bottling.[3] The components of the glass are (in order of greatest quantity to least): quartz sand (silica and SiO), soda ash (NaCO3), limestone (CaCO3), and other minor components. [4] When extreme heat is applied (1500°C) this formula results in the production of soda-lime glass.[4] If the batch is to be made from recycled glass, broken pieces of glass are added to the mixture.[4] The pros of using glass are extensive. Glass does not allow for penetration of gas into the product, it does not react with the milk and cause detrimental results, glass can be reused and recycled, it allows consumers to see the product which provides sensory details of the milk and it is able to be heated to high temperatures without breakdown (as during sterilization).[4] However, glass does have some detriments. For example, the packaging is very heavy which makes transportation more costly.[4] Furthermore, glass can shatter due to impact or thermal shock.[4]

Plastic

Plastic packaging is most commonly manufactured using petroleum or natural gases.[4] In the case of plastic bottle production, certain types of plastic, called thermoplastics, are used.[4] This branch of plastics softens when heated which allows for specific shaping of the plastic that will be retained when cooled.[4] The benefits of plastic are numerous.[4] Plastic is light weight, fairly durable and chemically inert (cannot react with product).[4] Plastic packaging allows consumer to visibly see the contents.[4]

Plastic Bottles

Plastic bottles are the most common method for milk packaging. .[3] This method involves 2 L or 4 L bottles made from high density polyethylene.[3] This method is preferred because it is very easy to dispense the milk and the container can be closed after opening.[3] Furthermore, this type of packaging does not alter the flavour profile of the milk.[3] It is an exceptional barrier for water and water vapour.[3] The plastic bottles are quite strong and do not easily break upon impact.[3] They are also a cost-effective, and easy, method of packaging milk for the manufacturer.[3] One downside to the high density polyethylene bottles is that they are not a formidable oxygen barrier.[3] However, this is not a major issue since this property is not an important one for the quick distribution time involved with milk products.[3] The filling process with the plastic bottle is rapid; up to 100 bottles can be filled per minute using either a regular in-line or rotary turret liquid gravity filling machine.[3] The bottle is sealed with a friction fit injection molded polypropylene cap.[3] The cap normally has a seal that shows if the product has been tampered with.[3]

Plastic Pouches

The plastic pouch method has been used for several decades.[3] The pouch is made of a thin polyethylene film that is flexible.[3] The plastic pouch is very common in the food service industry.[3] It is also very popular in Eastern Canada, but rarely seen in

Western Canada.[5] The process is simple: form (the bag), fill and seal.[3] It is mediated by a specially designed machine that is specific to liquid filling.[3]

The bag can then be placed into a box made from corrugated fiberboard[3] or into a larger plastic bag. The former is referred to as bag-in-box packaging. An aseptic dispenser can be added to the packaging.[3] In order to impair the growth of microorganisms, the bag is sterilized by ionizing radiation prior to filling.[3] For consumer use, the pouch is placed into a pitcher.[3] The pouch is then cut and can be poured using the pitcher.[3] This method is very efficient in terms of the milk product and the packaging materials.[3]

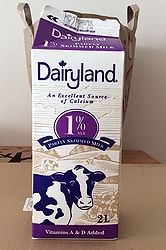

Gable Top Paperboard Carton

The gable top paperboard carton is available in sizes up to 2 L.[3] The carton is constructed from liquid resistant virgin solid bleached sulfate paperboard.[3] The outer layer of the carton is made from low density polyethylene.[3] This outer layer functions to increase resistance to liquid and water vapour.[3] It also enables the product to withstand a wider temperature range during the sealing process.[3] The milk manufacturer receives the cartons in a knocked down form.[3] They are quickly formed into the cartons using a special piece of machinery.[3] This machine opens the knocked down cartons, places them onto a mandrel and flattens the bottoms of the containers via heat sealing.[3] The carton is then taken off the mandrel and placed upright. The filling process can then occur using a gravity-type filler.[3] The top of the carton is then closed with a heat seal using pressure and conduction heat.[3] The major benefit of the gable top carton is the application of graphics and decorations on the packaging which provides a visual impact for the consumer.[3]

Processing & Manufacturing

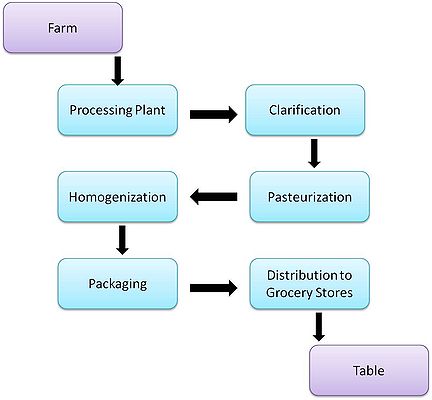

Farm to Table

These five steps are generally universal throughout the world, although the order they are done in may vary such as pasteurization before separation. Canadian processors include a step that adds Vitamin A and D by peristaltic pump to enrich the nutrient content of the milk.[6]

- receiving of raw milk from dairy farmers to the dairy plant[6]

- clarification of raw milk into cream and skim milk[6]

- mixture of cream and skim milk in a specific ratio to produce desired product (skim, 0.5%, 1%, 2%, whole milk)[6]

- pasteurization of milk products to remove unwanted microorganisms[6]

- storage of final products in a controlled environment until distribution to stores.[6]

Centrifuge and Separation (Clarification)

Raw milk is put through series of spinning conical disks at a very high velocity. The fat in milk has a different density than water and therefore the two will separate when centrifuged.

Centrifuge The first several spins will remove debris, bacteria (not all), and sediments from raw milk.[6]

Separation The last several spins will separate raw milk into two layers; milk fat and skim milk.[6] After the milk fat and skim milk are separated, the next step is to mix these two layers in a specific ratio to produce the desired milk product with the correct fat percentage(0.5%, 1%, 2%, 3.25%).[6]

Pasteurization

Pasteurization is the process of heating milk at a certain temperature for a specified amount of time to kill microbes and increase safety for consumers. Below are 3 types of pasteurization: [7]

1. Oldest[7]

- Vat method: milk is held at 60°C for 30 minutes\

2. Most Common[7]

- High Temperature Short Time (HTST): milk is heated to 77°C for 15 seconds. This is currently the most efficient method that allows for retention of milk's sensory properties.

3.Newest (uncommon)[7]

- Ultra High Temperature (UHT): milk is heated to 140°C for less than 8 seconds. This new method is rare as it is still in the development phase as scientists work to perfect it. The major benefit is that it allows for a significantly longer shelf life of milk. The current problem is that the Maillard browning reaction between lactose (sugar) and lysine (an amino acid) causes a change in flavor of the milk that consumers may find undesirable.

Homogenization

Homogenization is the process of breaking fat particles into smaller particles in milk to prevent fat particles from floating to the top; a process known as "creaming". It also helps to evenly distribute fat particles in milk to give a more consistent taste and texture.[8] The hot milk from the pasteurizer is pressurized to 2,500-3,000 psi (17,200-20,700 kPa) by a multiple-cylinder piston pump and is forced through very small passages in an adjustable valve. The shearing effect of being forced through the tiny openings breaks down the fat particles into the proper size.[8] After this process, milk is immediately cooled to 4.4 degrees Celsius to retain it's sensory properties, including taste.[8]

The Raw Milk Debate

Raw milk is unpasteurized milk left in it's natural state[9]. The sale of raw milk is illegal in Canada, but demand from some consumers exists. As pasteurization denatures enzymes, some people believe that raw milk is easier to digest. The counter argument is that these enzymes are not "digestion aiding" to begin with and are ultimately broken down by stomach acid if one was to consume raw milk. As pasteurization is responsible for killing harmful microbes, lack of the pasteurizing process means that raw milk consumers are at risk of ingesting pathogens such as salmonella and listeria. For this reason, the government chose to prohibit the sale of raw milk[9]. There are many people who have a strong opinion about this topic and many lean towards one side of the argument. Others are able to see both sides of the argument, such as Michael Pollan who states, “people should be able to buy raw milk if they want to, but we shouldn’t turn a blind eye to some of the food safety concerns."[10].

What is your opinion on this debate?

Milk as a Starter

Fluid milk is the base of many other foods seen in Canadian's diets. With chemical processes and additional ingredients, milk can be changed from an everyday beverage to a number of different products including specialty cheeses, butter, ice cream, and yoghurt.

Shelf Life

Factors Influencing the Quality and Shelf Life of Milk

Raw Milk Quality

In essence, raw milk is free of microbes when freshly produced by dairy cows.[11] However, pathogens may be introduced through contamination from contact with the external surface of the udder where soil and feces can easily stick to, fecal shedding, and/or an udder infection of the cow. [12]

Although rapid cooling and refrigerated storage reduces the growth rate of mesophilic and thermophilic microbes, it selectively favours the presence of psychrophiles and psychrotrophs, which could be the major cause of milk spoilage.[11] Psychrotrophic microorganisms that are capable of growing in milk at temperatures close to 0 °C are represented by both Gram-negative bacteria (such as Pseudomonas, Achromobacter, Aeromonas, Serratia, Alcaligenes, Chromobacterium, and Flavobacterium spp.) and Gram-positive bacteria (such as Bacillus, Clostridium, Corynebacterium, Streptococcus, Lactobacillus, and Microbacterium spp.).[13] Pseudomonas spp. has been regarded as spoilage bacteria because of its ability to multiply in dairy products kept at low temperature.[11]

Effective pasteurization (i.e., HTST and UHT) kills most microbes but some microbial metabolites are heat resistant and thus remain functional in pasteurized milk to decrease shelf life and sensory quality.[11] Such defects are noticeable if only these heat stable enzymes are abundant in high microbial cell numbers present in raw milk.[11] Strategies such as sanitation and keeping milk at low temperatures are used to reduce microbial load before the pasteurization process.[11] Only pasteurizing milk can guarantee that the milk is safe for consumption, as it will destroy most of the pathogenic bacteria found in milk.

Post-pasteurization Contamination

Post-pasteurization contamination encompasses the recontamination of the product anywhere downstream of the end of the holding tube.[12] It can occur in the regeneration or cooling sections, in storage tanks and in the final packaging of the product, due to poor hygienic practices.[12] Post-pasteurization contamination of milk with psychrotrophic gram-negative bacteria has typically limited shelf life of conventionally pasteurized milk to 14-17 days.[14] Today, improved post-pasteurization milk handling and packaging conditions have eliminated the gram-negative spoilage problem however researchers revealed the presence of a smaller number of heat-resistant psychrotrophic gram-positive bacteria such as Bacillus spp. and microbacter.[14] Elimination of these spoilage organisms is the next hurdle to extending the shelf life of HTST-pasteurized fluid milk.[14]

Storage

Milk requires specific temperature controls to ensure microbial growth is inhibited and quality is maintained. The optimum temperature for prevention of milk spoilage is 4°C or less[15]. In general the lower the storage temperature, the longer the shelf life.[12] Experiments have confirmed that pasteurized milk produced from high quality raw milk could be stored up to 20 days at 8°C, between 30 to 40 days at 4°C, and up to 60 days at 2°C. [12]The Government of Canada recommends milk which is refrigerated and unopened is safe for consumption up until the best before date.[16]

Standards & Regulations

Standards of Identity

Milk has a standard of identity under the Food Regulations of the Food and Drugs Act of Canada[17]. These standards are regulated by the Canadian Food Inspection Agency (CFIA) and ensure that Canadian’s are receiving a consistent product in terms of quality and nutrition.

- Milk or Whole Milk[17].

- The normal lacteal secretion obtained from the mammary gland of the cow (whole milk sold as 3.25% milk fat (MF))

- Contains between 300 and 400 International Units (IU) of vitamin D per reasonable daily intake of milk

- Skim Milk[17].

- No more than 0.3% MF

- Contains between 1200 IU and 2500 IU of vitamin A per reasonable daily intake of milk

- Contains between 300 and 400 International Units IU of vitamin D per reasonable daily intake

- Partly Skimmed Milk or Partially Skimmed Milk[17].

- Derived from milk that has had its fat content reduced by mechanical separation or adjusted by the addition of cream or other milk (results in milk such as 0.5% MF, 1% MF, and 2% MF)

- Contains between 1200 IU and 2500 IU of vitamin A per reasonable daily intake of milk

- Contains between 300 and 400 IU of vitamin D per reasonable daily intake

The reasonable daily intake of milk as noted by the CFIA is 852 mL (approx. 3.5 cups)[18]

Additives & Ingredients

Canadian milk contains no additives, no artificial hormones, and no antibiotics. The only substances allowed to be added to milk as it is defined are fat soluble vitamins A and D. To meet the above standards, it is necessary for vitamin D to be added to all milk and vitamin A to be added to skim and partially skimmed milk[17].

In the case of flavoured milks, such as chocolate, certain ingredients and additives may be needed to suspend the flavor particles throughout the product. Carrageenan is a common suspending agent used in chocolate milk which keeps the cocoa evenly distributed. [19]

Recombinant bovine somatotropin or rBST is a hormone that increases milk production in dairy cows[20]. It is used in the United States, has received media coverage as a controversial topic, and has come to the attention of Canadians. However, it is NOT permitted for use in Canada and any milk purchased in Canada will not contain this hormone[20].

Antibiotics in milk are also strictly prohibited in Canada[21]. If a cow is ill and must receive antibiotics, it is taken off the supply line until it is healthy and can produce milk free of antibiotics and contaminants.

If a farmer is to supply a producer with a load of milk containing artificial hormones or antibiotics, the milk must be discarded[21]. The farmer is responsible for discarding fees as well as a paying a fine for supplying contaminated milk[21]. The large cost to the farmer for producing milk not up to standards is an incentive to produce high quality milk.

To learn more about dairy farmers of Canada and where your milk comes from, visit: http://www.dairyfarmers.ca/

Nutrition

Recommendations

Milk is endorsed by the government as a nutritious product[7]. Milk provides an efficient and convenient way for Canadians to get many nutrients - mainly but not limited to calcium and vitamin D. Fat soluble Vitamins A & D are added to milk. Milk remains one of the best sources for calcium as it has a high content and bioavailability. Some people are under the impression that green veggies and legumes are a great source of calcium. They can be but to put it into perspective, spinach has a calcium bioavailability of 5% where milk is around 25-40%. Broccoli has a high bioavailability of 50% but you'd need to eat 2.5 cups of it to get as much calcium as one cup of milk. [7]

The Food Guide recommends a certain number of servings per day of milk and alternatives: 2-4 servings for children, 3-4 servings for teens, and 2-3 servings for adults [22]. Servings are defined as follows: one Food Guide Serving of milk or of an alternative to milk is [23]:

- 250 mL (1 cup) milk or fortified soy beverage

- 175 g (¾ cup) yogurt

- 50 g (1 ½ oz.) cheese

The Food Guide also makes recommendations to guide consumers in choosing the correct dairy for their lifestyle[24]. Drink skim, 1% or 2% milk each day as opposed to higher fat milks to avoid large intake of saturated fat. Have 500 mL (2 cups) of milk every day to obtain adequate amounts of vitamin D. Drink fortified soy beverages if you do not drink milk and select lower fat milk alternatives[24].

You can explore Canada's Food Guide and see more personalized recommendations here: http://www.hc-sc.gc.ca/fn-an/food-guide-aliment/index-eng.php

Canadian's Consumption

Every year, the Canadian Dairy Information Centre from Agriculture and Agri-Food Canada releases per capita consumption data on various food items according to food availability and disappearance data. New data is released each year and reflects the estimated consumption of the previous year.[25]

According to Canadian Dairy Information centre, consumption of dairy products has been decreased every year since 1994. [26]

The per capita consumption of fluid milk products for 2013 was 77.55 Liters (207 mL, per day).

Of the Total Fluid Milk consumption, 2% milk represents the largest intake: [26]

- 2% Milk = 35.58 L

- 1% Milk = 16.18 L

- Whole (3.25%) milk = 10.22 L

- Skim milk = 7.25 L

- Milk chocolate drink = 5.94 L

- Buttermilk = 0.38 Litres

Dairy Intolerance

Raw milk typically consist of 87.2% water, 3.7% milk fat, 3.5% protein, 4.9% lactose (sugar), and 0.7% minerals. This composition will vary from breed to breed, as well as farm location and cow's diet.[27] The sugar in milk, lactose, is present in large enough amounts to cause gastrointestinal disturbance to consumers who lack the lactase enzyme[28] . This enzyme is responsible for breaking down the disaccharide lactose into it's monomers (components) and allowing for proper digestion. For those with a lactose intolerance, "lactose free" or lactose-reduced milk is available on the market [28] . Lactose free milk has lactase added to it and therefore lactose is present in it's components - glucose and galactose[19]. Glucose and galactose are significantly sweeter carbohydrates and for this reason lactose-free products taste sweeter[19].

Many health related questions pertaining to dairy as well as up to date research can be found at: http://www.dairynutrition.ca/

Conclusion

Video

Our Thoughts

Throughout our group, there were varying opinions on milk. Some of us drink it regularly and consider it a part of our diets, some prefer non-dairy alternatives such as soy milk, and others do not drink it as it was never a part of their diet growing up. Through this research we have all gained extensive knowledge on the various aspects of milk including production, regulations and research on the product itself. We have gained an appreciation for all of these aspects which go into ensuring Canadian milk is a safe, high quality product. Overall, we agree that Canadian milk is a quality product and great choice for those who choose to drink it.

Final Exam Question

Which of the following statements regarding Canadian milk is false?

- A. Canadian milk is fortified with Vitamin D.

- B. Canadian milk is most commonly pasteurized using high temperature short time pasteurization.

- C. The use of plastic bottles in milk packaging involves the use of a tamper-proof cap to seal the product.

- D. Canadian cows are fed hormones to increase their output of milk production.

- E. The most commonly consumed milk variety in Canada is 2 %.

Answer: D is false. Canadian milk is free of additives and artificial hormones. Canadian milk is fortified with Vitamin D to aid in calcium absorption. Skim milk is also fortified with Vitamin A. Canadian milk is most commonly heated at 77°C for 15 seconds to kill microbes. The process is called high temperature short time pasteurization. Plastic bottles are fitted with a tamper-proof lid which will show customers if a bottle of milk has been tampered with. 2 % is the most popular milk variety in Canada with 1 % and whole milk as second and third, respectively.

References

- ↑ 1.0 1.1 1.2 Dairygoodness. (2014). The History of Milk. Retrieved from http://www.dairygoodness.ca/milk/the-history-of-milk

- ↑ 2.0 2.1 Canadian Public Health Leader. (2014). The Story of Milk. Retrieved from http://www.cpha.ca/en/programs/history/achievements/09-shf/milk.aspx

- ↑ 3.00 3.01 3.02 3.03 3.04 3.05 3.06 3.07 3.08 3.09 3.10 3.11 3.12 3.13 3.14 3.15 3.16 3.17 3.18 3.19 3.20 3.21 3.22 3.23 3.24 3.25 3.26 3.27 3.28 3.29 3.30 3.31 3.32 3.33 3.34 3.35 Brody, A.L. (2008). Dairy Processing & Quality Assurance. Oxford, UK: Wiley-Blackwell. 443-464. Doi:10.1002/9780813804033.ch20

- ↑ 4.00 4.01 4.02 4.03 4.04 4.05 4.06 4.07 4.08 4.09 4.10 4.11 Morawicki, R.O. (2012). Handbook of Sustainability for the Food Sciences. Oxford, UK: Wiley-Blackwell. 285-312. Doi. 10.1002/9780470963166.ch12,

- ↑ Keoleian, G.A. Spitzley, D.V. (1999). Guidance for Improving Life-Cycle Design and Management of Milk Packaging. Journal of Industrial Ecology 3(1): 111-126. Doi.10.1162/108819899569322

- ↑ 6.0 6.1 6.2 6.3 6.4 6.5 6.6 6.7 6.8 Hui, Y.H., ed. Encyclopedia of Food Science and Technology. John Wiley and Sons Inc., 2002. pp. 12-43

- ↑ 7.0 7.1 7.2 7.3 7.4 7.5 Skura, B. (2014). B.C.'s Dairy System, Processing and Marketing. Retrieved from LFS 250 online lecture notes, Unit 2 part 3. Cite error: Invalid

<ref>tag; name "B.C.'s Dairy System, Processing and Marketing" defined multiple times with different content - ↑ 8.0 8.1 8.2 Goff, Douglas (2010). "Homogenization of Milk and Milk Products". Dairy Science and Technology. University of Guelph. Retrieved 8 February 2011.

- ↑ 9.0 9.1 BC Dairy Association (2014). "Raw Milk Q & A". Retrieved from http://bcdairy.ca/milk/articles/raw-milk-qa/

- ↑ Real Raw Milk Facts(2014). "What are the real benefits and risks of drinking raw milk?" Retrieved from http://www.realrawmilkfacts.com/

- ↑ 11.0 11.1 11.2 11.3 11.4 11.5 Yeung, M. (2012). ADSA Foundation Scholar Award: Trends in Culture-independent Methods for Assessing Dairy Food Quality and Safety: Emerging Metagenomic Tools. Journal of Dairy Science, 95.12, 6831-6842. doi:10.3168/jds.2012-5677

- ↑ 12.0 12.1 12.2 12.3 12.4 Griffiths, M.W. (2010). Improving the Safety and Quality of Milk, Volume 1 - Milk Production and Processing. Woodhead Publishing. Retrieved from: http://app.knovel.com/hotlink/toc/id:kpISQMVMP3/improving-safety-quality

- ↑ Chavan, R.S., Khedkar, C.D., & Jana, A.H. (2011). UHT Milk Processing and Effect of Plasmin Activity on Shelf Life: A Review. Comprehensive Reviews in Food Science and Food Safety, 10.5, 251-68. doi:10.1111/j.1541-4337.2011.00157.x

- ↑ 14.0 14.1 14.2 Barbano, D.M. (2006). Influence of raw milk quality on fluid shelf life. Journal of Dairy Science, 89, E15-E19. doi:10.3168/jds.S0022-0302(06)72360-8 Cite error: Invalid

<ref>tag; name "barbano" defined multiple times with different content - ↑ CFIA, Government of Canada. (2014, Mar 13). Dairy Establishment Inspection Manual – Chapter 10 Prerequisite. Retrieved from http://www.inspection.gc.ca/food/dairy-products/manuals-inspection-procedures/dairy-establishment-inspection-manual/chapter-10/eng/1371582212731/1371582214294?chap=2

- ↑ Government of Canada. (2014, Mar 20). Safe Food Storage. Retrieved from http://healthycanadians.gc.ca/eating-nutrition/safety-salubrite/storage-entreposage-eng.php

- ↑ 17.0 17.1 17.2 17.3 17.4 Government of Canada. (2014, Jan 29). Food and Drug Regulations - Division 8 Dairy Products. Retrieved from http://laws-lois.justice.gc.ca/eng/regulations/C.R.C.,_c._870/page-87.html#h-74

- ↑ CFIA, Government of Canada. (2014, Mar 11). Reasonable Daily Intake for Various Foods. Retrieved from http://www.inspection.gc.ca/food/labelling/food-labelling-for-industry/nutrition-labelling/information-within-the-nutrition-facts-table/eng/1389198568400/1389198597278?chap=6

- ↑ 19.0 19.1 19.2 Chan, Judy. (2014, Jan 3). Chemical and Physical Properties of Food. Retrieved from https://wiki.ubc.ca/Course:FNH200/Lesson_02

- ↑ 20.0 20.1 University of Guelph. (2014). Safety of Canadian Milk. Retrieved from https://www.uoguelph.ca/foodsafetynetwork/safety-canadian-milk

- ↑ 21.0 21.1 21.2 Dairy Farmers of Canada. (2014). Our Commitment to Food Safety. Retrieved from http://www.dairyfarmers.ca/our-commitments/to-food-safety

- ↑ Health Canada.(2014). How Much Food You Need Every Day. Retrieved from http://www.hc-sc.gc.ca/fn-an/food-guide-aliment/basics-base/quantit-eng.php

- ↑ Health Canada.(2014). What is a Food Guide Serving?. Retrieved from http://www.hc-sc.gc.ca/fn-an/food-guide-aliment/basics-base/serving-portion-eng.php

- ↑ 24.0 24.1 Health Canada.(2014). Tips for Milk and Alternatives. Retrieved from http://www.hc-sc.gc.ca/fn-an/food-guide-aliment/choose-choix/milk-lait/tips-trucs-eng.php

- ↑ Canadian Diary Information Centre. (2013). Sales of Fluid Milk and Cream. Retrieved from http://www.dairyinfo.gc.ca/index_e.php?s1=dff-fcil&s2=proc-trans&s3=mcs-vlc

- ↑ 26.0 26.1 Canadian Dairy Information Centre – Dairy Facts and Figures. (2013). Consumption of Dairy Products (Annual). Retrieved from http://www.dairyinfo.gc.ca/index_e.php?s1=dff fcil&s2=cons&s3=conscdn&s4=consmclc&page=consmclc#mc-lc-can

- ↑ McGee, Harold (2004). "Milk and Dairy Products". On Food and Cooking: The Science and Lore of the Kitchen (2nd ed.). New York: Scribner. pp. 7–67

- ↑ 28.0 28.1 Canadian Digestive Health Foundation.(2014). "Lactose Intolerance". Retrieved from http://www.cdhf.ca/en/disorders/details/id/13

|

|