Life Cycle Analysis of Plastic Grocery Bags

| Global Environmental History | |

|---|---|

| |

| HIST 106 | |

| Section: | 1 |

| Instructor: | Eagle Glassheim |

| Email: | |

| Office: | |

| Office Hours: | |

| Class Schedule: | |

| Classroom: | Online |

| Important Course Pages | |

| Syllabus | |

| Lecture Notes | |

| Assignments | |

| Course Discussion | |

| [[Category:]] | |

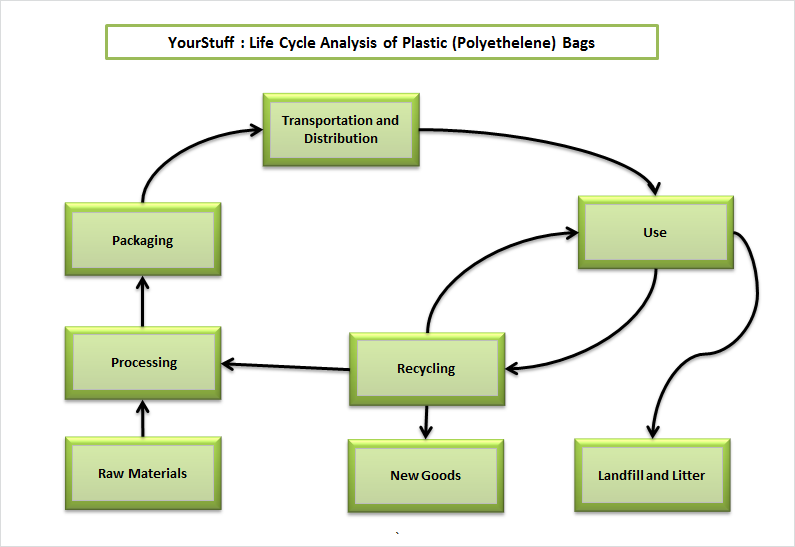

Introduction

Plastic bags have become one of the most ubiqitous consumer items on the planet today. Each day shoppers everywhere use the bags to bring home their groceries and newly purchased items only to discard the bags after one use. Plastic bags litter the sidewalks of our cities and line the banks of rivers and creeks that run through our towns. Not only are the collections of discarded bags unattractive, but they can be deadly as well. Each year millions of marine animals die from ingesting or becoming tangled in plastic bags [1]. Since the plastic is made from petroleum it can be argued that the bags create a comparable level of environmental impacts as harvesting fossil fuels. One study also found that many of the inks used to produce logos on bags contained lead and are not even suitable for carrying food. Today plastic bags have become a widely debated topic in society. Many cities and companies have gone as far as to ban the distribution of the items. Even so, billions of plastic bags find their way to consumers each year. This page will look at the life cycle of the plastic bag and provide an overview of the composition, production and usage as well as outline the energy inputs and outputs during the cycle.

Material Culture/Usage

Plastic bags have become a pervasive icon of convenence and symbolize the emphasis on fast and easy solutions in many societies today. Although the first plastic bag was invented in 1967, it was in the 1970's that retailers began distributing the bags to consumers [2]. Today it is estimated that every minute, humans use about 1 million plastic bags[3]. Although many people today are choosing to bring their own reusable shopping bags, total yearly consumption is still a staggering number estimated in the billions [4].Part of the issue is not that plastic is necessarily preferred over other materials; it’s that many societies place a value on the most accessible and fastest option. Since it is easier to use plastic bags from the store, instead of making it a habit to bring reusable cloth bags, the plastic bag is prevailing despite the debates. However as the accessibility of studies and information on environmental impacts are becoming more readily available, more people each day are realizing the impacts of their choices. Some consumers have begun to eliminate plastic bags from their shopping routines or have found ways to slightly extend the life of their bags by reusing them. Although it is a good start to the solution, even with reuse the bags are generally used only one more time as a garbage can liner or to pick up after a pet. So although many consumers are choosing to reuse their bag in some way, the detrimental effect of a plastic bag's entire life cycle greatly outweighs the generally short lived purpose it serves. The issue at hand is not just how to reduce the use of plastic bags, but how to actualize the change in a society dependent on their culture of convenience.

Energy Usage

Energy is the driving force behind every stage in the life cycle of plastic bags. This energy is usually produced from non-renewable resources, such as fossil fuels. Even the building blocks of a polyethylene bag are made from these non-renewable resources.

Feedstock energy is the energy embodied within a physical material. In the case of plastic bags, the feedstock energy is the energy that was consumed in order to produce the High Density Polyethylene (HDPE).It is usually a combination of the energy required to extract, process, and transport the raw materials.

Process energy is the energy used in production of a physical material. For plastic bags, this may include the polymerization and extrusion processes.

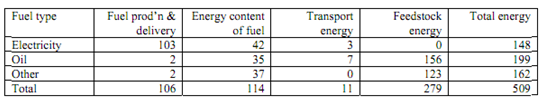

In one estimate, a single plastic bag uses 495kJ of natural gas, 120 kJ of petroleum, and 80 kJ of coal[5]. Another found that 1500 plastic bags use 159 MJ in fuel production, 171 MJ in fuel use, 16 MJ in transportation, and 418 MJ in feedstock, for a total of 763 MJ. Per bag, this equates to 508 kJ in total energy use [6].

It should be noted that estimates are vulnerable to variability, due to the numerous assumptions that must be made to come up with these values. These estimations include assumptions such as:

- Sources of oil, gas, and electricity

- Location of manufacturing and processing

- Efficiency of manufacturing and processing

- Location of usage

- End use of product (how many times it is reused, etc)

- Disposal method (landfill, incineration, etc)

The following table is the amount of energy in mega joules (MJ) which goes into 1000 polyethylene bags.

Transportation

A major contributor to the environmental impact of the plastic bag is the transportation that it takes to get the bag to its final consumer. The production of the bags require the raw materials to first be transported to the different levels of manufacturers and once created, are transported out to retailers everywhere. The carbon emissions expelled by the transportation during the life cycle of the plastic bag have a harmful effect on the environment. Since retailers cannot store all the bags that they will require throughout the year, they receive shipments often. This means that the carbon footprint created by the transporting of bags is an ongoing process, with more bags being create and shipped each day. The cost of the transportation and bags, estimated at $4 billion dollars annually to American retailers alone, is then passed on to consumers in the form of higher product prices [8]. Since the bags are generally a one-time use item, they are then transported to the landfills. In effect, each time a new plastic bag is used and discarded, the entire production cycle has to begin again and the raw materials are once again transported to first stage of the manufacturing process. The frequency of carbon emissions during the different transportation stages, illustrates one of the many harming effects that plastic bags have on the environment.

Raw Materials

The main components of polyethylene are natural gas and petroleum. Extraction of both products is energy intensive. This is increasingly true as tapped wells become less productive, and supplementary methods are required to continue extraction (ex 'fracking' or hydraulic fracturing). After extraction, the raw materials must be refined, adding to the energy consumed. Extracted natural gas is often referred to as 'sour,' a term used for gas containing large amounts of sulphuric acid. Before it can be efficiently used, the gas must be turned 'sweet' by removing the sulphuric acid. These processes add to the embodied energy of the raw materials of plastic bags, before production has even begun.

Production

Once transported to a processing facility, the raw materials are treated to create monomers (mers), like ethylene and propylene. These mers are the basis of many plastics like polypropylene -or in the case of plastic bags- polyethylene. They can be further processed to create the various other types of plastic monomers. Mers undergo further manipulation, called polymerization, to form long chains, which are essentially the backbone of the plastic polymer. For the production of plastic bags, the raw polyethylene is shipped in granule form. At the production facility, the granules are loaded into a hopper, along with recycled polyethylene chips, if available. They are then carried to a heated chamber, called an extruder. The granules are mixed and worked, and then thinned into a film through a tool called a die. At the output of the extruder, the polyethylene is thin enough to form into plastic bags.

In the United States, polyethylene is the most consumed polymer, nearly doubling the nearest contender, polystyrene. Consumption of Polyethylene is estimated at 9 million tonnes per year[9]. A large portion of polyethylene is turned into consumer products and packaging, such as bottles, plastic film, and shopping bags. Many of the objects created out of polyethylene are designated as non-durables: their useful life is designed to be less than three years. Furthermore, most of these polyethylene objects will skip the recycling stage and go straight to disposal.

Recycling

It is estimated that only one percent of plastic bags are recycled worldwide[10]After primary use however, polyethylene bags can be recycled in numerous ways. Even without reprocessing, plastic grocery bags can be re-used as garbage bags or shopping bags. Otherwise, the polyethylene can be reprocessed and create new plastic bags, or other goods such as clothing and containers.

By some estimates, 60 percent of the United States population have access to recycling programs. These are often in the form of curbside collection and drop-off centers. But Americans only recycle 0.6 percent of the 100 billion plastic bags taken home. The remainder usually ends up as litter or at a landfill [11]. The recycling rate of plastic bags has influence on the embodied energy within them. Through recycling, feedstock energy can be reduced. Additionally, the amount of petroleum and natural gas required for raw materials can be cut by up to 25% and 50%, respectively[12]

Each type of plastic requires a different processing technique. As such, when sent to recycling facilities, they are sorted by polymer type. Plastic bags are sorted into a HDPE collection, where they are compressed and baled. Then they are shipped to a reclaimer. Here, the bags and other assorted HDPE are cut into small flakes, washed, and sold to container or bag manufacturers[13]. When making bags out of recycled material, the strength and appearance significantly deteriorate[14]. Also, due to the possibility of contamination, the recycled polyethylene may be unhygienic. Therefore, many “recycled” plastic bags are not made out of 100% recyclable materials. In some cases, the energy and costs of recycling plastic bags exceeds the energy usage and cost of creating new ones[15].

Litter and Landfills

Despite increased efforts to reduce plastic bag usage and increase recycling rates, the vast majority of plastic bags still end up in the landfill or as litter. On average, a plastic bag is used for a mere twelve minutes[16], while they can take more than 25 years to break down. This means that they spend about 45360 times longer in a landfill then they spend being used. The bags which end up at the landfill may not end up staying there. Forty-seven percent of litter leaving the landfill by wind is plastic, most of which are plastic bags. This litter may end up in the forests, rivers, and ocean. There are approximately 46,000 pieces of plastic floating in each square mile of the world’s oceans. And plastic bags are in the top 12 items of debris found in marine clean ups[17].

According to some researchers, polyethylene cannot actually bio-degrade. It can break down into synthetic granules if exposed to the ultraviolet radiation from the sun. However, it is not proven that these granules completely break down. Therefore, they may cause harm to wildlife and marine environments. Plastic bag litter has had a major effect on marine ecosystems. Animals such as turtles, seals, birds, and whales have been found to suffocate, become entangled, and starve due to blockages in their digestive systems[18]. In one situation, in 2002, a minke whale that was beached in Normandy was found to have 800g of plastic in its stomach[19].

The Ban of Plastic Bags

Due to the environmental concerns of the consumption of plastic bags, many municipalities, states, and countries have been fighting to tax or ban them. Plastic bag taxes in Italy and Belgium have been implemented. Other countries such as Spain, Norway, and Germany make their grocery shoppers pay for their plastic bags[20]. In 2002, Bangladesh banned plastic bags after the blocking of drains contributed to flooding in 1988 and 1998[21]. In two locations in Texas, Whole Foods Market[22] has stopped offering plastic bags, and instead are using 100% recycled paper bags[23]. Ireland has reduced consumption by implementing a tax on the bags. The levy has cut plastic bag usage by over 90%[24]. However, plastic garbage bags increased in sales by about 300-400%[25].

Paper or Plastic?

Despite popular belief, paper bags are not a sustainable alternative to plastic. Polyethylene bags consume about 40% less energy than paper[26]. They also produce 80% less solid waste and 70% fewer emissions. Plastic bags typically have less mass than paper ones, produce less solid wastes, and take up less space in landfills. Even if both bags are recycled at the same rate, paper bags produce 35% more atmospheric waste. At the current recycling practices, polyethylene bags use less energy, and waste[27]. There are many misinformed people who believe that they are being more sustainable by choosing paper. A better solution is to use cloth bags or totes that can be reused indefinitely.