Documentation:Gas Vial Evacuation

Appearance

Setup and System Maintenance

- Remove red protector from the oil exhaust port on the vacuum pump and unscrew the mesh cap (Figure 1).

- Ensure the oil drainage plug is screwed in tightly, pour vacuum oil into oil exhaust port until the oil level reaches the fill line on the sight glass.

- Replace the mesh cap on the oil exhaust port.

- Remove the black cap from the secondary inlet and ensure the valve is in the open position.

- Screw all 4 disposable needles onto the manifold firmly, and remove their protective caps (Figure 2).

- Plug in and turn on the vacuum pump with the rear power switch.

Evacuation

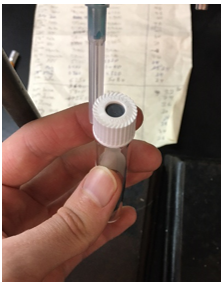

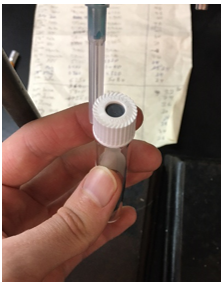

- Gently insert needle tips through the center of the septa on the vials one by one (Figure 3).

- Replace the black cap onto the secondary inlet, screwing tightly to pressurize system. Start recording the evacuation time from this point.

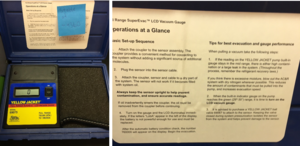

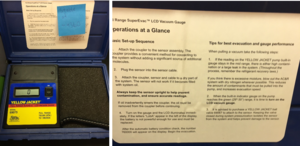

- Once the analog pressure reading on the vacuum pump reaches the green area on the gauge, turn on the digital pressure gauge (Figure 4).

- Evacuate vials for at least 1 minute or until pressure reading stabilizes on the digital pressure gauge (approx. 5,000).

- Turn off the digital pressure gauge.

Figure 3. Gas vial with septum used for gas sampling. - Remove all 4 vials from the needles together in one swift motion – any not removed at the same time may be compromised.

- Remove black cap from the from secondary inlet, allowing system to de-pressurize entirely.

- Repeat evacuation steps 1-7 until all vials are successfully evacuated.

Cleanup

- Turn off the vacuum pump with the rear power switch.

- Replace caps onto needles and use the caps to unscrew the needles (use pliers if needed) dispose of bent needles in sharps container.

- Replace black cap onto the secondary inlet.

- Change pump oil when it is maple in colour. Drain oil while it is still hot by carefully unscrewing plug from the oil drainage pot on the front of the vacuum. Use a funnel to help direct the oil back into the bottle.

- Replace drainage plug tightly.

- Replace red protector to exhaust port on top of vacuum pump.

- Unplug vacuum pump.

Figure 4. Yellow Jacket vacuum pressure gauge.

Additional Information

- To read the manual for the vacuum pump: https://muquip.triumf.ca/sites/default/files//instruction_manuals/Yellow-Jacket-SuperEvac-Vacuum-Gauge-93580-Manual.pdf

- To read the manual for the Gauge Monitor: https://yellowjacket.com/wp-content/uploads/2015/01/180355_Rev.D.pdf