Course:FNH200/2013w Team11 ProteinPowder

Whey Protein Powder

Introduction

What is Whey Protein Powder?

Whey Protein Powders are Natural Health Products used for muscle repair and growth [1]. They are popular among athletes, body-builders, and physically active individuals.

Whey protein powders are highly effective due to high levels of easily digestible essential amino acids and branched chain amino acids, which facilitate muscle gain [2]. Gold Standard Whey contains hydrolyzed whey, which means the whey is partially broken down prior to consumption. These branch chain amino acids are quickly broken down in the gastrointestinal tract, and rapidly absorbed from the small intestine into the bloodstream.

The History of Whey Protein

It is estimated that whey was discovered 3000 years ago, completely by accident [3]. Calves' stomachs, which naturally contain the coagulating enzyme chymosin (rennet), were commonly used to store milk. The enzymatic action of chymosin would produce curds and whey from the milk. Most people are familiar with the role of curds in cheesemaking, but may not be as well acquainted with whey.

Whey is an acidic, thin liquid obtained from coagulating and pressing curds during cheesemaking [4]. Whey derived from cheesemaking is typically yellow-green in colour and has a pH of 5.9 - 6.6 [5]. As such, whey is considered a low-acid food.

Though the cheese-producing curd was quickly deemed valuable for its nutritive value and delicious taste, the benefits of whey were not immediately recognized [6]. Whey was largely considered a waste product by cheese-makers, who sought to dispose of it in the most economical way possible. Many of these disposal methods were ecologically harmful, such as discharging whey into nearby lakes, rivers, and municipal sewage systems. The environmental impact of these practices spurred legislation regarding whey disposal, which ultimately increased the overall cost of dealing with this by-product [7].

As the costs of disposing of whey increased, cheese manufacturers sought new ways to utilize whey. Advances in processing technology, such as ultrafiltration, microfiltration, and reverse osmosis, transformed whey from an unwanted by-product to a high-value commodity [8] [9].

Whey Today

Whey protein powders are the result of isolating, concentrating, and dehydrating liquid whey [10]. Manufacturers such as Optimum Nutrition have increased the palatability of dehydrated whey by adding sugars and flavourings. There are many different flavours of Gold Standard Whey Protein, including vanilla ice cream, chocolate mint, and tropical punch.

Dehydrated whey protein powders reconstitute quickly when added to liquid, which makes them a quick and convenient supplement. Optimum Nutrition recommends using 30g of Gold Standard Whey Protein for every 250mL of liquid (i.e. water, milk). Protein powder can also by easily incorporated into fruit and vegetable smoothies. Many recipes incorporate protein powder to increase overall nutrition and satiety. However, long exposure to very high temperatures can denature proteins [11]; as such, when cooking with protein powders it is recommended to use lower temperatures.

Preservation and Processing

Preservation

It is preferable to process whey immediately, since its nutrient content is conducive for the growth of microbes. If immediate processing is not possible, whey is kept at 5⁰C to inhibit the growth of bacteria. The first step of whey processing is the separation of the fat and casein fines. Casein is the major protein found in milk. Casein and fat are separated by the use of cyclones, centrifugal separators, and rotating filters[12].

After fat and casein separation, whey undergoes dehydration processes to reduce the overall water content. This typically takes place under vacuum in a falling film evaporator; other methods, such as reverse osmosis, may also be used. After evaporation to a content of 40-65% remaining solids, the whey concentrate is cooled rapidly to 30⁰C in a plate heat exchanger. The whey is then further cooled to 15-20⁰C in a secondary triple jacketed tank. This process continues for 6-8 hours, to ensure that small water-excluding particles will form when the product is spray dried[13].

Ultrafiltration is used to further concentrate dehydrated whey in order to produce Whey Protein Concentrate. There are three main protein compositions: 35% WPC, 60% WPC and 80% WPC. Ultrafiltration selectively strains the desired compounds through a porous membrane with a specific pore size. Whey is pressurized and forced through the membrane, separating individual whey particles according to size. Below is a list of components that are usually found in whey and dairy products, along with their respective sizes[14]..

| Particles | Diameter |

|---|---|

| Fat Globules (and Bacteria) | 500-10,000 nm |

| Casein Particles | 10-300 nm |

| Whey Protein | 3-6 nm |

| Lactose | ~1 nm |

| Salts | 0.4-1.0 nm |

| Water | ~0.3 nm |

Drying

The processed whey mix is then dried using a spray or drum dryer. Drum drying is not the most popular option since the layer of dried whey can stick to the surface of the drum. Other adverse effects from using drum dryers include irreversible changes to lactose, caramelization, maillard reaction and protein denaturation. All of these adverse reactions are due to the excessively hot surfaces used in the rolling drum dryers, and can lead to a scorched product. This issue is usually addressed by adding wheat products to the whey mix. This makes the dried layer easier to remove[15].

Spray drying is commonly used in industrial process for particle formation from liquid feedstocks and drying. The process of spray drying works through immense heat and mass transfer in a fraction of time. This begins with the atomization of the liquid into tiny droplets with a diameter close to 50 microns. The droplets are then sprayed into a hot airstream for evaporation. The finished product is a powder composed of small particles which pack well together. The finished whey protein powder exhibits appropriate residual moisture content, bulk density and particle morphology for production and storage standards[16].

Packaging and Storage

Packaging is very important in making sure that the protein powder is usable for the longest possible time without degrading. Whey protein powder has a shelf life of 12 months when stored properly. Whey protein powder is packaged in two ways. The first is to package it in a bag made up of two main components: an outer 3-4 ply multi-wall Kraft paper bag and an inner 3-4 mil thickness low density polyethylene (LDPE) bag liner. Both components seal through the application of heat. The LDPE bag liner has vents that will release the oxygen from the package but will not allow oxygen back into the package. This combination protects the product through storage and handling [17].

The second method of packaging is modified atmosphere packaging (MAP). Oxygen in the headspace is replaced with a gas such as nitrogen, or a mixture of gases. Modified atmosphere packaging allows manufacturers to discourage the microbial growth without compromising the quality of the protein powder. This packaging process helps extend the shelf life of the protein powder [18].

When packaging powder, it is important to store it in a package that will be resistant of moisture absorption. This is to keep the water activity (Aw) low and at a necessary levels. The suggested Aw for protein powder storage is <0.24, to minimize the product changes through storage [19]. The more robust the packaging, the longer the shelf life of the product. This is why protein powder tends to be stored in thick plastic jars. This is because those jars are very resistant to moisture uptake [20].

Temperature and humidity of storage conditions are very important in making sure the product lasts as long as possible. To achieve optimal shelf life, whey protein powder should be stored at 25°C with an approximate humidity below 65%. These conditions are optimal as they are likely to keep Awat less than 0.24. The greatest loss of product quality during storage is due to moisture uptake. The moisture uptake that occurs during mal storage will cause chemical, physical and bacteriological changes to the powder [21]. There are many consequences related to the improper storage of whey protein powder. These include browning/colour changes, clumping, flavour, functionality, and hardening [22].

Browning/colour changes occur due to storage at a temperature higher than 35°C. Storage at this temperature will cause the Maillard Browning Reaction to occur during storage, resulting in the creation of brown pigments. The browning of the powder also changes the functionality of the powder; specifically, the solubility of the whey powder is altered due to the Maillard browning reaction [23].

Clumping can occur in protein powder due to the moisture uptake of the lactose component in the powder. Clumping occurs more frequently in whey powders that contain more lactose [24].

Flavour may be changed due to storage at high temperatures and relatively high humidity. The aromatic constituents responsible for flavour and aroma may be altered in these conditions. This will cause the product to taste different from its usual mild, neutral dairy flavour. The powder may also smell “off” to the consumer [25].

Hardening of whey protein powder occurs when it is exposed to high temperatures and high humidity (>85%) conditions for relatively long period of times. They time needed for hardening to occur varies from product to product [26].

Digestive Issues and Allergies

Whey protein is a common protein found in dairy products. Many people believe that they are lactose intolerant, but their true issue may be that they are unable to digest whey protein [27]. People with whey allergies can experience milk-allergy symptoms when consuming whey protein powder.

Whey protein powder can illicit many different reactions in individuals. Digestive, respiratory, and skin reactions can occur due to the consumption of whey powder. Signs and symptoms of whey allergies are:

- Digestive; stomach cramps, diarrhea and vomiting

- Respiratory; a runny nose, sneezing, and itchy eyes

- Skin; eczema, hives and rashes.

An asthma attack can occur if the consumption of whey is high enough to cause a more severe reaction. If skin reactions occur due to consumption, they are likely to have swelling around the mouth accompanied by redness or a tingly feeling. Symptoms of an allergric reaction can appear minutes to hours after whey consumption [28].

Sensory Properties of Whey

The use of whey proteins is steadily increasing due to consumer demand for the product. Uses of this product include many food products, most notably being bars and beverages [29]. Since the usage of whey proteins is so widespread, sensory perceptions of whey protein in food must be taken into account when using a particular type of whey. For example, whey protein concentrate and whey protein isolate offer two different sensory experiences. The sensory properties of whey can be altered by using a different initial source (i.e. various cheeses) as well as different processing methods [30]. There are other factors that change the colour, flavor, texture and overall acceptance of whey proteins.

The initial liquid whey used in whey protein powder manufacturing is frequently sourced from various types of cheeses. The colouring of whey protein can be due in part to the colour of the cheese from which it was derived. In addition, whey protein concentrates of different protein levels often differ in colour [31]. The natural colour of whey protein (a yellowish colour) is often undesirable to consumers, so whey powder is usually treated with various bleaching agents, such as benzoyl peroxide and hydrogen peroxide. The use of hydrogen peroxide for bleaching leads to lipid oxidation and “off” flavors in whey [32]. In this way, manipulating the colour of whey to appeal to consumers may inadvertently decrease its palatability.

Unpleasant flavours in whey protein are often enhanced with long storage time or deviating temperatures [33]. Naturally unpleasant flavours in whey are the result of many factors, most of which have to do with the composition of the starting material . These factors include: bacterial starter culture concentration; lipid removal from whey; source of milk; variety of cheese used; cheese curd processing before drainage of whey; and storage time [34]. It is important for manufacturers to note the different flavours contributed by either whey protein concentrate or whey protein isolate. Whey protein concentrate contains more carbohydrates and lipids and have a more intense flavour than whey protein isolate [35]. Whey protein concentrates are often also associated with a sweeter taste, due to a higher lipid content.

Many manufacturers add flavorings to their whey protein powders. Gold Standard Whey is no exception to this; this product comes in vast amounts of flavors as previously shown. The intention of the whey protein is to be dissolved in a liquid, usually water, milk or in a smoothie, and then consumed. These added flavors attempt to make the product taste better so that it is better liked by consumers and is purchased more readily.

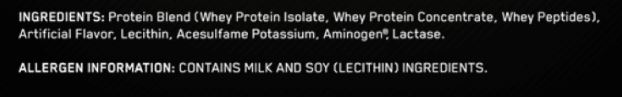

Ingredients and Additives in Gold Standard Whey Protein Powder

Whey protein isolate: whey protein isolate is produced by a combination of microfiltration and ion exchange

- product is over 90% protein

- contains less than 0.5% lactose and milk fat

Whey protein concentrate: ultrafiltration is used to remove lactose, fat, and ash

- in Gold Standard Whey, concentrate contains 80-85% protein

Whey peptides: the casein-derived whey from cheese making is defatted, pasteurized, and dried

Artificial flavour: variable depending on the variety of protein powder

Lecithin: emulsifying agent; prevents solid whey particles from separating when mixed with liquid

Acesulfame-potassium: non-nutritive (calorie-free) sweetener

Aminogen: synthetically-derived enzyme developed by Triarco industries; designed to increase amino acid uptake (Triarco Industries, 2013)

Lactase: enzyme for the breakdown of lactose into glucose and galactose; included in Gold Standard Whey to ensure suitability for lactose-intolerant consumers

Health Risks

There are many health risks associated with the over consumption of proteins. The main risks include an increased risk of osteoporosis, dehydration, and displacement of nutrients.

Consumption of high levels of animal-based proteins are known to increase calcium losses in urine, due to its consumption in the breakdown processing of proteins. Prolonged calcium losses can eventually lead to osteoporosis, especially in women. Overconsumption of protein can also lead to dehydration because protein metabolism requires a substantial amount of water. Excessive protein consumption can also displace other nutrient dense foods. If one is consuming a large amount of protein, dietary intake of fruit, vegetables, legumes and grains may decrease. This decreases overall micronutrient and fibre intakes [36].

Exam Review Question

Based on the material presented above: Why is spray drying used as the preferred drying method compared to drum drying?

- a) Drum Dryers are noisier, and scare animals that live close to food processing plants

- b) Drum Dryers ruin the quality of the product

- c) Drum Dryers consume more energy

- d) Drum Dryers are more likely to break down and have higher maintenance costs

- e) Drum Dryers have a higher cost of per unit, increasing startup costs

Answer: (b)

Drum dryers use temperatures too extreme for the treatment of protein products, leading them to usually get scorched and damaged in drum dryers. Spray dryers allow for particle drying to take place due the ability of smaller droplets to be created, allowing for a higher Surface Area to Volume ratio, allowing evaporation of water to occur at a greater rate at a lower temperature.

Project Video Link

https://www.youtube.com/watch?v=2PXAry_MjZM&feature=youtu.be

References

- ↑ EatRightOntario. (2014). Sports Nutrition: Facts on sports supplements. Retrieved March 25, 2014 from: http://www.eatrightontario.ca/en/Articles/Physical-Activity/Sports-nutrition---Facts-on-sports-supplements.aspx#pro

- ↑ Bylund, Gosta. "Whey Processing." Dairy Processing Handbook. 2003. Reprint. AB, Canada: Tetra Pak Processing Systems, 2009. 331-352. Retrived from http://www.ales2.ualberta.ca/afns/courses/nufs403/PDFs/chapter15.pdf.

- ↑ Smithers, G.W. (2008). Whey and whey proteins - From 'gutter-to-gold'. International Dairy Journal 18(7), 695-704.

- ↑ Bylund, Gosta. "Whey Processing." Dairy Processing Handbook. 2003. Reprint. AB, Canada: Tetra Pak Processing Systems, 2009. 331-352. Retrived from http://www.ales2.ualberta.ca/afns/courses/nufs403/PDFs/chapter15.pdf.

- ↑ Smithers, G.W. (2008). Whey and whey proteins - From 'gutter-to-gold'. International Dairy Journal 18(7), 695-704.

- ↑ Smithers, G.W. (2008). Whey and whey proteins - From 'gutter-to-gold'. International Dairy Journal 18(7), 695-704.

- ↑ Affertsholt, T., & Nielson, W. (2003). Walk this whey. Dairy Industries International. 68(12). 31-32

- ↑ Affertsholt, T., & Nielson, W. (2003). Walk this whey. Dairy Industries International. 68(12). 31-32

- ↑ Marshall, K. (2004). Therapeutic Applications of Whey Protein. Alternative Medicine Review, 9(2), 136-156

- ↑ Bylund, Gosta. "Whey Processing." Dairy Processing Handbook. 2003. Reprint. AB, Canada: Tetra Pak Processing Systems, 2009. 331-352. Retrived from http://www.ales2.ualberta.ca/afns/courses/nufs403/PDFs/chapter15.pdf.

- ↑ Marshall, K. (2004). Therapeutic Applications of Whey Protein. Alternative Medicine Review, 9(2), 136-156

- ↑ Bylund, Gosta. "Whey Processing." Dairy Processing Handbook. 2003. Reprint. AB, Canada: Tetra Pak Processing Systems, 2009. 331-352. Retrived from http://www.ales2.ualberta.ca/afns/courses/nufs403/PDFs/chapter15.pdf.

- ↑ Bylund, Gosta. "Whey Processing." Dairy Processing Handbook. 2003. Reprint. AB, Canada: Tetra Pak Processing Systems, 2009. 331-352. Retrived from http://www.ales2.ualberta.ca/afns/courses/nufs403/PDFs/chapter15.pdf.

- ↑ "Membrane Filtration." from GEA Niro. N.p., n.d. Web. 2 Apr. 2014. <http://www.niro.com/NIRO/cmsdoc.nsf/webdoc/webb7gndlj>

- ↑ "Spray Drying." Technology and Spray Dryer Information from GEA Niro. N.p., n.d. Web. 2 Apr. 2014. <http://www.niro.com/niro/cmsdoc.nsf/WebDoc/ndkk5hmc6zSprayDryersSprayDryers>

- ↑ "Spray Drying." Technology and Spray Dryer Information from GEA Niro. N.p., n.d. Web. 2 Apr. 2014. <http://www.niro.com/niro/cmsdoc.nsf/WebDoc/ndkk5hmc6zSprayDryersSprayDryers>

- ↑ "Optimizing the Quality and Shelf Life of Dairy Ingredients." - Safety and Quality. U.S. Dairy Export Council, n.d. Web. 27 Mar. 2014. <http://www.dairyforglobalnutrition.org/SafeQuality/content.cfm?ItemNumber=88701&navItemNumber=88582>

- ↑ "Optimizing the Quality and Shelf Life of Dairy Ingredients." - Safety and Quality. U.S. Dairy Export Council, n.d. Web. 27 Mar. 2014. <http://www.dairyforglobalnutrition.org/SafeQuality/content.cfm?ItemNumber=88701&navItemNumber=88582>

- ↑ "Optimizing the Quality and Shelf Life of Dairy Ingredients." - Safety and Quality. U.S. Dairy Export Council, n.d. Web. 27 Mar. 2014. <http://www.dairyforglobalnutrition.org/SafeQuality/content.cfm?ItemNumber=88701&navItemNumber=88582>

- ↑ "Optimizing the Quality and Shelf Life of Dairy Ingredients." - Safety and Quality. U.S. Dairy Export Council, n.d. Web. 27 Mar. 2014. <http://www.dairyforglobalnutrition.org/SafeQuality/content.cfm?ItemNumber=88701&navItemNumber=88582>

- ↑ "Optimizing the Quality and Shelf Life of Dairy Ingredients." - Safety and Quality. U.S. Dairy Export Council, n.d. Web. 27 Mar. 2014. <http://www.dairyforglobalnutrition.org/SafeQuality/content.cfm?ItemNumber=88701&navItemNumber=88582>

- ↑ "Optimizing the Quality and Shelf Life of Dairy Ingredients." - Safety and Quality. U.S. Dairy Export Council, n.d. Web. 27 Mar. 2014. <http://www.dairyforglobalnutrition.org/SafeQuality/content.cfm?ItemNumber=88701&navItemNumber=88582>

- ↑ "Optimizing the Quality and Shelf Life of Dairy Ingredients." - Safety and Quality. U.S. Dairy Export Council, n.d. Web. 27 Mar. 2014. <http://www.dairyforglobalnutrition.org/SafeQuality/content.cfm?ItemNumber=88701&navItemNumber=88582>

- ↑ "Optimizing the Quality and Shelf Life of Dairy Ingredients." - Safety and Quality. U.S. Dairy Export Council, n.d. Web. 27 Mar. 2014. <http://www.dairyforglobalnutrition.org/SafeQuality/content.cfm?ItemNumber=88701&navItemNumber=88582>

- ↑ "Optimizing the Quality and Shelf Life of Dairy Ingredients." - Safety and Quality. U.S. Dairy Export Council, n.d. Web. 27 Mar. 2014. <http://www.dairyforglobalnutrition.org/SafeQuality/content.cfm?ItemNumber=88701&navItemNumber=88582>

- ↑ "Optimizing the Quality and Shelf Life of Dairy Ingredients." - Safety and Quality. U.S. Dairy Export Council, n.d. Web. 27 Mar. 2014. <http://www.dairyforglobalnutrition.org/SafeQuality/content.cfm?ItemNumber=88701&navItemNumber=88582>

- ↑ Baker, Coleman. "Allergy Relief Expert." Whey Allergy and everything else you want to know about allergies.. N.p., 2 June 2009. Web. 27 Mar. 2014. <http://www.allergyreliefexpert.com/whey-allergy/>

- ↑ Baker, Coleman. "Allergy Relief Expert." Whey Allergy and everything else you want to know about allergies.. N.p., 2 June 2009. Web. 27 Mar. 2014. <http://www.allergyreliefexpert.com/whey-allergy/>

- ↑ Russell, T.A., Drake, M.A., Gerard, P.D. Sensory Properties of Whey and Soy Proteins. Journal of Food Science. 71(6). 447-455

- ↑ Mortenson, M.A., Vickers, Z.M., Reinecciou, G.A. Flavor of whey protein concentrates and isolates. International Dairy Journal. 18(6). 649-657

- ↑ Lammert, A., Olabi, A., Kalache, L., Brooks, K., Tong, P. Characterisation of the sensory properties of whey protein concentrates. International Journal of Diary Technology. 67(1). 135-141

- ↑ Jervis, S., Campbell, R., Wojciechowski, K.L., Foegeding, E.A., Drake, M.A., Barbano, D.M. Effect of bleaching whey on sensory and functional properties of 80% whey protein concentrate. Journal of Dairy Science. 95(6). 2848-2862

- ↑ Lammert, A., Olabi, A., Kalache, L., Brooks, K., Tong, P. Characterisation of the sensory properties of whey protein concentrates. International Journal of Diary Technology. 67(1). 135-141

- ↑ Lammert, A., Olabi, A., Kalache, L., Brooks, K., Tong, P. Characterisation of the sensory properties of whey protein concentrates. International Journal of Diary Technology. 67(1). 135-141

- ↑ Russell, T.A., Drake, M.A., Gerard, P.D. Sensory Properties of Whey and Soy Proteins. Journal of Food Science. 71(6). 447-455

- ↑ Hammond, G. 2014. UBC FNH 250 Class Notes: Proteins