Course:FNH200/2013w Team10 ImitationCrab

Introduction

Overview

Have you ever wondered what ingredients go into the ketchup you eat with your burgers and fries? Have you ever questioned the steps in production to make the smooth, red sauce we all love?

This project aims to define ketchup and discover the processes of ketchup production, preservation, packing and regulation.

Some questions you may have about ketchup are: What country did ketchup originate in? How are the tomatoes used for ketchup chosen? How is ketchup processed, packaged, and preserved? What are the current regulations for ketchup?

After reading this page, you should be able to find the answers to the questions listed above.

Ketchup, also known as catsup, is a smooth, sweet, and tangy red sauce made from tomatoes (How Products Are Made, 2014). Ketchup has a variety of spices added to it and is often used to augment flavour. It is a condiment that is widely used due to its various culinary uses. This seasoned tomato sauce is most commonly used on French fries, hamburgers, hot dogs, and sandwiches. It is also used as an ingredient for other sauces and can be incorporated in recipes as a seasoning for meat, beans, stews and meatloaf (How Products Are Made, 2014).

History/Background

Contrary to popular belief, ketchup originated from Asia, even though tomatoes are native to America (Gandhi, 2013). Ketchup was first found in Fujian, a province in China. Before it was called ketchup, its name was ke-tsiap in Hokkien Chinese. Instead of tomato, the main ingredient was actually fish; the original name, ke-tsiap, means pickled fish sauce. Unlike the modern tangy tomato ketchup, it had a savory taste. Chinese traders then brought this pickle fish sauce to other parts of Asia, such as Malaysia and Indonesia. Before it was brought to other parts of the world, it was mainly homemade.

In the 1600s, the Dutch and English sailors encountered this pickled fish sauce and brought it back to Europe. This is when the name was changed to “ketchup”. The reason why ketchup was so popular was that it could be kept for several months without spoiling(good preservation). In the early 1700s, ketchup became widespread in Europe. A variety of spices became available to make tasty ketchup, such as pepper, cinnamon, and mustard seed. In the early 1800s, a variety of ketchup was introduced by the English. There were walnut, lemon, oyster, mushroom, anchovy ketchup, etc (Gandhi, 2013).

During the colonial period, the ketchup was brought to the United States by the British. Since tomato is native to the United States, the tomato ketchup was invented here (Gandhi, 2013). The first recipe of tomato ketchup was written and published by a scientist and horticulturalist, James Mease, from Philadelphia in 1812. Thereafter , varieties of tomato recipes were invented. Ketchup became popular and widely available in the US in the 1870s. In the 1890s, it was awarded as “the king of all sauces”, and declared as the American national condiment that could be found on “every table” (Gandhi, 2013). In 1882, the Heinz Company started packing the ketchup in easy-to-use plastic bottles (Gandhi, 2013).

Regulation

Please go to http://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=155.194

Production

Tomato selection

To provide the consumers across the world with good quality ketchup, it is extremely important to maintain consistency. Tomatoes are the key ingredient of the ketchup and needs to be carefully selected to produce consistency in taste and appearance. Manufactures are very particular when it comes to the selection of tomatoes. They prefer medium sized, firm, smooth and clear red tomatoes that have a fair acidity (Bitting & Bitting, 1915). Years of experience has shown, that a clear red variety tomato produces higher quality of lasting colours in the finished product. When it comes to tomato selection, size matters. Medium sized tomatoes often have the fewer deformities such as cracks and have more even ripening. The fewer cracks spotted on the tomatoes the better the quality as it prevents the entry of pathogenic bacteria which could cause spoilage (Bitting & Bitting, 1915). Manufacturers also check for acidity because it enriches the overall flavour as well as reduces the amount of vinegar added to the product.

Left over tomatoes

If the tomatoes need to be stored at the manufacturing plant so some time, it is important to store the tomatoes a way that prevent rotting. The tomatoes are best stored by lining the tomatoes in a create and stacking the crates in tiers with space in between each tier (Bitting & Bitting, 1915). The space allows for the circulation of air and also prevents the growth of mold which is seen during tight storage to tomatoes (Bitting & Bitting, 1915).

Washing

Washing is one of the most critical phase during processing as it ensure a clean product. Once the tomatoes have been passed the sorting stage, they are throughly washed to get rid of all unwanted particles. During washing the water pressure should be above sixty pounds per square inch. Water pressure of 100 pounds per square inch with perforations or nozzles is ideal as the it can remove adherent mold and soft rot from the tomatoes (Bitting & Bitting, 1915). Washing method required for tomatoes used for making ketchup is different than that of canning because the intense water pressure can crack the tomatoes and cause severe loss of the canning tomatoes. The inspectors approve and grade tomatoes to meet the initial requirements, therefore, good and thorough wash reduces about nine-tenths of the work for the inspectors.

Post Washing

The washed tomatoes are converted into tomato pulp using one of these three methods:

- Washed tomatoes go through grinders and into the cyclone. Cyclone is a pulping machine separate seeds, skins and stamps from the pulp.

- Tomatoes go through the scalder and then into the cyclone.

- Tomatoes are taken through jacketed-kettles and cooked until soft at 180 degrees Fahrenheit. Then the tomatoes are transferred into the cyclone.

Usually the first method produces more pulp because the tough parts are cut and ripped, squeezing more tomatoes through the sieve. A noticeable change observed in the pulp after using this method is the separation of the liquid and solid components, usually when the mixture has been siting for fifteen to twenty minutes (Bitting & Bitting, 1915). The separation of the liquid and solids (floating on the top) is caused by the air incorporated into the solids and not due to fermentation. More rapid changes are observed when the first method is used compared to the other two methods. For these reasons, manufactures usually prefer the scalder method as the pulp made this way separates slowly (three to four hours).

The next step towards getting the perfect ketchup is cooking. Tomato pulp is cooked in copper- jacked kettles that are lined with glass and have an open top. The efficiency of the open top kettle is enhanced by the strong exhaust or suction of air (Bitting & Bitting, 1915). The air moving over the kettle top will carry away the steam, thereby reducing the time of heating by ten to twenty percent. The pulp usually takes thirty to forty-five minutes to cook depending upon the equipment and consistency of the end product (Alvizienis, 2014).

Spices

During the cooking process, spices are added to enrich the flavour of ketchup up. The manufacturers may choose the spices depending on the desired favour.

Common ketchup spices

Cinnamon, cassia, cloves, allspice, mace, pepper, paprika, cayenne pepper, mustard, ginger, coriander, bay leaves, caraway and celery seed. The spices used should be purely based on the desired flavour because they do not necessarily act as preservative. The selected spices can be used whole or ground. Some manufacturers use acetic acid or oil extracts instead. Majority of them manufacturers prefer using whole spices for a high grade product. Most of the time ground cayenne is used instead of the black pepper as it seem to darken the color of the ketchup. Acetic acid and oil extracts are used only in small quantities as it can produce an undesired harsh flavour. The best grade spices will produce a high grade, bright and clean product. For the bright red color, paprika rosen or sweet paprika with less pungency is usually used. Onion and garlic are also added and the sharpness of flavour from them can be controlled by the length of cooking. The longer it is cooked, the stronger the flavour. Heinz Ketchup is made from onion powder, used in small quantity, to keep the tomato base flavour.

Additional Contents

Vinegar is added to nearly all the ketchup as it plays important role in enhancing the flavour and also acts as a preservative increasing the shelf life of the product. Addition of vinegar lowers the pH and lowers the growth of spoilage and disease causing microorganisms. Acidity is also obtained from the tomatoes when it undergoes fermentation reactions producing lactic acid. Although the addition of vinegar improves the quality of the product it is best when added near the end of the cooking process as it can attack the kettle and is usually evaporated form the boiling pulp if added to early. Usually, vinegar is added five to ten minutes prior to the end of the cooking process.

Salt is also added towards the end of the cooking process and usually in small quantities so it doesn't alter the taste of the ketchup. Salt is also capable of controlling the growth of microorganisms that may not be inhibited by the acid produced during fermentation. The acid and salt combination produces a food system that is more inhibitory to disease and spoilage causing microorganisms.

Sugar is another flavour enriching component of ketchup. Granulated sugar is added to half way through the cooking step and is the only sugar used in making high grade ketchup. Soft sugar and granulated sugar are components of low grade sugar and must be written on the label of the ketchup. Sugar is another preservative because it acts as a water binding agent, binding to free water and lowering the water activity. Sugar lowers the availability of free water and prevents the growth of bacteria and yeast in the ketchup.

Oil is usually added to prevent foaming that occurs during pulping and the amount added should be monitored carefully to prevent undesired texture and taste.

Post cooking

As soon as the ketchup is cooked, it is sent to a finishing machine specialized for removing all the unwanted solid particles such as tomato skin and bits of spice. The machine breaks up the cooked tomato mixture even further and produces a smooth ketchup texture desired by the consumers. Now the product is ready to be packaged clean and sterilized bottles.

Preservation

The main ingredient used in ketchup that serves as a preservative is acetic acid. Generally, 100-grain distilled white vinegar is used to increase the acidity of the product. The resulting tomato sauce has a pH of at least 4.6 (NSW Food Authority, 2011). This decrease in pH aids in the preservation process by creating an unfavourable environment for pathogenic (disease- causing) and spoilage causing microorganism growth (NSW Food Authority, 2011).

After ketchup is acidified, and pasteurized, it goes under a vacuum for de-aeration (Food Processing Technologies, 2014). De-aeration of ketchup prevents it from oxidizing and changing into a dark red colour (How Products Are Made, 2014). This process is therefore responsible for preserving the nice red colour and further preventing bacterial growth. Post de-aeration, the ketchup has a temperature ranging from 87-93°C (Food Processing Technologies, 2014). It is now ready for hot filling.

Hot filling is a type of thermal processing in which a product is placed in a heat stable container and immersed in boiling water or steam for a short period of time (How Products Are Made, 2014). This process controls yeasts, vegetative cells and moulds capable of creating spores (NSW Food Authority, 2011). Ideal hot filling conditions involve temperatures ranging from 90° and 95°C (NSW Food Security, 2011). The container is then sealed and inverted for two minutes before cooling.

In cases where the final container cannot withstand hot temperatures, the ketchup is put in an aseptic heat exchanger which cools it down to 32-37°C (Food Processing Technologies, 2014). The product is then pumped through tubes and into the final container or packaging.

Cooling is a significant component of the preservation process because it helps preserve the flavor. If this step is not adequately achieved, flavor loss may occur due to a phenomenon called stack burning (How Products Are Made, 2014). Stack burning results when ketchup remains at a relatively increased temperature post cooking. Cooling is most commonly accomplished by use of cold air or water (How Products Are Made, 2014).

These products are not commercially sterile; however, they are shelf stable (NSW Food Authority, 2011). To prevent deterioration of ketchup in terms of quality, color and taste, due to oxidation, the final product must be refrigerated once opened (How Products Are Made, 2014).

Packaging

Ketchup packaging has evolved over many years through the use of different materials, shapes, and the applications of packaging techniques. The traditional ketchup bottle is said to resemble that of ancient Greek vases dating back to the fifth and sixth centuries BC (Form and Function Come Together in New Ketchup Bottle Design, 2013). As packaging of ketchup expanded from glass to plastic bottles approximately thirty years ago, many approaches have been attempted to construct the most economic, time efficient, and eco-friendly method (Form and Function Come Together in New Ketchup Bottle Design, 2013).

First plastic bottle packaging approach:

Packaging plants used extrusion-blow molding, using thermoplastic material to create a multilayer container (Blow molding: Extrusion Multilayer, 2012). This structure uses polyethylene or polypropylene. In addition, poly-m-xylylene adipamide or nylon-MXD6, two common ethylene vinal alcohol polyamides are used as the layer functioning as a barrier between product and external gases (Blow molding: Extrusion Multilayer, 2012).

Second plastic bottle packaging approach:

Polyethylene terephthalate (PET) multilayer bottles were the second design of the plastic ketchup bottle packaging (Form and Function Come Together in New Ketchup Bottle Design, 2013). The condensation of terephthalic acid and ethylene glycol is used to create a polyester substance. PET packaging increases the shelf life due to its barrier against environmental microorganisms (What is Polyethylene Terephthalate, 2014). These bottles weigh 90% less than glass bottles, making them a more economic choice when shipping and can also be recycled (What is Polyethylene Terephthalate, 2014).

Third plastic bottle packaging approach:

High density Polyethylene (HDPE) packaging was the third modification to the plastic ketchup bottle (Form and Function Come Together in New Ketchup Bottle Design, 2013). Slurry is formed using Zeigler catalysts in conjunction with a low-pressure reactor, a liquid hydrocarbon solvent, and ethylene (HDPE plastic packaging, 2004). From here, the bottles are blow-molded and ready for use (HDPE plastic packaging, 2004). HDPE is commonly known to be durable, flexible, inexpensive, and resilient to the sterilization process (HDPE plastic packaging, 2004).

A new packaging method on the market:

Hot fill squeezable containers are becoming more popular as consumers are converting from HDPE to SIPA’s new design (Form and Function Come Together in New Ketchup Bottle Design, 2013). These plastic bottles are aesthetically pleasing, as they have been altered to have shorter necks on the bottle and a smoother body (Form and Function Come Together in New Ketchup Bottle Design, 2013). This shift in shape acts as a way of preventing the walls from collapsing, causing the label to crack, from pressure build up due to high temperature filling (Form and Function Come Together in New Ketchup Bottle Design, 2013). The bottles are filled with ketchup between 85-90 degrees Celsius (Form and Function Come Together in New Ketchup Bottle Design, 2013). This form of packaging is more attractive in looks as well its cost competitive prices, contributing to a more desirable design (Form and Function Come Together in New Ketchup Bottle Design, 2013).

Small packets of ketchup are also available for take out food at fast food restaurants for consumer use (Stickpack Machine for Liquid/Past Products, 2012). Stickpack Machines are designed to fill each individual packet at a speed of 70-140 packets per minute. This type of packaging is convenient for easy transportation of small amounts of ketchup (Stickpack Machine for Liquid/Past Products, 2012).

Nutritional Facts

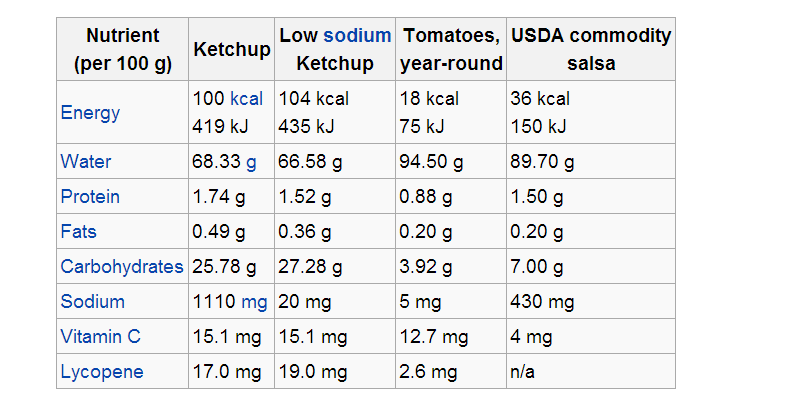

According to USDA Food Nutrient Database (2011), ketchup (catsup) belongs to the food group of vegetables and vegetable products. It is considered as a moderately healthy food. Ketchup has a very good source of vitamin C and lycopene, particularly in organic ketchup. Lycopene is an antioxidant that can help preventing some forms of cancers and lower the risk of cardiovascular diseases (Pressner, 2014). It is also very low in saturated fat and cholesterol. What needs to be aware of is that it contains high content of sodium and sugar (Wikipedia, 2014).

Summary

- Ketchup was originated from China and originally made of fish.

- Tomato based ketchup was invented in the United States after ketchup was brought to the US during the colonial period; first recipe was written by an american scientist.

- The popularity of ketchup increased rapidly in the 1870s.

- Size of tomatoes play an important role in determining the quality of the final product. Medium sized, firm, smooth and clear red tomatoes that have a fair acidity is always the number one choice.

- Acetic acid (vinegar) is the main preservation ingredient in ketchup used to decrease pH level and create and limit microbial activity.

- Ketchup must be refrigerated after opening to prevent oxidation effects on taste, colour, and quality.

- Packaging shape, size, and filling techniques have evolved over many years.

- Extrusion blow molding, PET, and Hot filling squeezable packaging are all techniques used for packaging ketchup.

- Ketchup contains lycopene which helps prevent some forms of cancer and lower risk of cardiovascular diseases.

- Consumers should watch out for the high sodium and sugar content!

Reflection

Ketchup processing and manufacturing is very thoroughly regulated to ensure consistency in the final product. Through this project, our knowledge about ketchup production, preservation, packaging and regulation has been enhanced. Knowing what goes into the food is extremely critical to prevent food-borne illness as well as for the enjoyment of food. From tomato picking to ketchup delivery, every step of the way, the manufacturers ensure quality is maintained. We now know that through the use of preservatives our ketchup has a longer shelf life and a reduced microbial growth.

Potential Exam Question

Cooling ketchup is a significant component of the preservation process because it helps preserve the ___________. If this step is not adequately achieved, the lose in _______________ may occur due to a phenomenon called _______________.

- nutrient value, nutrients, post cooling dehydration

- flavour, flavour, stack burning

- flavour, flavour, post cooling dehydration

- nutrient value, stack burning

Answer: B

Video

References

Adding Spices to Fruit and Vegetable Smoothies. (2014). Retrieved March 31, 2014, from http://www.wholeyum.com/adding-spices-to-fruit-and-vegetable-smoothies/

Avizienis, A. (2014). How ketchup is made. Retrieved from http://www.madehow.com/Volume-2/Ketchup.html#b

Bitting, A. W., Bitting, K. G. (1915). Ketchup: Methods of manufacture. Toronto: Lafayette,Bivens.

Blow molding: Extrusion Multilayer. (2012). Retrieved March 30,2014, from http://packagingtech.net/159-blow-molding-extrusion-multilayer.html

Food Processing Technologies. Retrieved March 28, 2014, from http://www.demjan.com/Food%20Processing.htm

Form and Function Come Together in New Ketchup Bottle Design. (2013). Retrieved March 30,2014, from http://www.sipa.it/en/SIPA%20ketchup%20bottle%20design

Gandhi, L. (2013). Ketchup: The All-American Condiment That Comes From Asia. Retrieved from http://www.npr.org/blogs/codeswitch/2013/12/02/248195661/ketchup-the-all-american-condiment-that-comes-from-asia

HDPE plastic packaging. (2004). Retrieved March 30,2014, from http://www.plastics.org.nz/documents/ronz-hdpe-fact-sheet.pdf

How Products Are Made: Ketchup. (2014). Retrieved from http://www.madehow.com/Volume-2/Ketchup.html#ixzz2xB87feY7

Ketchup. In Wikipedia. Retrieved March 30, 2014, from http://en.wikipedia.org/wiki/Ketchup

Matthews, C. (2013). Is tomato ketchup good for your heart? Retrieved March 31, 2014, from http://sciencefocus.com/qa/tomato-ketchup-good-your-heart

NSW Food Authority (2011). Shelf Stable Acid Preserved Foods. Retrieved from http://www.foodauthority.nsw.gov.au/_Documents/science/shelf-stable-acid-preserved-foods.pdf

Pressner, A. (2014). 9 Condiments that are good for you. Retrieved from http://www.nbcnews.com/id/35990706/ns/health-diet_and_nutrition/t/condiments-are-good-you/#.UznJv_ldUjt

Standing1. (2012). China-flag. Retrieved March 31, 2014, from http://transparentsea.co/index.php?title=File:China-flag.gif

Stickpack Machine for Liquid/Paste Products, (2012). Retrieved March 30,2014, from http://www.turpack.com/en/category/stickpack-machines/liquid-products/

Two Chums. (2012). Savvy Secrets for Vinegar -Part 1. Retrieved March 31, 2014, from http://www.twochums.com/savvy-secrets-for-vinegar/

USDA Food Nutrient Database for Ketchup. (2014). Retrieved March 30, 2014, from http://ndb.nal.usda.gov/ndb/foods/show/3594?fg=&man=&lfacet=&count=&max=25&sort=&qlookup=ketchup&offset=&format=Full&new=&measureby=

What is Polyethylene Terephthalate. (2014). Retrieved March 30,2014, from http://www.wisegeek.com/what-is-pet-polyethylene.htm

Wheeler, A. (2014). Pantry Essentials: All About Ketchups. Retrieved March 31, 2014, from http://www.seriouseats.com/2014/02/pantry-essentials-all-about-ketchup.html

Xinhua. (2011). Your Ketchup Probably Came from Xinjiang. Retrieved March 31, 2014, from http://www.farwestchina.com/2011/08/your-ketchup-probably-came-from-xinjiang.html

|

|