Course:FNH200/2013w Team09 PotatoChips

Lay's Classic Potato Chips... Betcha can't eat just one!

Team 09's project investigates the journey of the standard potato as it goes through its transformation into a delicious snack food. We delve deeper into the idea of how using just 3 simple ingredients, as advertised by Frito-Lay, could be the secret behind creating a continental favourite in their Classic potato chip.

We also take an inside look at the manufacturing procedure employed since the very beginning of mass-produced potato chips, pondering the differences in steps between the stereotypical Lay's potato chip and their reduced fat variations. Over the years, we have naturally been influenced by their marketing strategies, feeling enticed by their product, as an appealing option, so logically, there must be new processes, waiting to be analyzed.

Next, our focus shifts to the bright yellow packaging and how something so simple could mean the difference between a quality chip and a crumbly afterthought. The visual appeal of the exterior is only one of the many aspects that we subconsciously take in, where the snack food product within must meet the expectations of our taste buds, so the technology employed must be top-notch.

In this day and age, no commercially prepared food product is safe from nutritional scrutiny, and Lay's Classic potato chips are no different. The Nutrition Facts panel displayed on each food product provides an easy to understand table with 13 core nutrients and calories as everybody's reference guide. This allows us to compare the Classic potato chips' caloric content with similar products, weighing in on its role in our diets.

With that in mind, we look at the notable health concerns and benefits, over the last couple of years, that have tarnished the company’s name and how they have now resorted from continual use of chemical substitutes, moving forward in a more positive light, by incorporating various manufacturing patents to create a healthier chip product.

When it's all said and done, we understand that Western society doesn't dictate the choices of an entire world, so we shed some light on cultural differences and how they will always play a part in our dietary choices, capping off our entire project with a look at potato chips from another point of view.

Introduction

What Is a Potato Chip?

The origin of North America’s favourite snack food is actually unclear, as there are many renditions of a very similar beginning. However, we will focus on the most famous story of them all and how the potato chip came into fruition. It originated in Saratoga Springs, New York, in the outskirts of New England, where this delectable snack was created by accident, out of sheer frustration, by George Crum [1], and as a result, this creation was dubbed the Saratoga Chip, taking on the namesake of its birth place.

Delving deeper into the story, we find that in 1853, a patron at Moon’s Lake House claimed that his fried potato dish wasn't crunchy enough and even showed signs of being soggy, so even after repeated attempts of trying to “satisfy” the clientèle's endless demand, Crum broke down and sliced each potato paper thin, fried and doused them in extra salt, as an act of rebellion against the clientèle's stipulation. [2] Ironically, this sudden stroke of culinary pique turned into a customer favourite, with requests pouring in once the news spread about this browned, paper-thin potato treat.

The thin fried potato crazy began to spread all over America in the late 1880's, with the idea of revamping this snack food into a grocery store product, with Cleveland's William Tappendon starting to make potato chips in his kitchen and delivering the famed chips to look establishments, eventually transforming his rear barn into a make-shift factory as the customer demand increased, as one of the first of its kind in the country Cite error: Invalid parameter in <ref> tag, in 1895.

According to the the US Food and Drug Administration, filed under CPG Sec. 585.710 [3], the definition of potato chip is "thin slices of potatoes fried in deep fat", with the ingredients including, and not limited to, type of shortening to be used as the frying medium, salt and choice seasonings, anti-oxidants, preservatives - ascorbic acid, sodium bisulfite, sodium phosphate, emulsifiers and dextrose to help control the browning of chips.

Are Pringles Classified As Potato Chips?

Unfortunately, Pringles branded, as well as other similarly marketed potato and wheat-based stackable snack chips are not considered a "potato" chips per se, as they failed to meet the criteria required to be classified as such. After numerous manufacturers objected Pringles' claim, the US Food and Drug Administration stepped in with the final verdict, ruling that the Pringles product was only composed of 42% potato along with a combination of potato, corn, and rice flour and wheat starch.[4]

However, with that notion, potato and wheat-based snack chips are very similar to traditional potato chips in ingredients, mouthfeel and texture, as well as the manufacturing process, where the individual chips are fried [5], not baked, contrary to popular belief, with its savoury texture playing a large role in this assumption.

Frito Lay

History

Herman Lay found him in the midst of the potato chip industry as a travelling salesman for the Barrett Food Company, peddling his stock from the back of his Ford Model A. Soon, his marketing territory grew exponentially, making it sensible to take out a loan for $100 USD to found the H.W. Lay Distributing Company based out of Atlanta, Georgia, which was an distributing extension of Barrett's. [6] His company serviced from Atlanta to Nashville, Tennessee, bringing the golden, delicious snack Northwest-ward. A while later, a representative of the Barrett Food Company offered to sell the manufacturing plants in Atlanta and Memphis to Lay, where they struck an agreement for the company through a deal involving cash and the difference in preferred stock. [6]

With his continued success in the snack food industry, he merged with The Frito Company in 1961, simultaneously creating the largest snack food company in the United States, known as the Frito-Lay corporation. [7] A couple years later, in 1965, he merged with Pepsi-Cola to create PepsiCo Inc. [8] Their company is the household name in the States, standing atop the snack food industry many years later, as the Lay's brand is still America's premier chip choice. [9]

Lay's Classic Potato Chips

Ingredients and Functions

Ingredients

A typical plain bag of Lays potato chips is advertised by Frito Lay that it only includes 3 main ingredients - potatoes, sunflower, corn or canola oil and salt. [10]

Depending on the type of flavour of the potato chip, there are more ingredients included. For example, the barbecue flavoured potato chips include: sugar, dextrose, salt, malted barley flour, torula yeast, molasses, maltodextrin, natural flavours, spices, paprika, cornstarch, tomato powder, garlic powder, yeast extract, onion powder and paprika extract)

However, though they claim themselves to be a healthy natural, food additive-free snack, not all of their products are additive free. They have a small disclaimer section written on their website saying " Only the regular flavor (no seasoning or flavor added) of these products is additive-free. There may be flavored varieties of these brands that do contain additives, as stated on the product labels." [11]

Functions

Potatoes: The root vegetable that the snack food is made out of

Sunflower, corn or canola oil: Used to fry the sliced potatoes and make them into chips

Salt: Used as flavouring to give the salty flavour

General Potato Chip Manufacturing Procedure

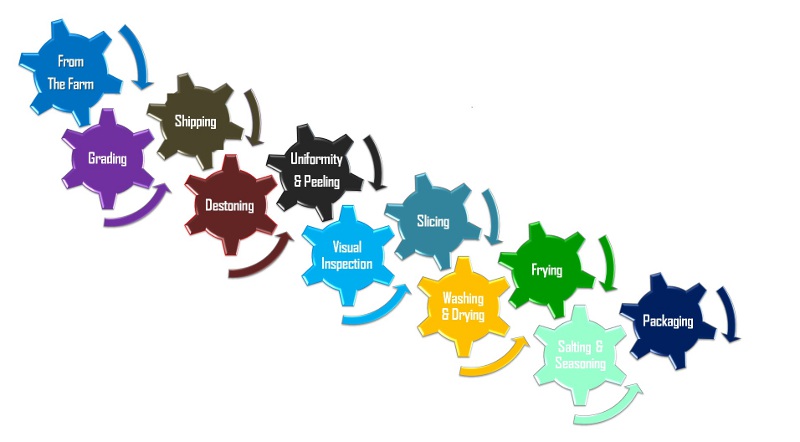

Each potato chip company has their own method of producing the final product, altering from the time spent in the fryer, to the application of the salt and seasoning and minor modifications throughout. However, they all follow the same general practices listed below to ensure their product is competitive in the marketplace.

Frito-Lay

Frito-Lay follows a 11 step process - 9 in-house (though advertised as 5 combined steps) [10], and typically take about 15-20 minutes [12] to convert the raw, freshly rooted potato into a flavourful snack. They have since patented and revised various oil reducing processing methods to create reduced oil traditional and kettle potato chips, discussed later on in the page.

From The Farm:

- The potatoes are taken directly from the farmers' plots or from dark room storage, depending on the seasons. For North American chip production, various growing regions feed processing facilities, ranging from the Florida area for Spring, moving into North Carolina, Missouri and Indiana as we enter the Summer months. The peak of the harvest in August comes from the field of Michigan and Wisconsin. Generally, the field potato season start from May 1st through to October, whereas November to April, the companies rely on their storage potatoes.

Grading Process:

- In the grading process, each potato is inspected for rot, green heads and spots, and an array of other defects and harmful diseases. Once they successfully pass inspection, they continue on their journey to the processing plant. Potatoes that are sold and used for processing still follow the Canadian Food Inspection Agency's Grades - Canada No. 1 and Canada No. 2 [13] or the U.S. Department of Agriculture's Grade and Size Standards - Extra No. 1, No. 1, Commercial and No. 2 [14].

Shipping:

- Trailers containing tonnes of loosely transported potatoes are loaded onto an elevated platform, where the hydraulic landing angles the trailer, allowing the spuds to roll down onto a metal conveyor belt leading them to numerous storage tanks, each capable of housing approximately 50000 lbs/4500 kg.

Destoning:

- The is known as the initial step in the processing phase, where the potatoes slowly flow from the storage facilties into a large hopper connected to the in-line destoner, filled with fresh water and a spiral auger, gduing the freshly washed and rinsed potatoes into an automated peeler. Naturally, the destoner lives up to its name, as their main function is to remove all the stones, wood, and other foreign material that may have travelled with the potatoes on-route to the processing plant. The removal of the foreign material helps to prevent damage to the other machinery down the line.

Uniformity and Peeling:

- 23 or more abrasive rollers that revolve at a constant speed makes up the peeler employed by the manufacturing companies. These rollers help to ensure that each potato that pass by are peeled properly. Next, they slide through gauged gaps, with the smaller potatoes falling through, while the larger spuds continue to greet an automated blade slicing vertically to ensure all the potatoes are of equal size.

Visual Inspection:

- Trained human inspectors line the following conveyor belt, who provide the final decision on which potatoes can continue, while removing problematic ones, to be composted or remade into animal feed.

Slicing:

- In order to produce crispy potato chips, each potato is sliced into very thin slices, as they are fed by another hopper against adjustable slicers. Depending on the style and brand, they can take on many shapes and thickness.

Washing and Drying

- Post-slicing, the potato slices are added to a submerged rotating mesh drum and conveyor belt filled with fresh water, washing and rinsing them, while removing excess starch built up from slicing. They are machine-blown dry upon entering into the fryer.

Frying:

- This is the main component of a successful potato chip, as the manufacturer's frying kettle is filled with (or a combination of) sunflower, corn and/or canola oil [15], which is heated to temperatures between 330 - 360°F/180°C [16]. Stainless steel paddles are attached to the kettle to propel slices forward through the machine, submerging each into the oil along the mesh conveyor for about 3 - 4 minutes [16]. After exiting the fryer, line operators ensure each chip is up to standard while optimizing operating conditions.

Salting and Seasoning:

- Depending on the flavour produced, the partially finished product goes through the flavouring stage. They are either coated with a blend of spices and seasoning - made from all natural components or simply in salt - creating the original flavour that North American consumers have been accustomed to for many years. Passing through the rotating seasoning drums, they receive their fair share of the mixture and fall onto another conveyor. This belt vibrates to allow for the excess seasoning to shake off, while employees simultaneously visually inspect the finalized product, removing pieces that have failed the company's quality control standards.

Packaging:

- Bucket lifts greet the potato chips at the end of the inspection belt, where they slide batches of potato chips into automated packaging machines. To accommodate large demands, the machine can feature upwards to 8 packagers, collecting vibrated chips into a scale, opening the trap door once the programmed weight has been achieved, loading product into the partially-sealed bag waiting below, sealed as the next bag is formed.

- Once inside the specially designed bag, they proceed to the boxing stage, either conducted manually by employees or automated packers. One advantage with human packers is the ability to physically verify each bag weighs appropriately the same in comparison to the others. Each lot of potato chips are packed into corrugated boxes and palletized for distribution and storage.

Exclusive look into Frito-Lay Factory 43 servicing the United States of America (Northeast Region)

Extended Look Into Deep Fat Frying

Deep fat frying takes the concept of shallow frying to another level. Each food particle destined to be fried is completely immersed into a cast-iron or stainless steel vessel holding the boiling oil. The difference between home and commercial applications is the use of a wire strainer or a mechanical conveyor beneath the fryer to control the overall amount of oil used primarily as the frying medium, to ensure the minimal safe internal temperature has been met, [17] and the saturated oil that penetrates into the chips due to long exposure in hot oil. The use of deep fat frying originates from the primary functions of cooking oils, as they lubricate both the manufacturing and food particle surfaces, improve the friction coefficient between the two entities, and reduce the cooking time, while providing adequate flavour without additional additives and seasonings. [18]

If this process is administrated correctly, the final product isn't as unhealthy as the general consensus. The main concept behind deep fat frying is to ensure the frying oil is hot enough, allowing the food particle to be submerged for a reduced duration. The business standard cooking temperature is approximately 330-360°F/185°C. [18] The high temperature of the oil causes the water within the cavities of the potato slices to evaporate rapidly, subsequently picking up oil as the slices dehydrates. In turn, this entire process actually steam cooks the individual slices and naturally will not penetrate inside, under the correct circumstances. The steaming process can be explained through the action of heating the water to a certain degree, where the oil no longer has the ability to go against the direction of this powerful flow, as the water vapour pushes the bubbles toward the surface. [19] However, if the food particles are submerged in the hot oil for extended periods of time, the oil will penetrate into the crevices, leading to a greasy and saturated product, influencing the unhealthy notion.

Reduced Fat Potato Chip Manufacturing Procedure

More often than not, people want to be able to enjoy the unique taste of potato chips while not consuming the large amount of fats that come with them. Scientists and food manufacturers have come up with a few methods on reducing the amount of fat in potato chips.

Reduced fat or low fat potato chips generally have a lower fat content than regular chips. Depending on the brand of potato chip, these chips can contain between 20 and 60 percent less fat than the original version [20]. For instance, one serving of Baked Lays potato chips has only 2 grams of fat, while one serving of Lays Original chips contain 10 grams of fat, and Kettle Cooked Lays potato chips hold 6 grams of fat.

Cooking Process

Regular potato chips are often deep-fried in hot cooking oil that has reached a temperature of 350-375°F/177°C [21]. Manufacturers can reduce the fat content of potato chips in one of four ways. Most of these methods involving baking, because baking has the ability to cook food without much use of oil and can replicate the crispy texture in foods that deep-frying creates. The first method completely avoids the process of deep-frying. It involves baking, oiling, and salting slices of potato [22]. Potato chips prepared this way generally contain 3 grams of fat per serving. Another process takes sliced potatoes, quickly fries them, and then removes some of the oil they picked up during frying by steaming and baking [22]. This method of cooking potato chips will result in 6 to 7 grams of fat per serving. Note that the fat content reduction in this method of cooking is not too significant, due to the fact that the potato chips are still being fried. Potato chips can also be kettle-cooked, where the amount of oil used in frying is barely enough to cover the surface of each potato chip. The cooking temperature starts off low, and is then slowly increased to 177°C [22]. This results in less oil being absorbed by the potato chips, but they only contain around 2 grams less fat than deep fried potato chips. Finally, some reduced-fat chips are made by combining sugar, binders, and leaveners with dehydrated potatoes to form a dough, which is cut into “chips” and baked [22]. These chips have between 1½ and 3 grams of fat per serving.

Olestra

Although some cooking process allow the reduction of fat in potato chips, the same types of oils are being used to cook these low fat potato chips and regular potato chips. Recently, there has been chips that are made with a fat substitute called Olestra. The benefit of deep frying potato chips with Olestra is that the chips will contain absolutely no fat. Olestra contributes 0 Calories to any diet because it cannot be broken down in the human digestive system, and passes through the gut. There's some controversy surrounding Olestra, however, because some individuals react sensitively to it and can experience loose bowels from ingestion. This is the main reason why Olestra has not been approved for use yet in Canada. In the United States, the Food and Drug Administration approves of the use of Olestra and potato chip manufacturers continue to use it despite its negative effects on the bowel [21].

Packaging

Potato chips were originally prepared in a kitchen and immediately sold. [23] The shelf-life was very short. Potato chips were packaged in barrels or tins, which crumpled the chips and made them stale.[23] However, in 1925, the automatic potato-peeling machine was invented and a year later, Laura Scudder’s potato chip company ironed sheets of waxed paper into bags. [23] [24] The chips were hand-packed into the bags and ironed shut. These inventions paved the way for mass production. Today’s potato chips packaging has four main goals: to keep out oxygen, to keep out moisture, to keep out light, and to prevent the breakage of the chips. Most potato chip manufacturers use packaging materials that are a composite of paper, plastic film, and foil. Sealed plastic bags with a foil interior lining and tubular paper-board cans with a foil-lined interior and a resealable plastic lid are the two major forms of potato chip packaging.

The Science Behind The Packaging

Proper packaging of the chips is essential for maintaining their quality. Nitrogen flushing is done to chip bags to prevent the lipid oxidation of chips, which is responsible for making chips go stale. Oxygen is very reactive, often causing chemical changes to take place. Thus, when processed food is exposed to Oxygen, the oils go rancid, chips become discoloured and food spoilage occurs. On the other hand, Nitrogen is stable and unreactive, so a Nitrogen environment is good for storing foods that oxidize quickly. Nitrogen allows the chips to stay fresh longer while leaving the flavour or texture of the chip unaffected.[25] Therefore, the bag is deoxygenated by being blasted with nitrogen gas before sealing. Polyethylene terephthalate (PET) is commonly used as a major layer in the bags due to its low permeability to nitrogen gas and its ability to work with high speed packaging machines.[26] The packaging also prevents the breakage of chips. For example, the Nitrogen filled bags protect the chips by providing extra cushion and the can allows chips to be stacked neatly, thus preventing breakage.[23] [27] The packaging also acts as barrier to the moisture in the air, preventing the chips from becoming soggy and reducing the rate of oxidation. Water activity levels affects the rate of lipid oxidation. Lipid oxidation is lowest around around 0.4 aw, and increases as you increase or decrease from that level.[28] Therefore, the packaging controls the amount of moisture that is allowed in the bag. Lastly, the opaqueness of the packaging blocks the chips from light exposure, thus preventing the occurrence of photodegradation. [26]Light is a form of radiant energy, thus prolonged exposure to light sources such as sunlight will cause foods to undergo chemical reactions, causing deterioration. [29]

The Packaging Process

The finished chips are taken to a packaging machine. The pre-set weight of chips is measured and a metal detector checks for foreign material. The bags forms, which allow the chips to fall into the bag. Nitrogen fill the space in the bags and heat seals the bags. The sealed bags are hand-packed into cartons. For the packing of chips in cans, the chips flow down a chute into the cans and a lid is then attached to each can. [23]

Nutritional Value

Caloric Content

Potato chips are often categorized into the calorie dense section of foods. One ounce of potato chips, typically consisting of 15-20 chips, can easily contain 154 calories and 10 grams of fat [30]. From previous lessons of FNH 200, fats are known to provide 9 kilocalories per gram. With some simple math, we can estimate that around 60 percent of the calories in potato chips come solely from the fat that is used to deep fry them. The rest of the calories come from the potatoes that are used in making the chips. Potatoes mainly consist of carbohydrates in the form of starch, a common polysaccharide found in plants. The starch, or carbohydrates, makes up for 35 percent of the calories in potato chips [31]. The trace remaining calories come from protein in either the potato or frying oil.

Frying Oils

Most potato chips today are deep fried in either sunflower, corn or canola oil, all of which are a good source of omega-6 fatty acids [32]. Typically, foods today are fried in these vegetable oils because it is the inexpensive category of the oils available that will not create rancidity when cooked in high temperatures or readily exceed their smoke points. An oil that has passed its smoke point will exhibit signs of rancidity which include foul odour and taste as the oil naturally starts to break down. [17]

| Type of Oil | Approximate Smoke Point [17] |

|---|---|

| Peanut, Safflower, Soybean | 450°F |

| Grapeseed | 445°F |

| Canola | 435°F |

| Corn, Olive, Sesame Seed, Sunflower | 410°F |

One concern that stems from high omega-6 fatty acid consumption is the increased risk of inflammatory diseases, which include type 2 diabetes, auto-immune disorders, asthma, and cancer [32]. These diseases arise when omega-6 fatty acids are consumed in much larger amounts than omega-3 fatty acids.

Potato chips, like any other fried foods, have a high fat content due to the cooking process of deep frying. A diet consisting of high fat intakes will most likely lead to weight gain, obesity, and cardiovascular diseases. Deep fried potato chips have a high fat content, making it a snack that should not be consumed too often. If you regularly include chips as part of your diet, you may not be consuming as many nutrients as you should. Chips are typically low in vitamins and minerals, and they tend to displace things in the diet that are higher in nutrients.

Health Benefits and Concerns

Oil Reduction Manufacturing Process Patents

Reduced Oil Potato Chip Process

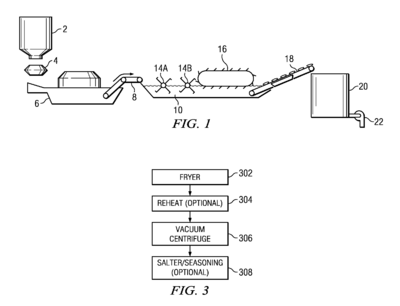

Recently, in January 2014, Frito-Lay North America successfully patented a new reduced oil potato chip process, described as a low pressure processing method by their designers, which would be ideal in manufacturing a reduced oil potato chip product with high consumer demand. [33] According to the Frito-Lay spokesperson, the main component of the low pressure frying and deoiling reduces the overall content of oil in the finished snack food product. This is the exhibited result of a process that incorporates differential pressures throughout the manufacturing steps, which is key in helping to improve oil reduction. Cite error: Invalid parameter in <ref> tag

In the patented process, each potato slice is fried in hot oil, with temperatures reaching between 320 - 380°F/160-194°C in atmospheric pressure, found in each form of production employed by Frito-Lay – Continuous, Semi-Continuous, Batch and Semi-Batch-Styled Frying. The deoiling step is administrated when the potato chips are done frying, where they are added into a vacuum centrifuge set to a lowered pressure, as “food pieces [that] have been previously fried at atmospheric pressure and then subjected to a low pressure centrifugation” showed results of surprisingly dramatic reductions in oil content, compared to the previous use of just atmospheric centrifugation, explained by Frito-Lay.

This phenomena can be explained through science as it spurs from the theory that the vacuum action draws out oil from the interior cavities of each potato slice onto the surface allowing the centripetal force to naturally wick it away. Additional, because of the positive pressure differential present between the spacing of each slice, a result maintained by the vacuum, this further resists oil absorption during the centrifugation step.

Technology Slashes Oil Content By Third

Before the New Year, in December 2012, Frito-Lay North America filed for an international patent [34] for a manufacturing system designed to reduce the overall amount of oil found in both the final products of their traditional and kettle potato chip varieties. The results from the now patented (March 2014) system help create processed potato chips with the final oil content of less than 18% in weight, which is assuring given that kettle chips produced by Batch-Frying consist of 30% oil content, whereas the traditional chips produced by Continuous-Frying held oil content ranging between 34-38% in weight. [35]

The overall patent covered the three-part process – Pre-Treatment, Fryer Treatment and Post-Treatment. [36]

- The Pre-Treatment consisted of the “hot potato” method, which involved the submersion of whole-peeled potatoes in hot water ranging between 130-140°F/54-60°C, where Frito-Lay claimed that the method reduced the oil content by gelatinizing starch which alters the potato’s pectin structure, as the matrix is shift to the surface of the sliced potato hindering oil from permeating into the potato slices during frying.

- The Fryer Treatment involved manipulation of the temperature-time profile in the fryer, as the designers found that the oil content may be reduced through a steep, faster temperature drop when the slices enter the fryer. After the initial drop, there is an opportunity for the slices to be exposed for about 3 -8 minutes in a new temperature range of 220-260°F/104-127°C, which is slightly longer in comparison to the traditional manufacturing technique.

- The Post-treatment method uses a superheated steam at 300°F/149°C as an act to further reduce the oil content. The superheated steam method, in accordance to Frito-Lay, does not have any drawbacks of other post-treatments, which include residual and saturated steam, which in turn increases the moisture content in the potato chips.

Olestra Controversy

In the late 1990s, Frito-Lay introduced an Olestra-enhanced potato chip product, marketed under the WOW! brand [37], with the aim of manufacturing a snack that provided the same satisfaction as its traditional counterpart. However, the consumer’s dream of the perfect snack ends at the fact that Olestra isn’t metabolized by enzymes, leading it to be unabsorbed by the body. Despite achieving attractive results, producing 0 fat and only 75 calories in an ounce of WOW Chips, compared to 10 grams of fat and 150 calories of the traditional chip, the post-consumption result mirror that of a laxative, where stomach cramps and diarrhea reigned. [38] Products containing this sucrose molecule with long-chain edible fatty acids are required to have a label on their respective packaging, stating that it contains Olestra along with the additions of vitamins A, D, E and K. The additional fat soluble vitamins are present as Olestra inhibits the absorption of these vitamins and carries them through the consumer “unchanged”. [39]

In spite of making over $347 million in sales, the back-lash of the media and their take on the objectionable side effects tarnished the Frito-Lay company name, where consumers were weary of continuing to support the products, dropping sales to $200 million by the year 2000. From this poor publicity and the recent US Food and Drug Administration requirement changes, Frito-Lay re-launched the Olestra-enhanced product under the “Light” sub-brand in 2004, with speculations that they reformulated the recipe, though Olestra is still listed in the ingredients. Frito-Lay along with other snack food companies were no long required to post warning labels on these specific products. This lead to The Center for Science in the Public Interest to issue a warning that this sucrose polyester had returned to the market and consumers should be conscientious of their dietary choices. Once again, in hopes of restoring their name in better light, spokeswoman Aurora Gonzales insured consumers that their products and packaging were compliant with all federal requirements but will make minor changes to prominently display the Olean logo and banner, making it easier to recognize the products made with Olestra. [40]

Potato Chips in Society

Potato Chips' Contextual Use In Society

We will be looking at potato chips and their influence in different societies and cultures. Potato chips are commonly served as appetizers, side dishes or as a snack food product. They make up the dominant part of the snack food industry in Western societies, which makes sense as they were invented in the United States of America. In our society, potato chips are generally viewed as junk food, which can lead to unhealthy lifestyles when consumed in excess. According to the American Society for Nutrition, high amounts of potato chips provide high levels of Acrylamide, which have adverse changes in oxidized low-density lipoprotein (LDL) which is also known as bad cholesterol, increasing inflammatory markers, all the while eliminating antioxidants that usually helps our body remove the Acrylamide. All this, in turn, will lead to an increased risk of heart disease and thus seen as hazardous, in the public eye, when they are consumed out of moderation.[41]

Different Flavours of Potato Chips In Different Cultures and Societies

Not surprisingly, around the world, there are a variety of different flavours of potato chips. These flavours are the direct reflection of traditional foods of these countries, which in turn cater to the preferences of the societies within.

| Country | Dominant Flavour [42] |

|---|---|

| Australia | Vegemite |

| Brazil | Queijo Coalho |

| China | Numb and Spicy (Hot Pot) |

| India | Magic Masala |

| Mexico | Adobadas (Chili Pepper Combination) |

| Russia | Red Caviar |

| South Africa | Spring Onion and Cheese |

| Spain | Gambas al Ajillo (Spanish Prawn Tapas) |

| Thailand | Nori (Seaweed) |

| United Kingdom | Pickled Onion |

| United States of America | Classic |

Additive Nature of Potato Chips

According to various studies conducted to try and explain the addictive nature of potato chips, they state that a possible reason may come from the revelation of naturally higher level of Fat and Carbohydrate content, which follow the ideas of our ancient ancestors, who generally had a normal tendency to be fairly attracted to the idea of foods that yielded a higher energy supply. Clearly, they played off the idea of having more energy meant increased productivity. This hypothesis is supported by research conducted on laboratory rats that were presented with potato chips alongside Rat Chow; both with similar nutritional content, and the rats still preferred the potato chips. Research speculation explained this trend with the idea of chips providing another substance that caused stimulation of the reward, addiction, food intake, sleep, activity and motion centres in their brains to heighten.[43]

Video Presentation

Team 09's project investigates the journey of the standard potato as it goes through its transformation into a delicious snack food.

"The Front Page" covers various topics including:

- Controversy and Patents

- Nutritional Aspects

- Cultural and Social Differences

- Ingredients and Functions

- Science Behind The Packaging

We hope you enjoy our take on potato chips!

Reflection

As a collective group, we live in a society that has always been influenced by potato chips in one form or another, where the product takes on many roles outside Western society. Due to their addictive nature, we typically mentally disregard the negative effects, especially if we live a reasonably healthy lifestyle, treating it as a guilty pleasure rather than a serious health risk. With this notion, our previous understanding of a single bag of potato chips was strongly influenced by culture, dictating our positive and negative thoughts, overriding the true process of this delicate snack. The result of this project allowed us to dig deeper into this Western staple and uncover a better understanding.

We were able to gain a greater understanding of what it means for a potato chip to be classified as a potato chip rather than a potato snack, while going into depth about the manufacturing process and how it has changed dramatically since the start of mass-produced chips more than a century and a half ago. Keeping the chips fresh, flavourful and in good condition required the investigation of the science behind the packaging, both in the plastic bag and paper-board can forms. The Nitrogen flushing process was briefly covered in as an extension of Modified Atmosphere Packaging, so with that in mind, we were able to grasp the overall concept of the de-oxygenating our packages and replacing the interior cavity with a less reactive molecule, doubling as a cushion for the fragile chips.

Large companies are easy targets for scrutiny, one way or another, but there were concerns raised by various institutions that required them to rethink their marketing and manufacturing practices, including the reduced use of Olestra-based products, while venturing into creating systems that require less oil in order to make the same product. The US and international patents filed by Frito-Lay was a positive step forward, with the notion in mind to explore different avenues of reducing oil content rather than employ substitutes that have negative repercussions. We delved deeper into the advertised simplicity of Frito-Lay chips, only to find a loophole in their words, as they displayed a disclaimer on their official website to list their Classic potato chips as the only version made with “3 simple ingredients”, while the others carried the notion of various other additives and seasonings. There is a general consensus that the consumption of potato chips regularly would negatively influence your body. This claim is true per se, though it depends on whether your primary caloric intake is from deep fat fried products or if these products are enjoyed in moderation. The choice and reasoning of frying oils employed explained part of the negative influences over an elongated period of exposure, creating an imbalance of Omega-3 and -6 Fatty Acids as well as an increased risk of obesity and various diseases, furthering the negative conception of potato chips.

Conclusion

Starting off as a branch of a small industry based in Atlanta, Frito Lays has become a top choice potato chip brand in North America and throughout the rest of the the world. Advertising their primary product as using just three simple ingredients allowed them to be viewed as a company passionate about creating healthier products and one which cares about their consumers’ dietary choices. However, like most guilty pleasures, we need to remember that potato chips, regardless of variety, must be eaten in moderation, as part of a balanced diet. A quality potato chip package ensures its four main goals are achieved - to keep out Oxygen, light, moisture, while preventing the chips from breaking. Introducing techniques such as Nitrogen flushing within foil lined plastic bags allow us to enjoy these tasty and crunchy chips. In light of controversy and health concerns, Frito-Lay has implemented ideas to reduce their use of chemical substitutes in their food products, opting to patent new technology to reduce the oil amounts used in manufacturing, a reassuring step for informed consumers. While Deep Fat Frying will continue to be the main component of manufacturing potato chips, we understand that the duration that the potato slices remain submerged under the oil plays a large part in regulating the penetration and absorption of the frying medium. We also need to consider the oil(s) we choose to administrate our frying with various smoke points to reduce the chance of creating rancidity. With the reduced fat variations, we grasped the idea of adding additional steps - baking, kettle cooking, as means of replicating the crispy texture without the repeated use of Deep Fat Frying. Finally, an incorporation of different social points of view allowed us to understand the role of potato chips within other cultures, while linking heightened brain activity and motion centres to a globally recognized additive nature of a browned, paper-thin potato treat.

Exam Question

Taking into consideration the packaging techniques used by potato chip companies, we often find our favourite flavoured chips in a _____(a)_______ Atmosphere Packaging. This type of storage allows for optimal conditions where _____(b)_____, the more reactive gas is directly replaced with ____ (c)______ flushing, _______(d)________ the bag to prevent oxidation. Moisture, on the other hand, affects the rate of ____(e)_____, while light causes _____(f)________.

| Answer Choice | (a) | (b) | (c) | (d) | (e) | (f) |

|---|---|---|---|---|---|---|

| A | Controlled | Nitrogen | Oxygen | De-oxygenating | Reaction | Photodegradation |

| B | Modified | Nitrogen | Oxygen | De-nitrogenating | Oxidation | Photodegradation |

| C | Modified | Oxygen | Nitrogen | Oxygenating | Reaction | Retrodegradation |

| D | Modified | Oxygen | Nitrogen | De-oxygenating | Oxidation | Photodegradation |

| E | Controlled | Oxygen | Nitrogen | De-oxygenating | Oxidation | Retrodegradation |

Answer is (D)

Taking into consideration the packaging techniques used by potato chip companies, we often find our favourite flavoured chips in a Modified Atmosphere Packaging. This type of storage allows for optimal conditions where Oxygen, the more reactive gas is directly replaced with Nitrogen flushing, De-oxygenating the bag to prevent oxidation. Moisture, on the other hand, affects the rate of Oxidation, while light causes Photodegradation.

References

- ↑ George Crum: Inventor of Potato Chips George Crum - Inventor of Potato Chips

- ↑ History of the Potato Chip Kitchen Project's Take

- ↑ U.S. Food and Drug Administration, U.S. FDA - CPG Sec. 585.710

- ↑ BBC News: Pringles 'are not potato crisps', BBC News - Pringles "are not Potato Crisps"

- ↑ The New York Times: Business Day The New York Times - Once a Great Flop, Now Sold for Billions

- ↑ 6.0 6.1 Herman W. Lay Herman Warden Lay

- ↑ Frito-Lay Quick Facts Frito-Lay Quick Facts - History

- ↑ PepsiCo: Our History PepsiCo - Our History (1965)

- ↑ Frito Lay:Our History Frito Lay's Collaboration

- ↑ 10.0 10.1 Frito-Lay: Simple to Make, Frito-Lay - Simple to Make in 5 Steps

- ↑ Frito-Lay North America U.S. Products Not Containing Additives

- ↑ Ballreich's Total Time Needed

- ↑ CFIA: Potatoes CFIA - Potatoes (Fresh Fruit and Vegetable Regulations)

- ↑ USDA: Potatoes USDA - Potato Grades, Sizes and Packaging

- ↑ Frito-Lay: 3 Simple Ingredients, Frito-Lay - 3 Simple Ingredients

- ↑ 16.0 16.1 Funzug.com: A Look Inside Pepsico Funzug - How Lays Are Manufactured

- ↑ 17.0 17.1 17.2 USDA - Food Safety Information Food Safety Information - Deep Fat Frying and Food Safety

- ↑ 18.0 18.1 Deep Fat Frying UK Primary Functions

- ↑ Eat Out Zone Cooking Techniques - Deep Frying

- ↑ Are Kettle Chips Really Healthier?

- ↑ 21.0 21.1 Difference between regular and low fat potato chips, Cooking temperature.

- ↑ 22.0 22.1 22.2 22.3 Reduced fat potato chips, Methods of reducing fat in potato chips.

- ↑ 23.0 23.1 23.2 23.3 23.4 Made How, Made How -Background.

- ↑ Laura Scudder, Laura Scudder - Our History.

- ↑ Moment of Science, How Do Potato Chips Stay Fresh In The Bag?.

- ↑ 26.0 26.1 Potato Chip Economics, Packaging.

- ↑ Brandstoke, Pringles - When The Packaging Is The Brand.

- ↑ Water Activity, AW -Lipid Oxidation.

- ↑ Food Safety Site, Different Ways That Food Spoils: Light.

- ↑ What are the negative effects of potato chips?, Weight gain and low nutrition.

- ↑ Food database calorie counter, Macronutrients of potato chips.

- ↑ 32.0 32.1 How too much omega-6 and not enough omega-3 is making us sick.

- ↑ Google Patents (US20130022719A1) - Low Pressure Deoiling of Fried Food Product

- ↑ PatentScope(WO2012170523)-Method For Reducing Oil Content of Potato Chips

- ↑ Bakery and Snacks R&D - Technology Slashes Oil Content By Third

- ↑ Food Business News Research - System Reduces Oil In Potato Chips

- ↑ MNN: Famous Food Flops Famous Food Flops - WOW! Chips

- ↑ Fast Company FC - What Were They Thinking?

- ↑ Fat Substitutes Fat Based

- ↑ The Washington Post: Voices Voices - No Longer Making Light of Olestra

- ↑ Science DailyAdditional Evidence That Potato Chips Should Be Eaten Only In Moderation

- ↑ PepsiCo PepsiCo - Different Flavours of Potato Chips around the world

- ↑ Softpedia Softpedia -Science Explains Why Potato Chips are so Addictive

|

|