Course:FNH200/2013w Team04 PeanutButter

Introduction

PB&J, peanut butter cookies or simply straight out of the jar with a spoon: most of us have grown up knowing and loving this delicious, gooey treat, but we are far from experts on the scientific principles behind it. Why are there so many kinds of peanut butter, and how are they all made? What is the difference between natural peanut butter (non-hydrogenated peanut butter) and hydrogenated peanut butter? What are the purposes and benefits from using some ingredients instead of other ones? How is peanut butter made? What are some health concerns associated with peanut butter? Are there any safety concerns? These are some of the questions that we will explore and address in our research project.

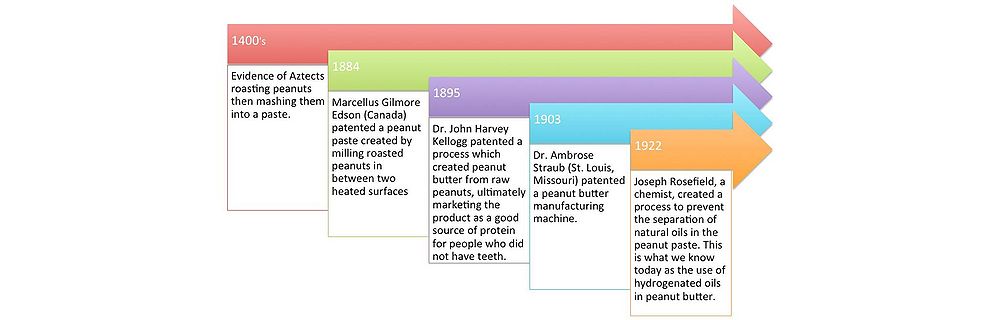

History of Peanut Butter

Ingredients

Two types of peanut butter exist: stabilized or non-stabilized.[1] Stabilized peanut butter refers to the process where additional ingredients and/or additives are added to prevent oil separation that occurs naturally over time.[1] Non-stabilized peanut butter does not undergo any additional processing steps or contain additional ingredients and/or additives that prevent oil separation.[1]

Peanut butter is then categorized into “regular pack style” or “specialty-pack style”. Regular pack peanut butter refers to a stabilized peanut butter prepared using blanched (skinless) peanuts and some amount of additional food ingredient(s). Specialty-pack peanut butter refers to any other peanut butter that does not fall under the definition of regular pack peanut butter.[1] For example, the peanut butter may be non-stabilized, or is prepared using unblanched peanuts, or does not contain any additional food ingredients such as salt or sweeteners.[1]

The main ingredients of peanut butter, based on its method of processing, is discussed below:

Blanched or unblanched peanuts: Blanched peanuts have skin removed from the nut and may or may not contain the germ, while unblanched peanuts have intact skin and germ.[2] Peanut butter is then further classified into three distinct textures: smooth, medium or crunchy based on particle size of the processed peanuts. Peanuts are roasted before being incorporated into the product.[1] See details on peanut butter processing in later section.

Different sweeteners may be included, depending on the nature of the peanut butter product:

Granulated sugar (see also table sugar, or white sugar): pure sucrose refined from sugar cane or sugar beet. The granulated sugar is the most common type of refined sugar, and acts as a sweetening agent in pastries, confections, and other processed foods.[3]

Molasses: byproduct of processing refined sugar from sugar cane or sugar beet. Molasses is a “dark-coloured syrup” that acts as a fermentation agent in alcohol production, baking, and yeast production. In context of peanut butter, molasses may be used to enhance colour, sweeten, and to improve product texture.[4]

Honey: Viscous liquid sugars produced by regurgitation by honey bees. Honey mainly consists of fructose and glucose and is used widely as a sweetener in baking and beverages.[5]

Different stabilizers may be included, depending on the nature of the product, such as “Low-Fat” or “Reduced Fat” products. We will compare the use of hydrogenated versus non-hydrogenated oils as stabilizers in peanut butter later. Some common oils used in peanut butter include:

Palm oil: A saturated vegetable oil derived naturally from the oil palm fruit, which can be derived from various regions in the world. Palm oil mainly consists of a saturated 16-carbon chain with a small fraction of monounsaturated oleic acid.[6]

Soybean oil: Derived from soybean (glycine max) and sometimes hydrogenated in processing. Consists of a combination of unsaturated and saturated fatty acids and is widely used in food processing such as frying and baking.[7]

Vegetable oil: A triglyceride derived from plant sources or a combination of plant sources. Vegetable oil most commonly consists: corn oil, olive oil, canola oil, and soybean among others. Vegetable oil is widely used in food processing and cooking.[7]

Mono and diglycerides (E471): Derived from various plant, animal and synthetic sources. Consists of single fatty acid chain or two fatty acid chains bound together through an ester linkage. Mono and diglycerides food additives and act as emulsifying and stabilizing agents (8).[8]

Some peanut butter products may contain traces of preservatives, and/or other food additives which enhances product quality, which may include:

Magnesium oxide: A mineral salt that acts as an anti-caking agent (prevents food particles from adhering to each other) and buffers pH.[9]

Copper sulfate: A mineral salt that acts as an anti-microbial and anti-caking agent. It is sometimes used in infant formulas to fortify copper content.[10]

Other ingredients may act as stabilizers or for any other function listed above:

Corn syrup or corn maltodextrin: Polysasccharide sugars derived from partial hydrolysis of corn starch.[11] Slightly sweet and odorless. Soluble in water and absorbs oil, which renders it an effective stabilizing agent and improves texture.[12]

According to the U.S. Food and Drug Administration, the product must contain at least 90% peanuts in order to be labeled peanut butter.[1] Products that fall below 90% peanut content must be labeled “peanut butter spread”.[1] Note that there is no Standard of Identity for peanut butter in Canada.[13]

Hydrogenated VS Non-hydrogenated Peanut Butter

How many types of peanut butter are there?

There are two types of peanut butters, hydrogenated (stabilized) peanut butter and non-hydrogenated (non-stabilized) peanut butter (which is commonly known as natural peanut butter). Along with the distinction of natural or hydrogenated, peanut butter can also be further classified into three textures:[1]

-

An example of hydrogenated peanut butter. Photo credit: Kristina Richmond

-

An example of natural peanut butter. Photo credit: Kristina Richmond

- Smooth: the peanut butter has a very fine texture, and there are no perceptible particles

- Medium: the peanut butter has a slight grainy texture, including some perceptible particles

- Crunchy: the peanut butter is partially fine and partially grainy, with larger peanut pieces incorporated.

Hydrogenated Peanut Butter

What Does it Mean if Peanut Butter is Hydrogenated?

During manufacturing, approximately 1-2% (of the total weight of the peanut butter) of hydrogenated vegetable oils are added to the peanut butter.[14]

What is the Purpose of Including Hydrogenated Oils in Peanut Butter?

Hydrogenated oils act as an emulsifying agent. This prevents the natural oils in the peanut butter from separating and rising to the top. It also helps extend the shelf life.

-

The use of hydrogenated oil gives the peanut butter a smooth, creamy texture. Photo credit: freestock.ca

-

The texture of natural peanut butter is quite different compared to hydrogenated peanut butter. Photo Credit: Kristina Richmond

What is an emulsifying agent?

According to Lesson 2 of our course, an emulsifying agent is an ingredient that promotes the formation of emulsions, or to prevent separation of two immiscible phases. Emulsifiers have a hydrophilic and lipophilic component to their chemical structure, which means that they absorb into the interface to create a protective barrier, stabilizing the emulsion by reducing the interfacial tension.[15] This reduces the physical contact between droplets, thus allowing the two phases to stay mixed.[15] Thus in peanut butter, hydrogenated oils act as an emulsifying agent by ensuring that the natural oils formed through the process of making the peanut butter stay in a consistent phase with the peanut paste.

What is hydrogenated (vegetable) oil?

Hydrogenated vegetable oil is vegetable oil that has hydrogen added to it, by forming C-C single bonds from C-C double bonds (this is the process of hydrogenation). This makes the oil more ‘solid’ or ‘spreadable’, and extends the shelf life as well.[16]

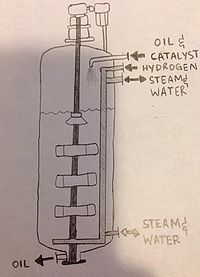

The process of hydrogenation

When food manufacturers want to add hydrogenated oils to their product, they start off with vegetable oils, which contain saturated, monounsaturated and polyunsaturated fatty acids. The bonds that can be easily broken down by oxygen include the mono and polyunsaturated fatty acids, which have double bonds in the “cis” formation. Thus, foods containing unsaturated fatty acids are more prone to oxidation, and are more susceptible to spoilage, producing a rancid taste. To combat spoilage, manufacturers employ a process where hydrogen atoms are added to the available double bonds in the vegetable oil. A greater concentration of hydrogenation yields a greater amount of saturated fats, and a decreasing amount of mono and polyunsaturated fats. As a byproduct, hydrogenation converts “cis” to “trans” double bonds, which produces trans fatty acids.[17] Oils can be fully hydrogenated or partially hydrogenated. fully hydrogenated oils are solid at room temperature and contain 15-25% trans fats, while partially hydrogenated oils are liquid at room temperature and contain less trans fatty acids.[17]

Natural Peanut Butter

Non-hydrogenated peanut butter is also known as ‘natural peanut butter’, which is peanut butter that does not contain any hydrogenated vegetable oils. (Ideally, completely natural peanut butters contain only peanuts and sometimes, salt). Because no emulsifying agents have been added, natural peanut butter will separate into two phases, the peanut oil (top layer) and the peanut paste (bottom layer).

Manufacturing & Processing

As of December 2012, there were 27 establishments classified under Roasted Nut and Peanut Butter Manufacturing in Canada, with 3 of those located in British Columbia.[18]

How Peanut Butter Is Made

First, harvested peanuts are inspected, weighed and graded before they are sent to shelling plants.[19] At the shelling plants the peanuts are cleaned and sorted using both blowing air and gravity tables to separate the peanuts from other unwanted materials.[20] They are then shelled, sorted by size, and sent to the manufacturers.[19] For most types of peanut butter, the peanuts are roasted until they achieve an even brown color. If "raw" peanut butter is desired, this step is skipped.

To stop the cooking process for roasted peanuts, cold air is passed through the nuts. This quickly lowers the temperature to prevent any additional browning.[20] Blanching may be used where the peanuts are sent through brushes or rubber rollers that remove the skins.[20] After blanching, the peanuts go through quality control inspection, and at this time any undesirable nuts are removed.[20]

Finally, the nuts are ground in a mill to become peanut butter. In this process the nuts get heated to 80 degrees Celsius; however, they have to be ground in two stages in order to prevent heating above this temperature, which would cook the peanut butter and yield an unpleasant taste.[19] The type of grinding plate during milling determines the texture of the peanut butter.[20] During the second grinding, salt, sweeteners, or stabilizers can be added to yield the desired final product.[19] After the peanut butter is cooled to 35-50 degrees Celsius, it is packed into jars where it will eventually settle into its final consistency.[20]

Powdered Peanut Butter

A relatively new product called PB2 takes a whole new approach to making peanut butter. During processing, after the peanuts are roasted, they are pressed to remove 85% of their naturally occurring oils.[21] What is left is a powdery substance that the consumer can reconstitute to their preferred consistency. In addition to the peanuts, this product also contains sugar and salt.[21] The main reason proposed for using this product is for the possible health benefits due to the reduced fat and calories compared to traditional peanut butter.[21]

-

PB2 Photo credit: Emilie Thibault

-

PB2 in powdered form. Photo credit: Emilie Thibault

-

After water is added, a peanut butter-like paste is formed. Photo credit: Emilie Thibault

Manufacturing Alternatives to Hydrogenation

Palm Oil

Recently, many manufacturers of peanut butters have been adding palm oil in place of hydrogenated oils, as an emulsifying agent, in order to still be able to market their peanut butters as natural.[22] As mentioned previously, natural peanut butters should ideally contain only ground peanuts and maybe salt. This has been quite a controversial topic for a number of reasons. Firstly, palm oil is extremely high in saturated fat. According to the USDA Agricultural Research Service United States Department of Agriculture, palm oil contains 49.3g of saturated fat per 100g.[23] Another controversial aspect has been the fact that the extraction of palm oil causes a great deal of harm to the environment. Many rainforests and peat lands in Southeast Asia have been destroyed in order to facilitate the planting of palm trees to produce palm oil.[22]

Labeling & Packaging

Labeling

According to Canadian labeling standards, a jar of peanut butter must display the following information:

- Common Name

- Net Weight

- Ingredients

- Durable Life Date

- Nutrition Facts

- Name and Address of the person or company responsible for the food.

According to the Food and Drug Act (FDA), the manufacturer must also state that the product contains peanut and peanut products and where the product was manufactured, in order to reduce risk of potential peanut allergies. Note that peanuts are one of the top ten priority food allergens.[24] To be considered organic, the manufacturer must prove to the FDA that the peanuts used have never been treated with chemicals or pesticides.[25]

Packaging

Peanut butter is commonly packaged in either clear glass or plastic jars. Manufacturers use vacuum sealing methods to remove air from the jars, which helps to prevent oxidation.[26] The foil liners placed on the tops of the jars during this process maintain the airtight seal, and help prevent spoilage over the long term. [27] Peanut butter can also be packaged in small, single serving size containers. You can often find this convenient type of package in restaurants or gas stations. Sometimes peanut butter is also packaged alongside crackers or bread sticks in special snack packs. Unopened, hydrogenated peanut butter is safe to consume for around 1 year past its best before date, while natural peanut butter is only safe for about 2 – 3 months.[28]

Health

Health Concerns – Hydrogenated vs Non-Hydrogenated

Trans Fat in Hydrogenated Peanut Butter

You might have noticed a declaration of 0g trans fat on the label of a jar of peanut butter. This does not mean that the product is completely trans fat free. For a company to be able to make this claim, the product must contain less than 0.4g of trans fat per serving[7]. [29] This small amount of trans fats in peanut butter is not high enough to cause any health damage, if eaten in moderation.

Health Concerns of Trans Fat

Consuming high amounts of trans fat can increase the LDL (bad) cholesterol levels, and lower the HDL (good) cholesterol levels in a person’s system.[30] It has also been known to increase the risk of heart disease and stroke, along with a higher risk of developing type 2 diabetes.[30]

Saturated Fat in Peanut Butter

Peanut butter contains more saturated fat than trans fat. A typical, hydrogenated jar of peanut butter contains 3.3g of saturated fat per serving.[31] This is about 20% of the fat in the peanut butter, which is not an extremely high amount. [31] Similar to trans fats, if eaten in moderation, no significant health damage should occur.

Health Concerns of Saturated Fat

Foods that are high in saturated fats can increase the amount of LDL cholesterol in a person’s blood more than trans fats.[17] Increased levels of cholesterol can increase the risk of heart disease and stroke.[32] Saturated fat promotes artery-clogging atherosclerosis, which is the process that leads to most cardiovascular diseases.[31]

How Can You Avoid the Negative Side Effects of Trans Fat and Saturated Fat?

If you are a consumer who is health conscious about your daily intake of trans fats, it is wise to avoid peanut butters that use hydrogenated oils. The best thing to do is to consume peanut butter that is completely natural. This means that the only ingredient(s) on the label should be “peanuts” (and “salt”). No hydrogenated oils or palm oils has been added to the peanut butter, although you will have to stir the peanut butter to combine the natural oils and the paste before using.

Safety Concerns

Microorganisms

Peanut butter does not pose a great concern in terms of food-borne illnesses. During the production of peanut butter, the peanuts are roasted and reach a water activity of less than 0.7530. The low water activity retards the growth of most microorganisms. The high heat during roasting also kills the microorganisms currently found on the peanuts. There are, however, two prominent microorganisms that can grow when the peanuts are not handled and processed properly.

Salmonella In 2006, a large outbreak of Salmonella tennessee occurred, resulting in 628 infections, 20% of which required hospitalized treatment. After investigation, the outbreak was found to be the result of water moisture dripping from a leaky roof of a Georgia processing plant. The moisture from the roof increased the water activity within the peanuts, allowing the bacterium to thrive and grow. Infections from Salmonella usually result in diarrhea.[33] While mild in most cases, high-risk individuals (infants, elderly, immunocompromised) should seek immediate treatment to prevent complications.

Aspergillus The Aspergillus bacterium family produces metabolites known as alfatoxins. Alfatoxins are highly toxic chemicals that can result in illness when ingested in large amounts. Aspergillus can survive readily in low water activity foods such as roasted peanuts so processing should ensure their complete eradication. Ingestion of alfatoxins over time can result in liver damage and liver cancer.[33][34]

Allergies

Peanut butter is one of Health Canada’s ten priority food allergens and affect 3-4% of the human population within North America. A true food allergy is any food ingredient that elicits an IgE immune response within the body. This results in antibodies attacking particular antigens or proteins found within foods and can result in mild reactions, such as rashes, to more severe reactions, such as anaphylactic shock and death. If a peanut allergy is present, all food products containing peanuts should be avoided. All products containing peanuts must contain peanuts within the ingredient list or indicate “contains” immediately following the ingredients list. Furthermore, all food products with the potential of cross contamination with peanuts must indicate with a “may contain” or “may contain traces of” phrase on the label.[35]

Video

Reflection

After thoroughly exploring the scientific principles and manufacturing processes behind peanut butter, our team has gained some valuable insight into this delicious treat! We have learned a lot about the functions of hydrogenated oils in peanut butter, notably to prevent the separation of oils in natural peanut butter and extend the shelf life of the product. After exploring some of the safety concerns associated with improper handling and manufacturing of the peanut butter, we have learned more about some of the microorganisms that can grow in the product. Finally, we hope that our video, which explores the different types of peanut butters available to consumers, such as hydrogenated peanut butter, reduced fat hydrogenated peanut butter and no-stir 'natural' peanut butter, will help consumers make more conscious decisions when purchasing peanut butter.

Potential Exam Question

What happens during the process of hydrogenation?

A. C-C double bonds are converted into triple bonds.

B. C-C double bonds are converted into single bonds.

C. C-C single bonds are converted into double bonds.

D. C-C single bonds are converted into triple bonds.

E. C-C triple bonds are converted into single bonds.

The answer is b.

References

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 United States Department of Agriculture. "United States Standards for Grades of Peanut Butter." http://www.ams.usda.gov. 5 Feb. 1972. Web.

- ↑ "Unblanched and blanched peanut: Peanut Butter Boy." Peanut Butter 101 [Web log message]. n.d. Web. 28 Mar. 2014.

- ↑ "Types of Sugar." Sugar: Canadian Sugar Institute. Web. 28 Mar. 2014.

- ↑ "What is Molasses?" Molasses: Baking Bites. bakingbites.com. 28 Dec. 2010. Web.

- ↑ "Honey: Honey". Wikipedia, The Free Encyclopedia. Web. 25 Mar. 2014.

- ↑ "Palm oil: Palm oil". Wikipedia, The Free Encyclopedia. Web. 25 Mar. 2014.

- ↑ 7.0 7.1 "Vegetable oil: Vegetable oil". Wikipedia, The Free Encyclopedia. Web. 25 Mar. 2014.

- ↑ "Mono and diglycerides: Diglyceride." Wikipedia, The Free Encyclopedia. Web. 25 Mar. 2014.

- ↑ "Just for Students: Basic Facts About Magnesium Oxide and Magnesium Hydroxide." Magnesia Specialties. 2010. Web.

- ↑ "Copper Sulfate." Nutrifood. INR Food. 2014. Web.

- ↑ "Maltodextrin." Molecular Gastronomy Network. 2014. Web.

- ↑ "Corn Syrup." Center for Science in the Public Interest. https://www.cspinet.org. 2014. Web.

- ↑ "Peanut Bureau of Canada." Think Peanut Butter is Mostly Peanut? Think Again. American Peanut Council of Canada. 12 Oct. 2011. Web.

- ↑ "Peanut Butter Is Trans Fat Free." FoodNavigator.com. N.p., n.d. Web. 29 Mar. 2014.

- ↑ 15.0 15.1 "The Pharmaceutics and Compounding Laboratory." The Pharmaceutics and Compounding Laboratory. UNC School of Pharmacy, n.d. Web. 27 Mar. 2014.

- ↑ "Trans Fatty Acids And Hydrogenated Vegetable Oils." Home. N.p., n.d. Web. 29 Mar. 2014.

- ↑ 17.0 17.1 17.2 Brown, J. Lynne. "Functional Ingredients: Hydrogenated Vegetable Oils and Trans Fatty Acids." Http://www.cas.psu.edu. N.p., n.d. Web.

- ↑ "Canadian Industry Statistics." Establishments: Roasted Nut and Peanut Butter Manufacturing. Industry Canada. Web. 24 Mar. 2014.

- ↑ 19.0 19.1 19.2 19.3 "Peanut Butter Lovers." How it’s made. peanutbutterlovers.com, n.d. Web. 22 Mar. 2014.

- ↑ 20.0 20.1 20.2 20.3 20.4 20.5 "The Peanut Files." How peanut butter is made. Scientific Teaching, n.d. Web. 22 Mar. 2014.

- ↑ 21.0 21.1 21.2 "GNC." PB2 Powdered Peanut Butter. www.gnc.com. Web. 30 Mar. 2014.

- ↑ 22.0 22.1 Aiken, Kristen. "Taste Test: The Best Natural Peanut Butter." The Huffington Post. TheHuffingtonPost.com, 24 Feb. 2012. Web. 29 Mar. 2014.

- ↑ "Show Foods." Show Foods. USDA Agricultural Research Service United States Department of Agriculture, n.d. Web. 29 Mar. 2014.

- ↑ "Common Menu Bar Links." Peanuts: One of the Ten Priority Food Allergens [Health Canada, 2012]. N.p., 03 Dec. 2012. Web. 30 Mar. 2014.

- ↑ Farrelly, Lauren. "FDA Regulations for Peanut Butter." EHow. Demand Media, 31 Aug. 2010. Web. 30 Mar. 2014.

- ↑ ”Packaging.” How Products Are Made: Peanut Butter. Made How. Web. 1 Apr. 2014

- ↑ ”Food Containers.” Plastic Peanut Butter Jars. SKS. Web. 1 Apr. 2014

- ↑ ”How Long Does Peanut Butter Last?” Shelf Life Of Peanut Butter. EATBYDAY. Web. 1 Apr. 2014

- ↑ Elaine Magee, MPH, RDWebMD Expert Column. "Nutty About Peanut Butter." WebMD. WebMD, n.d. Web. 29 Mar. 2014.

- ↑ 30.0 30.1 "Trans Fats." Trans Fats. American Heart Association, n.d. Web. 29 Mar. 2014.

- ↑ 31.0 31.1 31.2 "New Releases." Why Is Peanut Butter "Healthy" If It Has Saturated Fat? Harvard Health, n.d. Web. 29 Mar. 2014.

- ↑ "Saturated Fats." Saturated Fats. American Heart Association, n.d. Web. 27 Mar. 2014.

- ↑ 33.0 33.1 Chang, Alexandra, Aswathy Sreedharan, and Keith Schneider. "Peanut and peanut products: A food safety perspective." ScienceDirect. N.p., n.d. Web. 30 Mar. 2014.

- ↑ Lawley, Richard. "AFLATOXINS." Food Safety Watch. N.p., n.d. Web. 30 Mar. 2014.

- ↑ "Health Canada." Peanuts: One of the ten priority food allergens [Health Canada, 2012]. N.p., 3 Dec. 2012. Web. 30 Mar. 2014.

|

|