Course:FNH200/2013w Team03 Cheese

Introduction

History of cheese

How old is cheese?

The exact time of when cheese first originated is not exactly known, however there is evidence of the practice of cheese making 8000 to 10,000 years ago. [1] One source approximates the origin of cheese around 6500 to 6000 BC in the Fertile Crescent now known as the Middle East. [2] Cheese-making practices are closely related to the history of the domestication of milk producing animals like sheep. Cheese has also been mentioned in ancient greek mythology and evidence of cheese making has been found on Egyptian tomb murals dating back over 4000 years. [1]

It has been briefly mentioned that cheese was discovered from the practice of storing milk in containers made from stomachs of animals. [1] The enzyme rennin in stomach linings, caused milk to separate into different forms like curds and whey. Another explanation to explain the discovery of cheese would come from the practice of putting salt on curdled milk for preservative purposes. While cheese was flourishing in Europe and the Middle East, the art of cheese making was apparently unknown and did not become significant until it was introduced by Europeans.[1]

Cheese production started to spread when Europeans began their expansion globally. Cheese production later arrived in Asia, but never established as a dietary staple and currently is not a heavily consumed food in the regular Asian diet. [1] Even though not all cheese was being accepted as a food staple in the Asian diet, a type of cheese called “rushan” has been produced in China since the beginning of the Ming Dynasty. Until today, that particular type of cheese remains in the diets of the Sani and Bai people of China. [1] Furthermore, the Mongolians and Tibetans have a long history of cheese production that may have initiated cheese-making in china after the previous influence of Europeans and Americans.

Cheese in America

The production of cheese started in the early 17th century when English dairy farmers brought their dairy farming knowledge to New England colonies. Since then, cheese production in America was a farmstead industry. It was mostly women who would make cheese. [1] Furthermore, before the industrialization of the cheese industry, the milk that has been produced on the farm had a shorter expiration date as it would turn sour as preservation methods were limited. Butter was made by using cream, which naturally floats on top of milk, leaving the rest of the milk to make cheese.[1]

Cultural Significance

The importance and significance of cheese shortly after its origin is evident as it is referred to in Biblical accounts in Genesis. [2] Since its origins it has now spread across the globe, but is still primarily consumed by European cultures and more specifically Western European countries. [3] For instance, France is one of the largest producers of cheese producing over 365 varieties totalling over a million tonnes annually, which has resulted in cheese being a “national-specialty” of the country. [4] Cheese is consumed by many cultures throughout the world; however, cheese consumption is not equal across cultures where developed countries generally consume far more cheese per capita than developing countries. [5]

Total world consumption of cheese was 2.86 kg/capita in 2007. [5] In 2007, developed countries consumed 12.44 kg of cheese/capita compared to only 0.64 kg of cheese/capita in developing countries. [5] After developed countries, cheese consumption is highest in the Near East and North Africa (3.42 kg/capita) and Latin America (1.92 kg/capita). [5] However, cheese consumption over the past couple decades has been rapidly growing in developing countries due to continued industrialization resulting in higher incomes and greater demand for dairy products. [5] For instance, in China and the rest of East and Southeast Asia cheese consumption has increased by 3.8% (0.11 to 0.24 kg/capita) from 1987-2007 whereas cheese consumption in developed countries only grew by 1.1% over the same period. [5] Consumption of cheese has also grown substantialy in South Asia including India where from 1987-2007 per capita consumption increased by 4.3%. [5] With regards to particular countries the top ten largest consumers of cheese include:

- France (26.2 kg/capita)

- Iceland (25.2 kg/capita)

- Luxembourg (24.4 kg/capita)

- Germany (24.3 kg/capita)

- Finland (23.7 kg/capita)

- Greece (23.4 kg/capita)

- Switzerland (21.1 kg/capita)

- Italy (20.9 kg/capita)

- Estonia (20.8 kg/capita) and;

- Sweden (19.7 kg/capita). [3]

Canada’s consumption in 2012 was 12.1 kg/capita and the United States’ consumption was 15.2 kg/capita. [3] Some of the smallest consumers of cheese include China (0.1 kg/capita), Mongolia (0.3 kg/capita), Columbia (0.9 kg/capita), South Africa (1.5 kg/capita), and South Korea (2.0 kg/capita). [3] Hence, it can be seen that wealthier countries tend to consume more cheese than poorer nations, but that cultural differences/preferences for cheese are also a factor as well. This is evident by countries such as South Korea, which is a developed country with a standard of living comparable to Canada but whose cheese consumption is significantly less. Other factors associated with varied cheese consumption across cultures includes higher dairy intolerances found amongst people in hot, temperate regions of the world. [6]

Common Types of Cheese

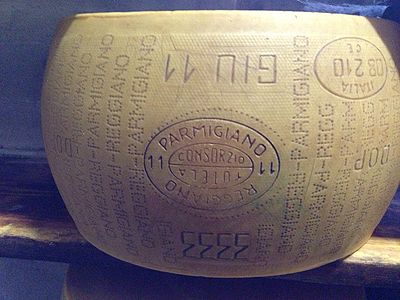

There are approximately 18 distinct varieties of cheese that are each unique in how they are produced based on texture, method of coagulation, and ripening process. [7] Although, within those 18 distinct types it has been estimated that there are over 1500 subvarieties produced across the globe. [7] The 18 types of cheese include: Brick, Camembert, Cheddar, Cottage, Cream, Edam, Guoda, Hand, Limburger, Neufchatel, Parmesan, Provolone, Romano, Roquefort, Sapsago, Swiss, Trappist, and whey cheeses. [7]

Nutritional Composition of Cheese

Cheese is a very nutritious food that is dense in essential nutrients compared to its caloric level. [7] Energy content for a 100 g portion of cheese can range from 98 cal (cottage cheese) to 452 calories (Parmesan). [7] Cheese contains high amounts of bioavailable protein and fats, with protein content ranging from 4-40% (3.1 g for cream cheese to 39.4 g for parmesan per 100 g portion) and fat content also varying substantially (3.9 g for cottage cheese to 47.4 g for cream cheese per 100 g portion) depending on the type. [7] Cheese also has high levels of cholesterol ranging from 10-100mg/100g dependent on the fat content present. [7] Compared to the high fat and protein content found in cheese, carbohydrates are at minimal levels as most of the lactose, which is the primary carbohydrate in milk, are degraded and lost during the cheese making process. [7] Cheese is also a good source of vitamins and minerals including vitamin A, B12, riboflavin, and folate, and the minerals calcium, phosphorus, and magnesium. [7]

Main Ingredients in Cheese

Ingredients For Making Cheese at Home

According to cheese-making experts, cottage cheese is the recommended type to start at home. As we know, cottage cheese is extensively used in Italian cuisine. The ingredients for making cottage cheese include the following: [8]

- 1 gallon of 2% milk

- Half a cup of vinegar

- 1 teaspoon of salt

Note: Cheese can be made silkier by adding fresh cream to it after the pasteurized milk has curdled and you have sprinkled salt on it.

Ingredients For Making Cheese Industrially

Various types of cheese are manufactured commercially, which generally requires more ingredients and equipment for the process. The four main ingredients used in the commercial making of cheese are: [8]

Milk

- Milk is the primary ingredient in making cheese usually supplied from cows, goats and dairy sheep.

Starter

- Starter cultures are used for the production of fermented dairy products, meats, wines, beer and other alcoholic beverages. It is added to the raw ingredients that are to be fermented and grows quickly under the proper conditions provided by the food processor.

Rennet

- Is actually a curdling agent that reacts with milk protein, which causes the milk to separate into solid curd and liquid whey.

Salt

- Salt is added after the rennet to enrich the flavor of the cheese and act as preservation agent. Also, salt helps to drain and firm the cheese. Before the cheese is put into the molds, salt is sprinkled on the curdled milk.

Note: Wax is usually used to bandage the cheese.

Labeling Requirements and Government Regulation

In Canada, the Canadian Food Inspection Agency (CFIA) regulates the labeling of food products. This government agency also works with the Public Health Agency of Canada and Health Canada in close cooperation with health authorities to protect the public from food-borne illness outbreaks. The labeling requirements for processed cheese products are set out in the Food and Drugs Act and Regulations and are enforced by CFIA. Manufacturers must meet the basic requirements, which are described by the Food and Drugs Act and Regulations. The list of the basic requirements include: [9]

- General name of the food

- Net quantity of the food

- Name and address of the manufacturer

- Ingredients of the food (list from largest proportion to smallest proportion)

- The Nutrition Facts Table

- Durable life date and the storage instruction

- Bilingual labeling

Additional Labeling Requirements for Cheese

Fat and Moisture Declaration

Retailers are responsible for ensuring that cheese which they package from bulk on the retail premises are labeled in accordance with the requirements of the Food and Drugs Act and Regulations. [10] The Food and Drugs Regulations (Section B.08.032) requires that cheese labels present on the principal display panel declare the actual percentage of milk fat and moisture content in the product. In the declaration, the words "milk fat" or the abbreviation "B.F." or "M.F." would have to be utilized in conjunction with the percentage of milk fat declared and the word "moisture" or "water" would have to be used in conjunction with the percentage of moisture declared (e.g. "31% M.F. and 39% Moisture"). [10]

Cheese Processing and the Affects of Processing on Properties

Steps in processing and Affect on Cheese Properties

There are 3 stages to converting milk into cheese: coagulation, draining, and ripening. Within each stage there are several processing steps that play a role on the properties of cheese. For example salts, acidity level (pH), amount and type of starter culture, and enzyme activity (proteolytic) all influence flavor and texture of cheese. The compositional and textural differences of milk make for visibly different types of curds. Flavor, aroma, and texture are all predetermined through the manufacturing process and during the ripening stage biochemical changes occur leading to a variety of different cheeses. [11]

Stage 1: Coagulation

Step 1: Pasteurization

Pasteurization is heating food at high temperatures for short periods of time. The raw milk, high in microbial agents and chemicals, is heated at a temperature of at least 72°C for 15 seconds to reduce the amount of microorganisms in the food. [12] Pasteurization of milk causes whey proteins and casein to react, which results in greater retention of whey proteins later affecting ripening and the ability for casein to access the proteinases enzyme. “It takes ten pounds of milk to make one pound of cheese.” [13]

Step 2: Fermentation

Fermentation is used to convert lactose to lactic acid bacteria with the addition starter cultures. Examples of starter cultures are, Streptococcus and Lactobacillus. [13] Formation of curds is done by the addition of rennet, which is found in the fourth stomach of the calf. Rennet’s main function is to separate milk into solid curds, entrapping most of the protein and milk fat, and liquid whey through. The formation of curds is done by rennet acting on the k-casein and hydrolyzing it to form casein micelles. Initially calcium stable, micelles become calcium sensitive and in the presence of lactic acid leads to coagulation aided by temperatures greater than 20°C. The liquid whey retains lactose, minerals, and vitamins. For soft cheese less rennet is used and for harder cheese more rennet is used. The rate of lactic acid production affects the composition, texture, and flavor by directly influencing proteolysis and other reactions. The amount of lactic acid produced directly impacts the activity and retention of the coagulant. The production of lactic acid changes the pH leading to chemical changes in protein of cheese curds. As pH in the cheese curds decreases there is a loss of colloidal calcium phosphate from the casein micelles leading to changes in the solubility of the colloidal calcium ultimately affecting texture, elasticity, and melting rate. [11]

Stage 2: Draining

Step 1: Shaping the Cheese

To speed up the expulsion of whey, curds are cut into smller pieces to allow for syneresis, which is the draining of liquid from gel, as the smaller the curd the faster the rate of syneresis. [11] Not only does the size of the curd affect extraction but also milk composition, particularly calcium level, casein concentration, and pH of the whey. To develop texture, control moisture, and separate the remaining whey from curds even further the cut curds are cooked. After cooking the curds are left to rest where they become knitted affecting texture and allow for lactic acid accumulation. After resting the cheese is cut into smaller pieces, molded, and pressed. During these steps the cheese may lose moisture. [11]

Step 2: Salting

There are 2 types of salting: salt it spread on the cheese or immersed in a salt solution. Method selection varies with type of cheese. Addition of salt impacts many properties of cheese including: [11]

- Decrease speed of ripening;

- Flavour;

- Reduce water activity;

- Starter and non starter lactic acid bacteria and other enzymes;

- Suppress growth of undesirable non-starter microorganisms;

- Metabolism of lactose and pH levels, which affects maturation and quality of cheese; and

- Modifies cheese proteins, which affects texture and protein solubility.

In processed cheese, as salt concentration increases there will be an increase in firmness, pH level, and casein dissociation. Casein, made up of calcium and phosphate groups which are water soluble, is the emulsifying protein within cheese and influences solubility, the more calcium the less soluble the protein. The amount of casein that is coherent affects resistance to flow, hardness, and allows for a higher stress threshold within cheese. [11]

Stage 3: Ripening

Step 1: Moulding

After the cheese has been salted it is put into moulds and shaped either by its own weight due to matting in high moisture cheeses, or mechanically. When subject to pressure the curds form a coherent mass. The cheese is then left in a room where the temperature can be controlled between 35°C to 50°C and moisture can be controlled between 80% to 95%. The cheese is left for changes in chemical and physical properties to occur. [11]

Step 2: Pressing

In low moisture cheese, pressing is used for the expulsion of the remaining whey. Pressing leads to more firm cheese that can be shaped easily. Muslin cloth that has been soaked in warm salted water is used to line the cheese to remove any whey that’s remaining. After approximately 18 hours, the cheese is then removed from the moulds and sealed and wrapped in plastic covering. [11]

Microorganisms Involved With Making Cheese

Aside from the usual ingredients of milk and salt, a crucial part of the cheese-making process is the microorganisms that catalyze the process. These microbes play specific roles to help create the unique characteristics of each type of cheese. In other words, cheese would not exist without these helpful bacteria. A common type of bacteria includes lactic acids, which are considered to be “starter cultures.” [14] Generally, these types of bacteria make lactic acid by converting lactose from the milk (Lahne 2010). The names of these bacteria include lactococci and lactobacilli. [14] The bacteria die out after, but they create flavoring in cheese. Propionic acid bacteria such as Propionobacter shermanii mainly convert acetic acid into propionic acid and carbon dioxide. [14] This specific type of bacteria makes the “holes” that appear in Swiss cheese. [14] Other bacteria that are involved with making blue cheese are called P. roqueforti and P. glaucum, where they grow in small cracks to give a unique flavour. [14] P. camembertii or P. candidum is the white molds that is responsible for creating various types of cheese by using a particular enzyme that breaks down milk proteins to form cheese with curds. [14] The infamous smear bacteria (also known as Brevibacter linens) helps to create red “smear” surfaces on “washed-rind” cheeses. This type of bacteria cannot live in acidic or deoxygenated environments, but instead thrives in salty and moist areas. This results in the bacteria now being able to reproduce within the cheese. After the bacteria break down some of the protein inside the cheese, it creates an “oniony or garlicky, fishy and sweaty aroma.” [14] Cheese's amazing characteristics (including taste and smell) would not be possible without the help of these profound microorganisms.

Illness Caused by Cheese

Listeria

Although cheese is nutritious and delicious, it can also be quite harmful at the same time. A common bacterium that causes a certain illness is Listeria, where the symptoms include: fever, stiff neck, confusion, weakness, vomiting, and diarrhea. [15] The type of cheese that this bacterium is found is soft cheese that is made with unpasteurized milk, where some examples include queso fresco, Feta, Brie or Camembert. [15] Symptoms of this illness appear anywhere form 3 to 70 days after consumption and can last from several days to weeks. [15] Patients who have a higher risk of contracting this disease are usually pregnant women, seniors, or someone who is immune-deficient. [15] The disease can be avoided by staying away from raw or unpasteurized milk or cheese that is made from unpasteurized milk. [15]

Brucellosis

Brucellosis is another disease that can be caused by cheese, where it can cause nausea, vomiting, headaches, diarrhea, etc. This disease supposedly originated from cows, pigs, goats or dogs, but it can be transmitted over to humans through direct contact or consuming their raw milk. [16] This method of transfer seems to be the major route of transmutation. [16] Cheese should be comsued often for its nutritional value; however, it would never hurt to be sure whether or not the milk used to make the cheese has been pasteurized or not.

References:

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 National Historic Cheese Making Center. (2010). Brief History of Cheese. Retrieved from: http://www.nationalhistoriccheesemakingcenter.org/Cheesemaking-History.aspx

- ↑ 2.0 2.1 Kindstedt, P. S. (2012). Cheese and Culture - A History of Cheese and its Place in Western Civilization. White River Junction, VT: Chelsea Green Publishing

- ↑ 3.0 3.1 3.2 3.3 Canadian Dairy Informaton Center. (2013). Global Consumption of Dairy Products. Retrieved from: http://www.dairyinfo.gc.ca/pdf/consumption_global_cheese_e.pdf .

- ↑ Toussaint-Samat, M. (2009). A History of Food. Malden, MA: Blackwell Publishing Ltd.

- ↑ 5.0 5.1 5.2 5.3 5.4 5.5 5.6 Gerosa, S & Skoet, J. (2012). Milk availability - Trends in production and demand and medium-term outlook. Retrieved from: http://www.fao.org/docrep/015/an450e/an450e00.pdf

- ↑ Rebora, G. (2001). Culture of the Fork:A Brief History of Food in Europe. United States: Columbia University Press.

- ↑ 7.0 7.1 7.2 7.3 7.4 7.5 7.6 7.7 7.8 Fox, P. F., McSweeney, P. L. H., Cogan, T. M., & Guinee, T. P. (Eds.) (2004). Cheese: Chemistry, Physics, and Microbiology (3rd ed.). San Diego, CA: Elsevier Academic Press

- ↑ 8.0 8.1 Satalkar, B. (2011). Cheese Ingredients. Buzzle.com. Retrieved from: http://www.buzzle.com/articles/cheese-ingredients.html

- ↑ Canadian Food Inspection Agency. (2013). Basic Labeling Requirements. Last accessed 23 March 2014 at: http://www.inspection.gc.ca/food/labelling/food-labelling-for-industry/eng/1383607266489/1383607344939

- ↑ 10.0 10.1 Canadian Food Inspection Agency. (2012). Cheese - Fat and Moisture Declaration. Last accessed 23 March 2014 at: http://www.inspection.gc.ca/food/retail-food/information-bulletins/cheese/eng/1331659072899/1331659154169

- ↑ 11.0 11.1 11.2 11.3 11.4 11.5 11.6 11.7 Murtaza, M., Ur-Rehman, S., Anjum, F., Huma, N., & Hafiz, I. (2014). Cheddar Cheese Ripening and Flavor Characterization: A Review. Critical Reviews In Food Science & Nutrition, 54(10)

- ↑ Todar, K. (2009). The Control of Microbial Growth. Retrieved from http://textbookofbacteriology.net/themicrobialworld/control.html

- ↑ 13.0 13.1 University of Wisconsin. (2011). The Art of Cheesemaking. Retrieved from https://www.youtube.com/watch?v=7-s2Kql0CHI

- ↑ 14.0 14.1 14.2 14.3 14.4 14.5 14.6 Lahne, J. (2010). Serious Cheese: Know Your Microbes. SeriousEats. Retrieved from: http://www.seriouseats.com/2010/02/what-microbes-make-cheese.html

- ↑ 15.0 15.1 15.2 15.3 15.4 Foodsafety. (2009). Listeria. Retrieved from: http://www.foodsafety.gov/poisoning/causes/bacteriaviruses/listeria/

- ↑ 16.0 16.1 World Health Organization. (2010). Brucellosis. Retrieved from: http://www.who.int/zoonoses/diseases/brucellosis/en/

Video:

Exam Question:

Why is rennet an important part of the fermentation of cheese?

a. initiates the formation of curds, separating it from whey

b. makes cheddar cheese yellow

c. allows for a rapid syneresis (draining) of cheese

d. decreases the water activity in cheese

|

|