Course:FNH200/2013w Team01 Alcohol

Beer is an alcoholic beverage that is produced by brewing yeast-fermented malt with hops to impart a bitter flavour. Beer is the third most widely consumed beverage in the world behind water and tea. Beer has been ranked as the most consumed alcoholic beverage. The alcohol content of beer is usually between 4% to 6% by volume, although it can vary between 0.5% in de-alcoholized beer, all the way up to 20% in speciality brewed beers. It is considered by some historians to be one of the oldest fermented beverages.

History

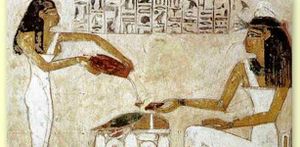

Beer is one of history's oldest prepared beverages, which has been recorded in ancient Egypt and ancient Iraq dating back to 9500 BC. It is also the first known product that humans made from grain and water, even before making bread. THe earliest forms of beer were cloudy and unfiltered and often had to be drank with a straw to avoid consuming bitter chunks of solids from the brew. In 1516, the "Bavarian Purity Law" established that beer could only be brewed from the ingredients water, hops, and malts. Yeast was later discovered as the organism responsible for fermentation. Nearly every culture has developed their own kind of beer using different kinds of grains. For example, the Chinese used wheat, while the Japanese used rice, and the Egyptians used barley. The modern day methods of brewing beer did not begin until the invention of automatic bottling, commercial refrigeration, and pasteurization.

Standarization

The food regulations of the food and drugs act standardize beer as "the product of the alcoholic fermentation by yeast of an infusion of barley or wheat malt and hops or hop extract in potable water and shall be brewed in such a manner as to possess the aroma, taste and character commonly attributed to beer."

More info on regulations for beer in canada can be found on government Canada's agriculture and Agri-Food website.

Hops

Hops are a species of female flowering plants found in Homulus lupulus. Hops came to be used many thousand years after people started brewing beer. Most brewed beers nowadays consist of hops, as it gives a preferable bitterness and most of all contributes to a longer shelf life and preservation. Before the use of hops in brewing beer, it was used in many ways. The shoots were used in salads, the flowers were stuffed in pillows to help insomniacs, their resins were used in shampoos and as a hide tanning preservative.

The first documented evidence between hops and brewing was in 822 AD when Abbot Adalhard of the Benedictine Monastery wrote a series of statutes regarding the running of the monastery which included gathering hops for making beer. Recorded evidence suggests that commercial hop cultivation began in northern Germany between the 12th and 13th century. The Germans exported hopped beer from the 13th century onwards. The first evidence of hopped beer being brewed in England was in 1412, which produced both un-hopped “ale” and hopped “beer.” On April 23, 1516 the Bavarian Reinheitsgebot declared hops as one of the three allowable beer ingredients (before yeast was discovered). In 1710, the English parliament banned the use of non-hop bittering agents, and eventually hops became the dominant bittering agent in beer throughout the Western world.

In beer, hops provide bitterness to balance the flavours, aromas, as well as the sweetness of malt sugars. Hops also provide resins that increase head retention, as well as antiseptics to prevent spoilage. Often referred to as a “vine”, hops are actually a “bine”, which are plants that use a strong stem and stiff hairs to climb, rather than use tendrils and suckers to attach. The plant has separate male and female bines, but only the female bines develop cones. If male plants are allowed to pollinate them, the flowers will produce seeds, rendering them useless for brewing. It is the flower of the hop plant that is used in brewing. Hop flowers or cones resemble pine cones but are composed of thin, green, papery leaf-like bracts. At the base of these bracts are waxy, yellow lupulin glands that contain alpha acids responsible for the bitterness and essential oils that give beer its flavour and aroma. During the boiling step of beer production, alpha acids are isomerized and increase international bittering units (IBUs).

International Bittering Units (IBU)

The International Bitterness Units scale, or IBU scale, provides a measure of the bitterness of beer, which is provided by the hops used during brewing. An IBU is one part per million of isohumulone — the higher the number, the greater the bitterness.

Continental (Noble Hops): 7.8, Cascade: 7, Northern Brewer: 7.8

Hop Production

The majority of the worlds commercial hops are produced between latitudes 35°~55°, either north or south of the equator. Today the largest producers of hops for brewing beer are Germany, the US, China, Czech Republic, England, and New Zealand. Hop plants sprout in the spring and die back to a cold-hardy rhizome in the fall. During peak growing season they grow very rapidly (up to 20 inches per week). Commercial hop growers cultivate hop bines on V-shaped, wire and twine trellises that are up to 20 feet tall. In spring, at the start of the growing season, two to three young shoots are trained in a clockwise direction around each horizontal length of twine. The harvest season begins in August and continues into October. Harvesting machines cut the bines and twine at the top and bottom and load them onto trucks. Then they are passed through a series of sorters to separate the cones from the stems and leaves. The cones are placed in a kiln where 140° air is circulated, drying the cones to about 30% of their green weight. After cooling, the cones are compressed into bales or further processed into pellets or extracts.

Hops Preservative Qualities

The alpha and beta acids in hops are both vulnerable to oxidation which will decrease their effectiveness. Hops will degrade faster at temperatures above freezing. Hops should be stored in a freezer, and sealed in an airtight container (that is ideally a vacuum packed foil oxygen barrier container) to prevent oxidation.

Hops Variety

Continental (Noble Hops)

The noble hops originate in central Europe and are among the most prized of the aroma hops. There are four noble hops, Hallertau, Tettnang, Spalt, and Czech Saaz. These hops impart a smooth bitterness and spicy/floral aromas. The noble hops are often used in lagers. Common descriptors for these hops include spicy, black pepper, licorice, perfume, floral, and herbal.

Cascade

These hops are most commonly used at craft breweries in the US. A visual characteristic of the plant is its dark green elongated cones which contain moderate to somewhat high amounts of alpha acids compared to many other hop types. The resultant aroma is very distinct. It has a pleasant, flowery and spicy, citrus-like quality. The hop is good for both flavour and aroma uses. It can also be used for bittering effectively, and can be used to make ales, as well as some lagers.

Northern Brewer

These hops were developed in England in 1934 by crossing a Canterbury Golding female plant and the male plant OB21. It is grown in Europe and America as a dual-purpose hop, but mainly used for bittering in combination with other hops. It gives a woody, earthy, and fruity aroma and flavour.

Hops Usage in Brewing

Boil Hops: Hops added during the main boil period to add bitterness and flavour to beer.

Aroma Hops: Hops added at the end of the boil to add aroma.

Dry Hops: Hops added during the secondary fermentation, usually a day or two prior to bottling for added extra aroma.

Mash Hops: Hops added to the mash tun, to effectively get steeped and add flavour (contribute less towards bitterness at this step)

First Wort Hops: Hops added to the boiler as the wort is first being sparged. These hops effectively get steeped and then boiled with the main boil. First wort hopping results in a better blending of hops flavour with the wort, however it generally reduces hop utilization slightly when compared to traditional boiled hops.

Brewing Grains

Brewing grains are the solid residue that remains after the germinating and drying cereal grains (malt) which are used in the production of beer. The most typically used brewing grain in beer production is malted barley or barley malt. Although a variety of other grains, malted or unmalted, can be used which includes wheat, corn, rice, rye, and oats. Brewing grains provide the characteristic colour, aroma, flavour profile, and body of the beer. The grains provide simple sugars for the yeast to ferment into alcohol The grains supply essential minerals which are necessary for yeast growth The proteins from the grains are what give structure to beer foam, as well as a produce a silky mouthfeel. Grains also produce complex sugars which can impart an aftertaste of sweetness and can add flavours ranging from toffee, to cocoa, or coffee.

Malt

Malt is cereal grain that has undergone the controlled germination and kilning of grain. Before grain can be converted into alcohol, the complex carbohydrates must be broken down into simple sugars, which is carried out by malting. The malting process develops diastatic enzymes that convert starch to sugar during brewing which enables the starches to be more accessible to the brewer. Barley is the most commonly malted grain, but other grains such as wheat and rye can also be malted. Types of Malt Base Malts Base malts make up the majority of fermentable ingredients in beer recipes, ranging from 60 to 100%. They have a high enzyme concentration which helps convert the starch to sugar. Low temperature and short duration kilning makes base malts the lightest coloured of the brewing malts. Standard malted barley base malts go by the names Pale, Munich, Marris Otter or Pilsner.

Malt Extract

Malt extract is base malt that has been mashed and condensed. Extract can be liquid or powdered, and ranges in colours from light, to amber or dark. The low temperature kilning of base malts allows them to retain the highest level of potential sugar and the highest diastatic power of all the malt types. Having a high diastatic power means that they contribute a large amount of sugar to the beer and are able to convert not only their own starches but also other grain sugars with lower diastatic power. For this reason, base malts make up the bulk of the grain bill for any brewing recipe, usually at least 85%.

Caramel/Crystal Malts

To create caramel malts, green malt is moved to a roaster after germination rather than being dried. Inside the roaster the grains are heated between 150°F to 158°F, which is the temperature that activates certain diastatic enzymes. These enzymes convert the starches into sugars inside the grain, leaving them in a semi-liquid state. After being converted, the grains are roasted at temperatures between 220°F and 320°F according to the colour and flavour desired. Roasting at a higher temperature causes caramelization of the sugars into less fermentable forms and darkening of the grain through the Maillard reaction. Lighter caramel malts impart honey and caramel flavors, while the darker caramel malts give off toffee, burnt sugar, and raisin-like flavours.

Unmalted Grains

In addition to malted grains, brewers also use a variety of unmalted grains known as adjuncts. These include rice, corn, barley, wheat, rye, and flaked oats. Adjuncts serve a variety of purposes such as lightening body and colour, increasing body, adding complexity to flavour and aroma, and making gluten free beers. These unmalted grains are pressed under hot rollers, which preserves the proteins that help with head retention and provide a smooth mouthfeel.

Roasted grains

Roasted grains provide dark brown to black color and a coffee, cocoa, burnt and bitter flavours to the beer. They are cooked at higher temperatures than caramel malts and for a longer period of time. The intensity of the roast is measured in Lovibond, ranging from 350L for a chocolate malt to 500L for a black malt. Roasted grains give stouts and porters their characteristic dark colour and rich flavour.

Yeast

Yeasts can be classified into the fungi kingdom and can be defined as having a nucleus (eukaryotic) and account for about 1% of all fungal species. Yeasts can be found anywhere around us whether in the soil like mushrooms, on plants as well as in the air (spores). Yeasts are generally unicellular but multicellular species do exist and the size of these organisms can vary anywhere from 3-4 micrometers in diameter to 40 micrometers in diameter. Most of these species of fungi reproduce asexually by mitosis which is a process also used in somatic cells where a singular cell replicates their DNA and undergoes four phases (prophase, metaphase, anaphase, telophase) until it splits into two identical daughter cells. However, some species are more prone to use budding which is when part of the membrane “buds” out and eventually is separated from the parent organism. This new bud grows into another yeast cell eventually. The main form of yeast metabolism is through fermentation which is a process where the yeast cell (other species can also use fermentation) breaks down glucose (C6H12O6) into acids, gasses and/or alcohol. Fermentation is the organism’s way to make energy from glucose into ATP (Adenosine triphosphate) which is a molecule with high energy phosphate bonds that stores the energy as chemical energy. In commercial food industry as well as in the everyday consumers, we take advantage of the fact that yeasts use fermentation in order to make foods like cheeses, beers, wines, breads and many more.

Types of Yeast

| Yeast Type | Usage |

|---|---|

| Active Dry Yeast | This type of yeast requires dissolving in warm liquid before using and should never be heated past 110F. This yeast is usually sold in small jars. |

| Baker’s Yeast | This type of yeast contains all forms of Saccharomyces cerevisiae and is available in liquid, fresh, active dry and instant forms. Generally, Baker’s Yeast is used for the making of various bread products. |

| Brewer's Yeast | Used in beer and contributes to flavour |

| Bread Machine Yeast | Same as instant yeast and is used in bread machines but does not require re-hydration or dissolving |

| Fresh Yeast | Sold in compressed or cake form and is extremely perishable (should be used within a couple weeks of purchase) Must also be dissolved before adding to recipe. |

| Instant Yeast | Most active form of yeast commercially available. Does not require hydration and has a long shelf life. |

| Liquid Yeast | Most popular form prior to the invention of cake or compressed yeast. This type consists of a mixture of live yeast organisms, flour and water. |

| Nutritional Yeast | Deactivated form or yeast and is used as a supplement as it is a good source of minerals and vitamin B |

| Rapid Rise Yeast | Same type of yeast as bread machine or instant yeast and will stay active up to 130F |

| Yeast Extract | Concentrated nutritional yeast in the form of a paste |

Yeasts in Beer

In the beer industry, yeast cultures are used to produce the alcohol in beer as well as some of its distinct taste. Beer makers take advantage of the fact that yeasts use fermentation as its way to convert glucose or other fermentable sugars into alcohol and its by-products. These by-products can impact the flavour as well as the aroma and the most noticeable products of yeast are ethanol and carbon dioxide. Other flavour by-products that are produced may include but not limited to:

| Chemical | Aroma/Flavour |

|---|---|

| Acetaldehyde | Green Apple |

| Diacetyl | Butter/Butterscotch |

| Dimethyl Sulfide | Cooked Veggies |

| Esters | Fruit Aromas |

| Sulfur | Rotten Eggs |

There are generally two types of yeast involved in beer making which include top-fermenting yeast and bottom-fermenting yeast.

Top-Fermenting Yeast

Generally used to brew ales, they are best used at temperatures ranging from 10 to 25C. However, some strains of top-fermenting yeast will not be active below 12C. These yeasts generally rise to the surface of the liquid during fermentation which creates a thick yeast layer. Top-fermenting yeasts are used for brewing ales, porters, stouts, Altbier, Kolsch and wheat beers.

Bottom-Fermenting Yeast

Generally used to brew lagers and is best used at temperatures of 7 to 15C and they grow slower than ale yeasts. Near the end of the fermentation process, these types of yeast sink to the bottom which gives rise to the name of bottom yeasts. The flavour of the final product is dependent on the temperature of the fermentation as well as the strain of yeast.

Wyeast Yeast Products

This is the product that is used during the brewing process of the beer in our FNH project beer. The yeast blend that is sold by this company is packaged in a liquid slurry and in an optimum condition for storage. The product also includes an activator pouch that when smacked, will release its contents into the yeast and thus activating it. Instructions from the manufacturer that are included with a package of their yeast product are:

1. To Activate, locate and move inner packet to a corner. Place this area in palm of one hand and firmly smack the package with the other hand to break the inner nutrient packet. Confirm the inner packet is broken.

2. Shake the package well to release the nutrients.

3. Allow the package to incubate and swell for 3 hours or more (it is not necessary for this package to fully swell before use) at 70-75°F (21-24°C).

4. Use sanitizing solution to sanitize the package before opening.

5. Shake well, open and pour the Activator™ into 5 gallons of well aerated or oxygenated wort up to 1.060 OG at 65-72°F (18-22°C). Maintain temperature until fermentation is evident by CO2 bubble formation, bubbling airlock or foaming on top of wort. For high gravity or low temperature fermentations additional yeast may be required.

6. Adjust to desired fermentation temperature.

Packaging

There are varieties of ways in which beer can be packaged; they are typically packed in containers such as cans, glass bottles, and even barrels and tank containers. Most of the time, beer is cleared of yeast by filtering during the packaging process. The most critical part about packaging beer would be to prevent it from being contaminated by excess yeasts, and to keep oxygen out from the beer. Such things like excess yeast and typically have a negative impact on the shelf life of beer. During the process of beer bottling, empty bottles are first lined up on the bottling line, where they are rinsed with chlorine solution and later sprayed with CO2 to remove this solution. These bottles are then moved to a turret-like device where it is again sprayed with large amounts of CO2 prior being filed with beer, this process is necessary in order to prevent too much foaming during filling. Next, the filled bottles are transported to the capping machine where it must first go through a high-pressure jet of water that removes air out of the bottle. The cap is then put onto the bottle before any air can go into the bottle, and lastly a label is sealed onto the bottle surface.

Labelling Can and bottle beer labels must follow the guidelines set by the Consumer Packaging and Labelling Act and Regulations. However there are a few differences. Standardized alcoholic beverages such as wine and beer are exempt from adding the ingredients list. The nutrition table is also exempt on standardized alcoholic beverages unless the beverage has a nutritive claim. Alcoholic products must show the alcohol by volume percentage as well.

Other Ingredients Commonly Used

Irish Moss Irish moss is used in beer making as a fining agent. Protein molecules in the beer are small and seperated, allowing them to remain suspended in the liquid. Irish moss clumps the proteins together, forming larger molecules. These molecules fall to the bottom of the beer and are left at the bottom of the carboy during racking. This creates a clearer beer.

Gypsum

Gypsum is used to change the water chemistry of the water you start with during the wort making process. Some particular styles of beer require a certain acidity or hardness of the water. By addng gypsum you can increase the waters acidity. Gypsum can also increase the bitter taste or crispness of the beer.

Team1 India Pale Ale Recipe

Beer Recipe Slideshow File:Beer slide show-1 2.pptx

For our project we have decided to explore the steps of brewing an India Pale Ale. Let's first start with the ingredients:

Amber Malt Dry Extract 500 grams,

Golden Malt Dry Extract 500 grams,

Pilsner Light Malt Dry Extract 500 grams,

Cascade Hops 2 oz / 57 grams,

Northern Brewer Hops 1 oz / 28 grams,

Centennial Hops 1 oz / 28 grams,

Irish Moss 1 tsp,

Gypsum 2 tsp,

Wyeast* California Lager Liquid Yeast I bag,

Corn Sugar ¾ cups

Equipment

5 Gallon Pot,

Plastic Tubing,

Primary Fermenter – 25 Gallon Plastic Bucket,

Secondary Fermenter - 23 Liter Glass Carboy,

Rubber stopper and Air Lock System,

Big Spoon,

Thermometer,

Specific Gravity Gauge – optional,

Chlorinated Tri Sodium Phosphate – sanitizing agent

Attention - All equipment used must be sanitized before use. Sanitation in the most important rule to prevent the beer from spoiling.

Activate the yeast package 2-3 hours before you intend to use it.

Brewing the Wort – Brew time 1 hour Fill a 5 gallon stock pot with 3 gallons of water. Set the pot on a stove set on high and bring to a boil. Right away before the water boils add the 2 tsp of gypsum. Once the water is boiling, add all 1500 grams of the malt extracts. Remember to stir the dry extract constantly while adding it so that it does not fall to the bottom of the pot and burn. Add 1 oz of the cascade hops, and 0.5 oz of the centennial hops as soon as you are finished adding the malt extract. Boil for 30 minutes. Stir occasionally. After 30 minutes, add 0.5 oz of both the norther brewer and cascade hops. Also add 1 tsp of irish moss. Boil for 25 minutes. With 5 minutes left, add the rest of the hops, 0.5 oz of all three hop varieties. Allow to boil for the remainding 5 minutes and then take the pot off the stove to cool down.

Fill the primary fermenter with 2 gallons of cold water. Slowly add the 3 gallons of brewed wort to the 2 gallons of cold water in the primary fermenter. The goal here is to cool it down as quickly as possible. If you can put the primary fermenter in a ice bath this will speed the process up.

Pitching the Yeast When the wort has cooled down to anywhere between 65 to 72 degrees farrenhiet we can add the yeast. Before adding the yeast you can check the beers specific gravity. Add the yeast to the wort and lightly mix with a spoon. Cover the primary fermenter with a lid and store at room temperature (65-72 f).

Ferment for 7 days in Primary Fermenter

Racking After 7 days, the wort is ready to be racked. Racking basically means transferring the wort from one fermenter to another without unsettling the solid material at the bottom of the primary fermenter. This creates a clearer beer. Set the primary fermenter on a raised surface, and using a plastic tube, siphon the wort into the secondary fermenter (glass carboy) on the ground. Make sure to use an air lock to plug the carboy, this allows gas to escape the carboy, but does not allow oxygen in.

Ferment for another 1 to 2 weeks

Priming Have your bottles all ready for use. Sanitized and cleaned.

Dissolve ¾ cup of corn sugar into the primary fermenter using about 2 cups of warm water. Siphon the wort back into the primary fermenter the same way it was done during the racking stage. Mix the wort with a spoon to evenly disperse the sugar.

Now siphon the wort into the beer bottles. This can be made easier with the use of a pressurized stopper. This device allows flow when it is being pushed in, (say at the bottom of a beer bottle), but stops flow when the pressure is released. Fill the beer bottles and cap them with a bottle capper.

Wait 2 weeks before drinking. This will ensure that all the corn sugar was created into carbon dioxide, creating carbonation.

Enjoy!

Final Exam Question

What principal of preservation is used during the production of beer?

i) Microbial Antagonism

ii) Thermal Processing

iii)Antimicrobial Agents

iv) Freezing

a) i and ii only

b) i and iii only

c) i and iv only

d) iii and iv only

e) ii and iii only

f) none of the above

g) all of the above

The answer to this question is (b)

Reflection

After going through different aspects of beer and its production, some of its concepts may extend beyond the brewing industry. As many of us already know, fermentation is a way of converting sugars into other substances like alcohol in beer as well as other compounds. As a result, fermentation is a process where it can be used as a form of preservation which impacts other industries beyond beer and wine making. For example, in the pickling process where cucumbers are turned to pickles, fermentation is used to preserve the cucumber in the form of pickles with the use of salty brine. Other industries may also incorporate fermentation in their preservation process while making some foods may be a different way of prolonging shelf life of some foods.

Moreover, yeasts play a significant role in the flavour of beer in addition to the alcohol they produce through fermentation. We realized that different strains of yeast whether bottom or top fermenting can result in a variety of flavours which may influence the industry because new strains may be found to produce other new flavours of beer. This allows for the beer industry to continue innovating beer brewing that exists today into more efficient ways to make flavourful beer. Although beer making may not resonate with everyone as many people are not into alcohol, the process of how beer is made has a fundamental impact on consumer living as fermentation of products is a major part of society. A major theme we have come across during our research is that even though the theme of our project may not be applicable to everyone in society, the fundamental concepts of our project may resonate more with consumer living.

We've also learned the significance hops plants came to be in regards to brewing beer. Its applications of preservation in giving more longevity to the beer products as well as its distinct bitter/fruity aroma flavor appeals a lot to consumers as not many better/less costly alternatives presents itself for a good beer. Given what we have learned, it is safe to say that hops is one of today's most important ingredients for brewing beer.

During the beer making process, we realized how important sterilization and cleanliness is. It is very important to keep things clean, because if one piece of equipment has any foreign microorganisms on it, the whole batch could be ruined. We also realized how easy it is to make beer at home. The process does not take a long time, nor does it ask for a lot of expensive ingredients. And the beer can turn out better than some of the commercial beers on the market today.

References

http://www.aperfectpint.net/Brewing%20Grains.pdf

http://www.feedipedia.org/node/74

http://drinks.seriouseats.com/2011/01/homebrewing-basics-all-about-grain-what-is-malt-extract.html

https://www.wyeastlab.com/hb_products.cfm

https://www.wyeastlab.com/hb_productdetail.cfm?ProductID=16

http://www.beeradvocate.com/beer/101/yeast/

http://foodreference.about.com/od/Ingredients_Basics/a/Yeast-Varieties.htm

Bellis, Mary. "The History of Beer." Beer was the first alcoholic beverage known to civilization. About.com Inventors, n.d. Web. 30 Mar 2014. <http://inventors.about.com/od/bstartinventions/a/beer.htm>.

http://www.inspection.gc.ca/english/fssa/labeti/guide/ch2e.shtml

http://zythophile.wordpress.com/2009/11/20/a-short-history-of-hops/

http://laws.justice.gc.ca/eng/regulations/C.R.C.,_c._870/

|

|