Course:FNH200/2012w Team14 PeanutButter

Introduction

Uploaded to Flickr by Certified Su

Peanut butter is a paste made from ground roasted peanuts, often used as a spread or with cooking.[1] It has become one of North America’s staples and can be found in three-fourths of the pantries across the country.[2] In order to use the term “Peanut Butter” the product (both commercial and natural) must contain a minimum of 90% peanuts and have no artificial sweeteners, colors, or preservatives.[2]What started as a simple vegetarian protein has turned into a sandwich favorite with about 700 million pounds being consumed each year.[2] More than half (50%) of the peanuts that are grown are used in the manufacturing of peanut butter[2]. With that being said, peanut butter today is remarkably similar to that produced a century ago,[3] and still remains a versatile and flavorful ingredient.

History of Peanut Butter

Uploaded to Flickr by Roadsidepictures

As peanuts have been used throughout the world for various purposes since at least the 15th century, the exact origin is not entirely known. [4] However, the original maker of peanut butter is believed to have been from St. Louis, Missouri. In 1890, an unknown doctor developed peanut butter as a protein substitute for patients unable to chew meat[4]. While he may have discovered the nutritious paste, credit for peanut butter products is given to Dr. John Harvey Kellogg of Battle Creek, Michigan, who worked with his brother to develop a patent for the product in 1895.[5] Unlike manufacturing processes today that use roasting, the Kelloggs brothers steamed their peanuts, which is a comparatively less desirable method.

With the help of several others, peanut butter was refined and officially introduced at the Universal Exposition of 1904 in St. Louis.[4][5] While its popularity was growing, in 1922, chemist Joseph Rosefield saw the need to prevent the separation of the product, and added hydrogenated vegetable oil into the mix.[5] The creamy and thick resulting product was the start of the Skippy brand which was established and distributing peanut butter by 1933.[4] Competing with other companies, including Peter Pan and Heinz, peanut butter became a food favourite. Despite the nut-allergy fears of the 1990s, peanut butter remains a successful $800 million industry.[5]

Peanut Butter Manufacturing Processes

Natural Peanut Butter Manufacturing

Although there is no standard identity for Peanut Butter in Canada, [6] products advertised as Natural Peanut Butter tend to have no hydrogenated oils, high fructose corn syrup, or trans fats added to them. [7] Companies such as Smucker's,[8] Adam's, [7] and Kraft.[9] have only roasted peanuts and a miniscule amount of salt in their peanut butter. These types of natural peanut butters require stirring after being opened because the oil separates and pools on the top of the paste while a hard, inedible substance forms at the bottom. [6] Because of these drawbacks with purely natural peanut butter, some companies such as Skippy,[10] produce natural peanut butter that does not need to be stirred, and instead have added palm oil to stabilize nuts in the oil. This variety of natural peanut butter also include salt, sugar, or molasses added to them. Natural peanut butter sales are increased because of a growing demand for all-natural products. [11] For example, in 2011 natural peanut butter sales increased by 9.4% in the United States. [12]

Commercial Production

The initial steps of manufacturing both natural and hydrogenated peanut butter are very similar. There are three types of peanuts that can be used to make peanut butter, Virginia, Spanish, and Runner-type peanuts. [13] Runner-type peanuts are the best peanuts used for making peanut butter because they are a uniform size, which allows them to roast evenly. [14] Peanuts are harvested, shelled, and graded, then arrive at the peanut butter manufacturing plant. [13]

Process of Commercial Production of Natural Peanut Butter

- The first process they undergo is roasting. At a high temperature, peanuts are dry roasted to give them a more intense flavor. [13] Peanuts are roasted in a revolving or shaking oven at very high temperatures for 40-60 minutes to ensure each nut is roasted evenly to the exact degree, and A photometer will indicate when they are done roasting. [13]

- Peanuts are then quickly removed from heat and moved into a perforated metal cylinder [13] where suction fans circulate the air quickly. [14] It is important that cooling is rapid so the peanuts do not lose too much oil. [13] They then remain at room temperature and foreign materials are removed via a gravity separator. [13]

- The peanuts then go through the blanching process in which the skins and heart are removed. [14] The outer skin is removed by heat blanching, by exposing the peanuts to high temperatures for a short period of time to loosen and crack the skins. [13] They are then passed through the blancher and brushes or rubber belts gently remove the skins. [13] The kernels are then split in two and the blancher removes the bitter heart of the peanut. [14]

- The peanuts are then ground twice, first to a medium grind and then to a fine smooth texture [13]. In the case of chunky peanut butter, small chunks of peanut are mixed with the finely ground peanut butter, or incomplete grinding is used by removing a rib from the grinder.[13] For the variations of natural peanut butter, a small amount palm oil, salt, or sweetening agents are added before the initial grinding.

- From the grinder, the peanut butter goes into a hopper to mix and store. The peanut butter is then cooled in a votator to room temperature. [13]

- Peanut butter is finally packaged in jars, capped, and labeled. Vacuum packaging is often used to reduce oxidation.[13]

Additives and Stabilizers

Despite being labelled as 'natural' or 'all-natural,' many peanut butters, especially natural non-stir ones contain ingredients besides peanuts.

Salt

Adding salt is common in all types of natural peanut butters, even those that require stirring. Salts added typically consist of sodium chloride and potassium chloride. [11] The salt content of these peanut butters are generally quite low, typically less than about 4% of the product.[11] Not only is salt added for flavoring and textural purposes, but it also helps to control the moisture content. Low water activity is crucial, as it helps to keep the natural stabilizer effective and extend shelf life. [11]

Sugar/Sweeteners

Natural sweetening agents are sometimes added to the non-stir variations of natural peanut butter to achieve a flavor similar to hydrogenated peanut butter. [15] Common sweeteners include sucrose, dextrose, molasses, and honey.[11] The sweeteners usually consist of less than about 10% weight of the peanut butter, most preferably 1-4%.[11] Sweeteners are added to enhance the flavor, texture, and mouth feel of peanut butter and also control water activity like salt does.

Oil

For natural peanut butter products, a natural stabilizer will be added and mixed with the peanut butter paste to create a homogeneous mixture of the stabilizer, peanut particles and peanut oil which do not separate.[11] Fatty acids from non-animal products, such as peanut and palm oil, are the far most common in Canada and the USA, although it is possible for cream, butter, animal fats, or a combination of these to be used.[11] The fatty acid forms a matrix with the two ingredients, stopping separation and creates a firm texture.[11] These natural fatty acids range from milk products from livestock, to many different types of plant oil, animal fats, or a combination of both.[11] It is important to note that none of these stabilizers are modified fatty acids that have been chemically altered by processes such as hydrogenation.[11]

Production of Homemade Peanut Butter

Our group made natural no-stir peanut butter, following the steps of a recipe we found online [16]

- We first obtained 2 cups of shelled peanuts and roasted them at 350° for about 8 minutes in the oven. We shook them frequently as they burn easily!

- After they cooled, we put them in a food processor.

- We added 1 tbsp. vegetable oil (to prevent separation), a 1 tbsp of honey (for flavor), and a pinch of salt (for flavor).

- The chopping process took about two minutes. The mixture clumped at first, so we had to manually stir it in order to achieve a smooth consistency.

- We then put our peanut butter into an airtight container. The product separated at first, but with a bit of stirring and time in the refrigerator, it set into a smooth consistency and great flavor!

Partially Hydrogenated Manufacturing

Uploaded to Freestock by Nicholas Raymond

This process of peanut butter production was first invented to prevent oil separation during storage of the product overtime.[17] Normally, peanut butter is made from raw peanut kernals that have been roasted, blanched, then grinded, with the addition of liquid oil, sweetners, and salt, along with emulsifiers to reduce stickiness. [17]. While the nut particles are suspended in the oil, the product forms a spreadable paste[18] Overtime, this suspension will separate forming an oil layer on top, and a crumbly hard layer underneath [18]. Incorporation of partially hydrogenated or fully hydrogenated oils or fats can prevent this separation to a certain degree, thus serving as stabilizers in peanut butter. [18]

Commercial Production

The major steps in commercially produced peanut butter [19]

- Cleaning and shelling of whole peanuts.

- In order to split the peanuts, remove the skins then the embryo, the shelled peanuts are put under both heat and mechanical processing. The skins must be removed so the distinctive red color is not mixed into the final product. The embryos undergo a process known as blanching, as they are removed due to lipids found within them which would form bitter compounds after deterioration that would ultimately affect the flavor of peanut butter.

- Blanched peanuts are then oven roasted either in oil or dry to destroy any enzymes found in the peanuts that could cause undesired oil breakdown and produce off-flavors in the peanut butter. Roasting also creates changes in the peanut’s color, flavor and texture for a desired outcome. The browning reaction created in color is from sugars reacting with amino acids, which adds to the pleasant peanut flavor by several chemical compounds, as well as altering the carbohydrate and protein structures of the peanut to produce more tenderness.

- Next, the oil (hydrogenated vegetable oil or peanut oil), carbohydrate, emulsifier, and salt are all added into the finely grounded peanut mixture. Different companies then choose the ingredients and conditions of processing that meets their standards of the product. Common emulsifiers include monoglycerides and diglycerides that meet the functionality and safety regulations of the government. They usually take up less than 0.5% of the product’s weight. Sugar and salt make up the pleasant flavor of the peanut butter. The composition of the final product must be a minimum of 90% peanuts and a maximum of 55% fat (~50% from peanuts, the rest from oil) to fit the closely regulated FDA standards. No preservatives, colors, flavors, or vitamins are then added.

- A smooth mass is produced as the final mixture undergoes a mechanical blend that forms an emulsion by finely dispersing the oils to prevent separation upon transportation and storage.

- Finally, the finished peanut butter is put into jars which are then sealed and labeled.

Additives and Stabilizers

As mentioned above, partially hydrogenated fats and oils are added to the mixture of blended peanut butter to serve as a stabilizer which prevents separation of oils and also creates the desirable consistency without further stirring. [18], [20] These additives form a crystal matrix which prevent the peanut particles from settling and causes rigidity in the product[18]. However, due to the high melting point of some additives, the peanut butter may result as not spreadable and firm.[18] The purpose of adding in stabilizers to peanut butter is to create a pleasant mouth-melt property and to reduce stickiness.[18] The final outcome of peanut butter is to reduce its stiff and waxy texture as much as possible while still being stable.[18]

A common additive used to stabilize peanut butter is partially hydrogenated palm oil, as it is a triglyceride oil with an Iodine Value (IV) of 25-45.[18]. The IV of an oil or fat is important because it determines the fat solid contents at a particular temperature.[18] The content of solids at certain temperatures of a fat or oil is critical for determining the amount of stability and the texture of the peanut butter.[18] The lower the IV of an additive, the higher the content of solids are at certain temperatures.[18] Partially hydrogenated palm oil (or other similar partially hydrogenated triglycerides such as soybean oil or coconut oil) has a fat solids content of 80-90% at relatively lower temperatures of around 10 degrees Celsius and less than 50% at higher temperatures of around 47 degrees Celsius.[18] When making peanut butter, the amount of partially hydrogenated oil added is in a small range of strictly 1-4%, most desirably 1.5-3.5%.[18]. Less than 1% could lead to possible oil separation, in which the additive would have no benefit to the product, and more than 4% added could cause the peanut butter to be undesirably firm with a waxy taste.[18]

Uploaded to Flickr by Seven Morris

Reduced Calorie Peanut Butter

In the past, it has been shown that in order to create a low calorie peanut butter (which is at least 15% fewer calories than the original), there are several give-and-take factors involved. Yokoyama, Fraser, and Khatri stated in their 1989 US patent that the creation of a low calorie peanut butter without altering the texture or flavor of the original product was unsuccessful. The choice of adding solid bulking agents with lower calories to peanut butter will result in this undesirable change to the product.[21] Most of the calories in peanut butter come from its fat content (about 72% of calories), and if this content were to be reduced to 42%, the texture would be significantly stiffer, and even more reduction would lead to a powder form of peanut butter.[21]

Things have progressed in the 20 years since the attempt to make low calorie peanut butter. There is now a powdered peanut butter called PB2 with 85% less calories per serving compared to normal peanut butter.[22] This product is formed by squeezing out all fat and oil content in the peanuts to result in the all natural, no preservatives, or artificial sweeteners peanut butter powder.[22] In numbers, that is going from 190 calories per 2 tablespoons to 45 calories.[23] This powdered peanut butter can be mixed with water to form the familiar texture of normal peanut butter at a much lower calorie count.[23] It is an alternative to the original higher calorie peanut butter however, the low calorie count also comes with a lower nutritional value as it does not contain the daily value % of such vitamins and minerals found in the original product.[23]

Comparison Summary of both Manufacturing Processes

The major difference between Natural Peanut Butter and Partially Hydrogenated Peanut Butter is the addition of a hydrogenated oil (vegetable, palm, etc.)in the natural peanut butter mixture before it is sealed [18]. This is to help with the consistency, texture and mouth melt of the peanut butter [18]. It creates a smoother texture that does not require stirring after opening nor the separation of oils and the dense bottom part of the peanut butter [17]. It makes peanut butter easier to eat for consumers[20]. The downside is that with the added oil, there follows more health risks for the public.

It is important to consider that non-stir Natural Peanut Butter still have non-hydrogenated stabilizers and other natural flavoring additives in it. This is more convenient for consumers, and emulates the texture and flavor of Partially Hydrogenated Peanut Butter which many consumers prefer. [15] While these natural no-stir peanut butters are seen as natural, and therefore healthier, they still have added oils which could pose potential health risks. [15] These process show that is it challenging to provide "natural" products to a modern market that prefers convenient and flavorful food which can only achieved by adding extra ingredients and stabilizers.

Labeling & Packaging Requirements

Labeling Requirements

According to the Canadian Food Inspection Agency, there is no standard of identity for the food we call “peanut butter”. There is no obligation to list percentage of peanuts either as this information is considered proprietary of the individual production companies. Kraft was happy to disclose that their All Natural Peanut Butter is 100% made of peanuts while their Smooth Peanut Butter has between 75% and 100% peanuts in it. [6] However in the US, the Food Drug Administration requires that 90% or more of the product must include peanuts to be able to be called “peanut butter”. Any products with a percentage of peanuts lower than 90% is labeled “peanut spread” instead. [6] If the product does not fulfill the basic FDA standard of identity, it is called “imitation peanut butter” [13] Apart from the standard labeling regulations, the most important information that must be included on peanut butter whether it is “peanut spread” or “imitation peanut butter” is that the product contains and has come in contact with peanuts. Although this seems obvious, it can be integral in saving lives as peanut allergy is considered a major, top 10 allergen. [24][25]

Packaging Requirements

Standard sizes for peanut butter are 250g, 375g, 500g, 750g, 1kg, 1.5kg and 2kg. [26] Most popular methods of packaging are glass or plastic jars which are then sealed on top after being vacuum packed. This prevents oxidation from happening. [13]

Uploaded to Flickr by CW3283

Shelf Life

Whether peanut butter needs to be refrigerated has been hotly contested by scientists. There is a general conception that most foods can be kept longer if done so. When it comes to peanut butter, being refrigerated causes the oil and the spread to separate or solidify, making it more difficult to spread. In a paper published in the Journal of Food Science, it was discovered that peanut butter with 2.5% palm oil had a longer shelf life in comparison to unstabilized peanut butter. Shelf life of 113 days versus 75 days. [27]

Health Concerns

Peanut Allergies

A food allergy is an adverse immune reaction towards food proteins.[28] Peanut allergies are common especially in children—although it is thought that some children grow out of it (prevalence in children ~1%; in adults 0.26%). [28] [29] Symptoms can range from mild reactions such as rash, hives and itching, to life threatening anaphylactic reactions such as tightening of throat, shortness of breath or wheezing.[29] Even trace amounts are enough for some people to have a severe reaction.[29] As a consequence, any facility that manufactures peanut products or may come into contact with peanut products must be very careful to avoid cross contamination with peanut free product lines.

Processing Considerations

Consumers who have peanut allergies rely on the accuracy of the ingredient information that is provided by food companies.[30] Certain factors that must be considered such as:

- Proper cleaning of food equipment so that potentially allergenic ingredients do not contaminate other product lines.[30]

- Proper packaging and labeling with complete ingredient information.[30]

Uploaded to Flickr by Mags_cat

To ensure the safety of food products and to avoid recalls, the Canadian Food Inspection Agency “strongly encourages” Canadian food companies to obtain allergy information from their manufacturer suppliers.[30]

Hydrogenation Concerns

As discussed in Section 3 Peanut Butter Manufacturing, hydrogenation is a processing step that is done to commercial smooth or chunky versions of peanut butter. The purpose is to produce a homogenous end product of which the peanut oil does not separate out onto the top.[31] “Natural” peanut butters are generally not as smooth in texture and require stirring to mix in the oil layer. During the hydrogenation process, hydrogen reacts with unsaturated carbon-carbon double bonds in the molecule with liquid, unsaturated fatty acids oils. The result is a more stable and solid peanut butter product.[31] The more saturated the oil, the more solid the product. Peanut butter is commonly partially hydrogenated meaning that some of the oil is left in the unsaturated liquid form in order to maintain a spreadable product.[31] Hydrogenation is a common process used to make margarine or shortening from vegetable oils.[31]

Health concerns about hydrogenation involves the undesired production of trans-fats. They are produced during the hydrogenation process when some of the unsaturated fatty acids become only partially saturated changing the formation of the double bonds in the molecule. Trans fats are considered saturated fats (fully hydrogenated, no double bonds) even though they still contain double bonds. The reason for this is that trans fats behave in the body the same way as saturated fats in raising bad cholesterol (LDL) and lowering good cholesterol (HDL).[31]

In peanut butter, only a little over 1% of the total content is partially hydrogenated oil used for stabilization.[31] Of this, trans fats are only a small portion of the 1%; as a result, the amount of trans fats are not detectible. Overall, the stabilization of peanut butter and flavouring of sugar and salt does not change the macronutrient content substantially from “natural” peanut butter and according to the US Department of Agriculture (USDA) “the consumption of peanut butter should not be of concern to individuals monitoring trans-fatty acid intake”.[31]

Toxins

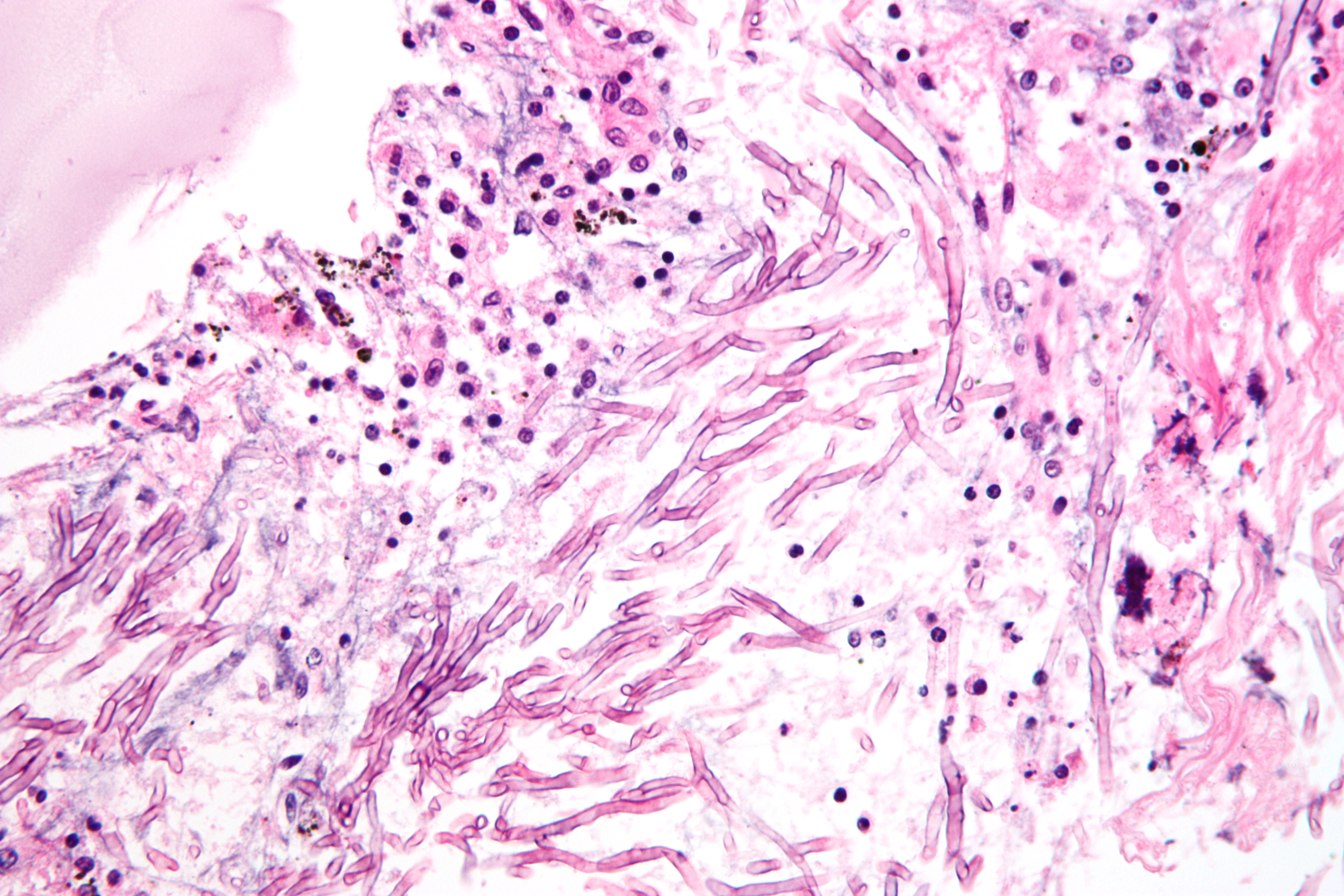

Peanut-containing legume pods are harvested from the earth and are therefore susceptible to molds present in the soil. Of major concern is the mold Aspergillis flavus (A. Flavus). Crops are most vulnerable to infestation with prolonged exposure to high humidity while growing or following harvest.[32]

A. flavus itself is known to cause human and animal infections known as Aspergillosis.[33] Aspergillosis infections can include clinical allergies (e.g. allergic lung reactions), superficial and local infections (skin or fungal ear infections) infections associated with damaged tissue (aspergilloma (clump of fungus in body cavity such as the lung), bone infections), and invasive pulmonary and extrapulmonary infections.[33] Of major concern to peanut butter manufacturers is aflotoxicosis, an illness due to aflatoxin produced by A. flavus. The toxin can become incorporated into processed products such as peanut butter and once ingested, the toxin is a recognized, potent liver carcinogen.[32] [34]

Maximum levels of potentially harmful chemicals are established by Health Canada in order to reduce the risk of resulting adverse effects (enforced by the Canadian Food Inspection Agency).[35] Due to the health concerns associated with A. flavus, Health Canada has established maximum levels allowable in peanut products. Health Canada allows 15 parts per billion (ppb) for aflatoxins in nuts and nut products (B.01.046(n) of the Food and Drug Regulations).[32] Recently as part of the Food and Safety Action Plan to improve Canada’s food safety various foods were tested for hazards.[32] Of particular interest is that of the various types of food tested (figs, dates, corn, nut products) nut butters had the highest levels of aflatoxins detected with some products exceeding the allowable limit.[32] No recalls resulted from the findings however notification of the producer or importer, follow-up inspections, additional sampling, and possible product recalls may result if the violations are not corrected.[32] Companies that manufacture peanut products must be vigilant in ensuring that the raw products they import follow Canadian safety guidelines.

Conclusion

As you can see, peanut butter is a very versatile food. What was once a protein substitute has flourished into the delicious spread we use today. It has become an important ingredient in recipes, and used as a savory addition to sauces. The two common forms of peanut butter, natural and commercial under go various manufacturing steps that are quite similar. However, the main difference between the two is the addition of hydrogenated oil that is added to natural peanut butter. North American society has shifted towards a “natural” way of life, thus increasing sales of natural peanut butter. However, with added oils comes an added heath risk, proving a challenge for peanut butter manufactures. Peanut Butter, as stated above, is made up of 90% peanuts, but most products contain additives such as salt, sugar or sweeteners and oil. These ingredients are added to enhance the overall flavor and texture. With that being said, peanut butter has no standard of identity and peanut butter manufactures have no obligation to list the percentage of peanuts on the label. Nevertheless, the most important requirement that is present on the label of peanut butter is the allergy caution. With increases in peanut butter allergies, more companies, especially those who manufacture peanut products, are becoming more careful with potential cross contamination. With that being said, peanut butter will still remain a staple in the North American diet.

Possible Exam Question

Of the known mycotoxins (sterigmatocystin, ochratoxin A, aflatoxins, citrinin and patulin), which one(s) are the greatest health concern due to their potent liver toxicity that are found in peanut butter manufacturers?

Answer: aflatoxins

References

- ↑ Peanut butter. (2013). Retrieved from http://dictionary.reference.com/browse/peanut+butter

- ↑ 2.0 2.1 2.2 2.3 The Peanut Institute. (2010). Peanut Products. Retrieved from http://www.peanut-institute.org/peanut-products/peanut-butter.asp

- ↑ Food service. (2013). Peanut Butter lovers. Retrieved from http://peanutbutterlovers.com/foodservice/

- ↑ 4.0 4.1 4.2 4.3 Linn, Virginia. (1997, March). The early history of peanut butter. Pittsburg Post-Gazette. Retrieved from http://www.lexisnexis.com/hottopics/lnacademic/?verb=sr&csi=144577&sr=HLEAD%28THE+EARLY+HISTORY+OF+PEANUT+BUTTER%29+and+date+is+March+26%2C+1997

- ↑ 5.0 5.1 5.2 5.3 Suddath, Claire. (2009, February). A brief history of peanut butter. Retrieved from http://www.time.com/time/magazine/article/0,9171,1879180,00.html

- ↑ 6.0 6.1 6.2 6.3 Schwartz, R. (2011). Think peanut butter is mostly peanuts? Think again. Retrieved from http://www.peanutbureau.ca/MainMenu/Media-Resources/News/Think-peanut-butter-is-mostly-peanuts-Think-againl

- ↑ 7.0 7.1 Adam's. (2013). Natural Peanut Butter. Retrieved from http://www.adamspeanutbutter.com/product

- ↑ Smucker’s Products. (2012). Natural Creamy Peanut Butter. Retrieved from http://www.smuckers.com/products/ProductDetail.aspx?groupId=2&categoryId=11&flavorId=65

- ↑ Kraft. (2011.) Kraft Peanut Butter Product Information. Retrieved from http://www.kraftcanada.com/en/products/p-r/kraftpeanutbutter.aspx

- ↑ Skippy. (2012). Skippy ® Natural Creamy. Retrieved from http://www.peanutbutter.com/product/detail/115202/skippy-peanut-butter-natural-creamy

- ↑ 11.00 11.01 11.02 11.03 11.04 11.05 11.06 11.07 11.08 11.09 11.10 Milley, C.J. (2004). U.S. Patent no 6,703,064. Washington, DC: U.S Patent and Trademark Office.

- ↑ Natural Peanut Butter Spreads. (2012). Food Technology, 65(32), 18.

- ↑ 13.00 13.01 13.02 13.03 13.04 13.05 13.06 13.07 13.08 13.09 13.10 13.11 13.12 13.13 13.14 How Products Are Made. (2007). Peanut Butter. Retrieved from http://www.madehow.com/Volume-1/Peanut-Butter.html

- ↑ 14.0 14.1 14.2 14.3 How it's Made. (2007, August 28). How Peanut Butter is Made [Video File]. Retrieved from http://www.youtube.com/watch?v=6H_M6yw32M0

- ↑ 15.0 15.1 15.2 Peanut Butter Boy. (2013). Peanut Butter 101. Retrieved from: http://www.peanutbutterboy.com/peanut-butter-101/

- ↑ How to make natural peanut butter. (n.d.) WikiHow. Retrieved from http://www.wikihow.com/Make-Peanut-Butter.

- ↑ 17.0 17.1 17.2 Widlak, Neil. (2002) US Patent No. : 6,447,833 B1. Decatur, IL: Archer-Daniels-Midland Company

- ↑ 18.00 18.01 18.02 18.03 18.04 18.05 18.06 18.07 18.08 18.09 18.10 18.11 18.12 18.13 18.14 18.15 18.16 McCoy, Stephen A.(1982) US Patent No.: 4,341,814. Cincinnati, Ohio: The Procter and Gamble Company

- ↑ Institute of Food Technologists.(no date found). Acitvity #4: Effect of Roasting on Color, Flavour, and Texture of Peanut Butter. Experiments in Food Science(pp. 2-3).

- ↑ 20.0 20.1 Food Additives. (2008). Learning Seed (pp.4). Chicago, Illinois: Suite 301

- ↑ 21.0 21.1 Yokoyama, Wallace H., Fraser, Mark S., Khatri, Lakho L. (1989). US Patent No.: 4,814,195. Fullerton, California: Winters Canning Co.

- ↑ 22.0 22.1 Torrisi, Lauren. (2012) Low-Cal Peanut Butter Is a Dream for Dieters. Retrieved from http://abcnews.go.com/blogs/lifestyle/2012/07/low-cal-peanut-butter-is-a-dream-for-dieters/

- ↑ 23.0 23.1 23.2 Snack Girl. (2012) Peanut Butter Lovers: A 45 Calorie Solution That Will Save Your Waistline. Retrieved from http://www.snack-girl.com/snack/low-calorie-peanut-butter-pb2/

- ↑ U.S. Food and Drug Administration. (2013). Food Allergen Labeling and Consumer Protection Act of 2004 (Public Law 108-282, Title II). Retrieved from http://www.fda.gov/Food/GuidanceRegulation/GuidanceDocumentsRegulatoryInformation/Allergens/GuidanceComplianceRegulatoryInformation/ucm106187.htm

- ↑ Health Canada. (2012). Peanuts - One of the ten priority food allergens. Retrieved from http://www.hc-sc.gc.ca/fn-an/pubs/securit/2012-allergen_peanut-arachide/index-eng.php

- ↑ Canadian Food Inspection Agency. (2012). Basic Labelling Requirements, Sections 2.10-2.18. Retrieved from http://www.inspection.gc.ca/english/fssa/labeti/guide/ch2ae.shtml

- ↑ Gills, L.A. (2008). Sensory and Physical Properties of Peanut Butter Treated with Palm Oil and Hydrogenated Vegetable Oil to Prevent Oil Separation. Food Science, 65, 173–180. doi:10.1111/j.1365-2621.2000.tb15975.x

- ↑ 28.0 28.1 Health Canada. (2010). Research related to the prevalence of food allergies and intolerances. Retrieved from http://www.hc-sc.gc.ca/fn-an/securit/allerg/res-prog/allergen_research-eng.php

- ↑ 29.0 29.1 29.2 Mayo Clinic. (2012). Peanut Allergy. Retrieved from http://www.mayoclinic.com/health/peanut-allergy/DS00710

- ↑ 30.0 30.1 30.2 30.3 Canadian Food Inspection Agency. (2013). A tool for managing allergen risks in food products. Retrieved from http://www.inspection.gc.ca/food/labelling/core-requirements/ingredients/allergen-labelling/allergen-risks/eng/1357659722449/1357665699917

- ↑ 31.0 31.1 31.2 31.3 31.4 31.5 31.6 What's the spread on peanut butter. (2006). Food for Thought: The Peanut Institute, 10(2). Retrieved from http://www.peanut-institute.org/resources/downloads/fft_v10i2.pdf

- ↑ 32.0 32.1 32.2 32.3 32.4 32.5 Canadian Food Inspection Agency. (2012). 2010-2011 aflatoxins in dried fruits, nuts and nut products, and corn products. Retrieved from http://www.inspection.gc.ca/food/chemical-residues-microbiology/chemical-residues/aflatoxins/eng/1347377061474/1347377332021

- ↑ 33.0 33.1 Cornell University. (2013). Aflatoxins: Occurrence and health risks. Plants Poisonous to Livestock. Retrieved from http://www.ansci.cornell.edu/plants/toxicagents/aflatoxin/aflatoxin.html

- ↑ Public Health Agency of Canada. (2011). Pathogen safety data sheet: Aspergillus spp. Retrieved from http://www.phac-aspc.gc.ca/lab-bio/res/psds-ftss/aspergillus-spp-eng.php

- ↑ Health Canada. (2010). Canadian standards (maximum levels) for various chemical contaminants in foods. Retrieved from http://www.hc-sc.gc.ca/fn-an/securit/chem-chim/contaminants-guidelines-directives-eng.php