Course:FNH200/2012w Team08 SoftCookies

COMMERCIALLY-MADE SOFT-BAKED CHOCOLATE CHIPS COOKIES

Introduction

You’re a five-year-old child and the aroma of fresh, soft-baked cookies fills the kitchen. Your mouth waters in anticipation of eating the tender dough, gently pulling the cookie into smaller pieces to dip into a glass of milk – the perfect after school snack. But as you grow older, free time is scarce, and baking your own cookies becomes a time-consuming chore that isn’t worth the effort when you have higher priority obligations to fulfill. What do you turn to, to relive this nostalgia? You begin to open your kitchen cupboards, searching for something to fill the craving. That’s when it catches your eye: store-bought, commercially made, soft-baked chocolate chip cookies. The search is over; but you wonder, how do they preserve that “soft-baked” quality? You begin to fathom how these cookies seemingly melt in your mouth and have that “just-came-out-of-the-oven" quality to them, even though they’ve been sitting in your pantry for weeks. What’s the difference between mom’s soft-baked cookies and these commercially made counterparts? How do manufacturers keep these deliciously homey treats soft for so long? Why don’t they turn crunchy, crispy and stale once the package has been opened?

History and Present Day

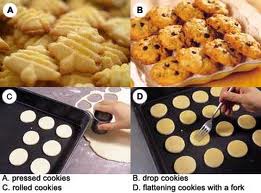

The word cookie is derived from the Dutch term, “Koekje”, meaning “little cake.”[1] Culinary historians from all over the world believe that this food was first conceived when cooks and bakers used small amounts of cake batter to test the temperature of an oven before baking a large cake.[1] However, it is to no surprise that at the time, different “Koekjes” were being created in different counties and cultures. Specifically, chefs in Britain incorporated “biscuits” into their tea service in the 19th century, and Scotland introduced “sweet buns.”[1] In America, a Massachusetts innkeeper named Ruth Wakfield didn’t have enough nuts for her cookie recipe and substituted them with a bar of baking chocolate, creating the infamous “Toll House Cookie.”[1] From this burst of culinary creativity bloomed cookies of all different varieties and for all different occasions. With endless combinations and permutations, the types of cookies in our present day are vast and can be tailored to anyone and everyone’s desires. In this regard, cookies are now classified based on their method of preparation: drop (placing spoonfuls of cookie dough onto a baking tray), molded (hand-formed into balls or logs), pressed (pressing cookie dough through a pastry bag to form different designs and shapes), refrigerated (cookie dough is formed into a log, refrigerated until firm, then sliced and baked), bar (cookie dough fills a shallow tray and is baked, cooled and cut into bars), and rolled (cookie dough is rolled flat, and cookie cutters or pointed knives are used to create different shapes).[2] They can then be further categorized based on the primary ingredient included (e.g. chocolate, fruits, nuts), size (e.g. bite-sized, monster-sized), if it is gourmet, and on the texture (e.g. soft-baked, crispy), which brings us to our topic: soft-baked cookies.[2]

Characteristics

Texture

The texture of soft-baked cookies is based on a manufacturer’s recipe of fats, proteins and starches, carbohydrates and sugars, leavening agents, sodium chloride and water to create the characteristic spongy, chewy and crumbly in their product. By manipulating these ingredients, different soft-baked cookie qualities, densities, and storage lives can be obtained. Specifically, the higher the batter viscosity, the lower the saturated fat content and the lower the air retention during battering, baking and storage, the denser and harder the cookies will be.[3] [4]

Soft baked cookies are easy to shear because a high amount of saturated fat is used. Fat tenderizes the flour, and increase air volume through aeration. Saturated fats like butter and shortening are preferable because they remain soft and in a semi-solid state at room temperature.[3] During baking, the temperature should not exceed the smoking point (temperature at which fat is broken down into it’s constituent fatty acid and glycerol structures) of fat because fat will evaporate and the function of fat will no longer exist.[5]

White wheat cake flour that contains 8-10% of gluten protein or all purpose white wheat flour that contains 9%-12% of gluten protein is most often used in soft-baked cookies. They are most oftenly used because they contain a lower amount of protein than other types of flours and do not contain fiber. Protein level tends to be low because an excess of protein will increase the batter viscosity and increase its hardness.[4] In addition, proteins stiffen when they experience rapid coagulation at high baking temperatures.[6] However, it is important to remember that there still needs to be a small amount of protein present to act as an emulsifier and create a stable structure so the finished product will not collapse. The flour particles should be small enough so the surface ratio of flour will increase, and this should allow more fat to coat on the flour to create an lighter and flakier texture. Except this, the dough will not bond to large air bubbles when the flour particle is small. Instead, it will bond to smaller air bubble. The smaller the bubble size, the stronger the bond between the air and the dough; therefore, increasing its air retention rate. In order to obtain a smaller flour particle, the grain used for milling must be soft. Commercial factories also use bleached flour, which has finer particles than unbleached flour because of the addition of bleaching agents in the process of flour making.[4]

A higher amount of salt (sodium chloride, NaCl) in the cookie batter (3% or more relative to the amount of gluten protein in the flour) will decrease the water retention in starch and protein during starch gelatinization and protein coagulation at baking. Therefore, the higher the salt concentration present, both the cookie’s shearing capacity and elasticity will decrease. However, a minimal addition of salt (~ 2% relative to the gluten protein in flour) will enhance the protein network (bonding between proteins) to allow the protein to capture more air. Therefore, a higher amount of air can be retained in the dough.[7]

Leavening agents like baking soda, ammonium bicarbonate and Cream of Tartar (potassium tartrate) are added to the dough to increase the air volume. Baking soda can react with acid or be thermally decomposed at 70 degrees Celsius to produce CO2 and increase the air volume. Ammonium bicarbonate also shares this quality, but it decomposed in a lower temperature (36 degrees Celsius). Cream of Tartar is acidic in nature and it is used to react with baking soda to produce CO2. Below are the chemical equations to illustrate these processes.[8]

Thermal decomposition of baking soda at 70 degrees Celsius:[8]

- 2NaHCO3 → Na2CO3 + H2O + CO2(g)

Thermal decomposition of ammonium bicarbonate at 36 degrees Celsius:[8]

- NH4HCO3 → NH3 + H2O + CO2(g)

The acid and base reaction of baking soda and Cream of Tatar: [8]

- KC4H5O6 + NaHCO3 → NaKC4H4O6 + H2O + CO2(g)

Egg is often added to soft-baked cookies. The egg yolk acts as an emulsifier and creates a soft gel, helical structure to capture water.[3] Egg whites are added to provide moisture, as 92% of egg whites are composed of water. During baking, the evaporation of water will help the cookie dough rise as water vaporization creates an upward force.[6]

Flavour (Taste and Aroma) and Visual Enhancement

Flavour varies from product to product depending on a cookie’s ingredient-composition and processing procedure.

In soft-baked cookies, different oil and fat ingredients contain different sets of aromatic constituents. For example, modified palm oil adds an oily note to soft-bake cookies, but do not contain any aromatic compounds. In contrast, butter contains aromatically-active compounds that provides creamy, cheesy, and buttery notes to soft-baked cookies.[9]

A greater amount of sugar, inverted sugar or sugar substitutes are added to cookies to create a sweet sensation. Intense sweetness is often utilized to mask the salty taste of sodium chloride.[3] Some companies will use molasses or brown sugar as an additional sweetener to provide a brown colour and a distinct flavour from its caramelization.[3] Moreover, the most popular visual enhancements, Caramel Color, is created from caramelizing carbohydrates. Caramel Color can provide an attractive brown color to the cookies but can also profile a bitter flavour and a smell of burning sugar.[10]

Ingredients like cinnamon and vanilla extract may be added to give the cookie extra flavour and aroma. The use of powdered cinnamon tends to yield a weaker fragrant, and a sweeter and warmer flavour than stick cinnamon.[11] Vanilla extract can provide a woody and smoky flavor to soft-baked cookies that may be desirable to consumers.

The Characteristics of the Chocolate Chips in the Soft Baked Cookies

Most companies use semi-sweet chocolate that contains at least 35% solid cocoa (chocolate liquor and at least 18% coca butter), sugar (natural sugar or sugar substitute) and vanilla extract as a flavor enhancer. Lecithin, an amphipathic, commercially-created fatty substance made by mixing phospholipids in oil, is added to the chocolate chunks as an emulsifier and lubricant.[12] Besides emulsification and lubrication, lecithin also helps smoothen the chocolate by decreasing sugar crystallization, helps solidification by reducing the chocolate’s viscosity, increases the chocolate’s ability to withstand high temperature, and prolonging the cookie’s shelf-life. Lecithin is especially important because it helps retain the shape of the chocolate during baking, can withstand higher temperatures, and is easily incorporated into the cookie dough.[13]

Nutrient Enrichment

Various companies may also add extra ingredients to enrich the nutritional value of their product, and some of these ingredients can affect the properties of the cookies. For example, many flours contain riboflavin, which provides a brown color to the final product.[10] Dried apples are used by companies to increase the fibre content and antioxidant nature of the cookies. However, it is important to consider the amount of additional fibre added, as it can add to the firmness of a cookie’s texture.[14]

Manufacturing Process

The mass production of commercial chocolate chip cookies is remarkably similar to the process of making home-baked cookies, but on a much a larger scale. First, we put all the ingredients for making the dough into a large tank. The ingredients that we use to make soft-baked chocolate chip cookies are similar to regular chocolate chip cookies. However, we must use cake flour instead of all-purpose flour; shortening instead of butter; brown sugar instead of white sugar; and add more eggs to create the soft-baked quality.[15] We put the dry ingredients first: such as flour, baking soda, sugar, and chocolate chips. Then, add butter or shortening, vanilla extract, and eggs. Some manufacturers prefer to use the solid form (powder) of eggs and milk. This chief reason for this may be because the solid form can be stored for a longer time than its liquid counterpart. Once all the ingredients are added, the tank tilts upwards for a quick mixing. Once it is well mixed, the dough is transferred into a large machine tank with two feed rollers. These rollers turn to pull the dough into an automated depositor and push it out through openings of the proper shape and size. [16] Once the dough is through the opening, a wire slices the dough. Simultaneously, a conveyer advances a baking tray to pass underneath the depositor. The sliced dough falls onto the tray as it passes below.

At the next station, chocolate chips (or chocolate chunks if preferable), are put into a funnel with a turning gear, which drops chocolate chips on top of the dough. A bar is placed above the conveyer to spray filtered air to blow any strayed chocolate chips from the tray, before it enters the gas oven.[16]

The conveyer continuously moves the trays through the oven. The oven has open ends and dampers to retain the heat. It is important to maintain the consistency of the temperature as temperature differences may cause the cookies to have an inconsistent bake, causing the outside and inside of cookies to be baked unevenly.[17] Alternatively, the trays can be put in a large oven and baked in batches. Trays are placed into an oven for several minutes until they are a golden brown color and the right texture achieved. The duration the dough is put in the oven is relatively shorter for soft-baked cookies than for regular cookies. We want to avoid over baking because the longer we expose the dough to high temperatures, the more moisture will be drawn from the cookies, causing a crisp rather than soft texture.

The tray cools for a few minutes, and when the cookies are still warm, it goes through a chilling process (sprayed by filtered cold air) to prevent condensation in the packaging and to prevent mold growth.[18] The cookies are then packaged, cartooned, and distributed. There are several types of packaging involved. If the packaging is in a box, the worker will examine the cookies one by one and put it in a box. Then the machine parcels up the snacks and puts the plastic cookies trays into a sleeve of metallic film and seals both ends. Alternatively, the packaging process can be done automatically. A robot hand will pick up several cookies and stack them inside a paper bag, which is then sealed at the ends. The bag usually has an aluminum lining inside to protect the cookies from moisture; this is also similar to the function of the sleeve of metallic film for the packaging in the former method.[19]

Preservatives and Storage

It’s no secret that the best kind of cookies are the ones that Grandma makes – chocolate chip, soft and chewy, just out of the oven. They’ll fill your heart with joy when the weather is gloomy or when you just need a hug bundled in cookie dough. But after a couple of days, those (few!) cookies remaining in the cookie jar will have staled into crumbly hard biscuits that even milk cannot salvage. What causes these home-made pieces of heaven to spoil while the store bought cookies stay fresh, neatly in their packages for weeks, maybe even months at a time? How do big cookie corporations create such delicious cookies, while also keeping them soft and fresh for extended periods of time?

The answer? They use different kinds of preservatives! A preservative is an organic or artificial substance that preserves or has the ability to preserve materials and protect against decay and undesirable microbial growth and chemical reactions.

Leavening Agents

Leavening agents are substances that function to lighten, increase shelf life, expand and soften dough or batters.[20] They perform foaming actions within the dough/batter by incorporating gas bubbles either mechanically, by chemicals releasing CO2 by-products or via other chemicals reacting with moisture, heat, acidity etc and producing gaseous by-products[20]. When flour (starch) and water mix, they form a complex matrix that is supported by various proteins, polysaccharides and gluten.[21] The leavening agents work to deposit air bubbles within the matrix so when it sets and gelatinizes, the holes created by the air bubbles will remain.[22] When starch is heated with water, it obtains a soft and pliable nature as the starch molecules absorb water, as known as gelatinization.[3] However, during storage after gelatinization, especially under mildly low temperatures (like refrigeration) the starch molecules undergo a phenomenon called retrogradation. This is when starch molecules realign themselves into a crystalline structure and "squeeze" out the existing water within the starch complex, which can lead to staling.[3] Leavening agents are used to increase shelf life by disrupting the starch/water matrix and delay starch retrogradation. The most common type of leavening agents are Sodium Bicarbonate (baking powder), Ammonium Bicarbonate and yeast. These can all be found right in your kitchen![23] Leavening agents are known to have been used throughout history. Ancient Egyptians have used yeast in baking since 5000 years ago and ancient Mexicans used to describe yeast as "almas" (which translates to spirit) to describe it’s soulful like function in making dough rise.[23] According to an experiment by David Manthey, comparing different types of leavening agents, dry yeast produced the most volume and area whereas ammonium bicarbonate caused the highest rising of dough.[24]

Fully Saturated Mono and Diglycerides

Fully saturated mono and diglycerides are a mixture of glycerides attached to 1 or 2 fatty acid chains.[25] They function as emulsifying agents and affect the starch complex-forming abilities, simply known as ‘starch complexing.’ Starch molecules are spherically shaped and when heated, the starch granules will absorb water and swell. As it cools it hardens in a crystalline, helix-like structure. Mono and diglycerides disrupt the helix by irreversibly fusing to the helix structure and preventing starch from recrystallizing. This maintains moisture and softness within the cookie, as well as delaying retrogradation.[26]

Soy Lecithin

Soy Lecithin was first isolated from an egg yolk by the chemist Theodore Gobley in 1846. In 1850, Gobley named the newly found compound Lecithin, which is derived from the greek word Lekithos which means egg yolk. Although lecithin can be found naturally occurring in many other foods such as peanuts or egg yolks, its most abundant form is in soybeans. Soybean crops are also very inexpensive which makes it the most desirable source of lecithin to food manufacturers.[27] Soy Lecithin is a mixture of phospholipids that acts as an emulsifying agent. It has an amphipathic nature due to its hydrophilic, phosphorous head and hydrophobic, fatty acid tails. Soy Lecithin helps to enhance moisture and flow in the dough by emulsifying two immiscible substances (like water and oil) into one homogenous mixture. Certain types of lecithin can also engage in starch complexing by acting similarly to monoglycerides and complexing with starch (disrupting the helical structure) and ultimately retarding the rate of staling.[28]

Whey-Based Ingredients

Whey-based ingredients are popular ingredients within the food manufacturing world because they are relatively inexpensive and are able to easily replace some or all dairy ingredients such as egg or milk products.[29] As well as enhancing the toasting quality, flavor and texture, it also can extend the shelf life of baked goods.[29]At high temperatures during the baking process in areas of high gelatinized starch, whey protein chains are able to disrupt and weave through the starch chains.[30] This delays the rate of retrogradation by delaying crystallization of the starch molecules.[30] Whey-based ingredients also have water-binding abilities which lowers water activity, thus decreasing microbial growth.[30]

Cookie Storage

To store commercially baked cookies (to elaborate on the packaging techniques mentioned above in the manufacturing process), manufacturers have to ensure the baked cookies are completely cool before packaging and wrapping. Cookies are stored in a container with a tight-fit cover to prevent cookies from drying out. For example, Pepperidge soft baked cookies are packaged in an air tight foil-lined paper container to prevent the drying out of products. The foil-lined paper also helps to reduce the amount of light exposure the cookies receive, which reduces the chance of oxidation since light aids in the oxidative process.[3] Reducing oxidation helps to protect the desirable flavour and prevent rancidity.[3] Wax paper is used to separate layers of soft baked cookies. This can protect fragile cookies from breaking apart and also prevent flavor transferring. Manufacturers label all packages with the name of product, expiry date and all ingredients and nutritional data. Most packaging also contains an attractive illustration of the enclosed cookies as a strategy in marketing.[31]

Government Regulations

According to the Food and Drug Regulations in Canada, soft-baked cookies are required to fulfill the core labeling requirements: common name, net quantity, name and address, list of ingredients, date marking, and nutrition labelling bilingually.[32] These requirements must appear on the food package in a legible manner and in an appropriate location. An example illustrating the labelling requirements is outlined below, using Pepperidge soft-baked Montaukz: Milk Chocolate.

| Requirement | Definition | Example |

|---|---|---|

| Common name | The name which the food is commonly known[32] | Soft Baked Montauk-milk chocolate |

| Net quantity | Amount of food[32] | Serving Size 1 cookie (31g/1.1oz) |

| Name and address | Name and address identifies the responsible party[32] | Pepperidge Farm INC

Norwalk CT 06856 Baked in USA |

| List of ingredients | Ingredients listed in descending order of proportion and allergy statement[32] | Made from: Unbleached Enriched Wheat Flour……Leavening (baking soda) and Salt |

| Date marketing | Anticipate amount of time that unopened food product will retain its freshness, taste or appearance [32] | Best before 02-20-2013 |

| Nutrition Labeling | Nutrition Fact table provides information about nutrient content of food (eg energy, 13 core nutrients)[32] | Total fat 6g-9%

Cholesterol 10mg-3% Protein 1g |

| Bilingual | Labeled in both languages: English and French[32] | Valeur nutritive, Lipides, Glucides |

Some ingredients were exempted from the declaration list of ingredients prior to August 4th, 2012.[33] With the enforcement of Canada’s new food allergen labeling regulation, dated August 4,2012, all pre-packaged products, including soft-baked cookies, must include food allergens, gluten sources and sulphites in the list of ingredients.[34] An example of food allergy information on food labels might be “Product may contain trace of nuts and milk” or “This product is made on equipment that processes peanuts and tree nuts”.

This act establishes an effective control to minimize potential food-related allergic reactions, and increase the protection and awareness of the food-production process for people suffering from food allergies and celiac disease.

Differences between Home-Baked and Manufactured Soft Baked Cookies

Differences between Home-Baked and Manufactured Soft-Baked Cookies

To exemplify the differences between home made soft-baked cookies and manufactured soft-baked cookies, Pepperidge Farm Soft Baked Sugar Cookies were used in comparison to a common, generic soft-baked sugar cookie recipe found in any cook-book.

Table 1.1

| Ingredient | Home-Baked | Manufactured |

|---|---|---|

| Flour | White Flour | Unbromated Unbleached Enriched |

| Sugar | White Sugar | White Sugar |

| Oil | N/A | Vegetable Oil, Canola Oil |

| Fructose | N/A | Fructose |

| Butter | Plain Unsalted Butter | Plain Unsalted Butter |

| Eggs | Plain Eggs | Eggs Whole |

| Milk | 2% White Milk | Non-Fat Milk |

| Corn Syrup | N/A | Corn Syrup |

| Leavening | N/A | Leavening |

| Salt | Table Salt | Salt |

| Rice Starch | N/A | Rice Starch |

| Flavors | N/A | Flavors Natural |

| Pectin | N/A | Pectin |

| Wheat Gluten | N/A | Wheat Gluten |

| Sodium Stearoyl Lactylate | N/A | Sodium Stearoyl Lactylate |

| Datem | N/A | Datem |

Table 1.1 depicts the ingredients used in soft baked cookies from a home recipe as well as those used in manufactured soft-baked cookies. Manufactured soft baked cookies are comprised of an appreciably higher amount of ingredients than home baked cookies. This can be attributed, in part, to the fact that manufactured cookies require additional ingredients to act as preservatives since they must be maintained for a longer period of time prior to being consumed. Soft-baked cookies are considered semi-perishable.[3] The preservatives added, as previously mentioned, will help protect the cookies from reactions such as retrogradation, which could cause them to become stale in a short period of time.[3]

Preference for home baked or manufactured soft-baked cookies is a personal choice. Table 1.2 outlines the advantages and disadvantages of manufactured and soft-baked cookies.

Table 1.2

| Home-Baked Cookies | Manufactured Cookies | |

|---|---|---|

| Advantages |

|

|

| Disadvantages |

|

|

Table 1.2 outlines the advantages and disadvantages of manufactured and soft-baked cookies.

Controversial Additives In Soft-Baked Cookies

The only found additive in manufactured soft baked cookies to be surrounded by some controversy is high-fructose corn syrup. High-fructose corn syrup has been linked to diabetes and high cholesterol in studies involving animals.[35] It has been suggested to be linked to diabetes in children.[35]

Conclusion

The main goal of this wiki was to educate others on the differences between home-baked and general commercially manufactured soft-baked chocolate chip cookies. There are many different types of chocolate chip cookies: crispy, soft, gooey etc., and different ratios of the ingredients are used to yield these different textures. Through thorough exploration of the history, characteristics, ingredients, manufacturing/baking processes. additives and preservatives, we have efficiently contrasted and compared home-baked and commercially manufactured soft-baked chocolate chip cookies. It may come as a surprise to you, but it is very easy to bake your own soft-baked chocolate chip cookies at home. However, the major difference between making and buying cookies is the storage life. The mass production process of the soft-baked cookies that we buy in stores is actually similar with what we have in our home-made cookie recipe. In addition to the ingredients that we use at home, several additives and preservatives are added to commercially manufactured cookies to enhance the nutrient content and maintain the shelf stability. Also, the manufacturing companies have ensured that the packaging of the cookies are able to support the longer shelf lives the cookies offer. This is done by producing air-tight containers, and usually lining the insides with foil-lined paper to minimize light exposure and prevent oxidative rancidity of the cookies. These packaging measures ensure that the flavour and the texture of the cookies will be maintained longer than home-made cookies. Despite the controversies about the usage of additives and preservatives in commercially-baked cookies, the decision to eat the commercially-baked cookies is again, based on your own preferences. The cookie manufacturers are obligated to fulfill the safety standards, as regulated by Health Canada, before they can sell their products to the public. The amount of preservatives used are carefully regulated to ensure safety when consumed. Commercially-baked cookies are also more convenient to buy since they last significantly longer than home-made cookies, however, baking your own cookies allows you to control the amounts and types of ingredients that are used.

Exam Question

Choose the best answer and explain: "What extends the shelf life and softness of commercially soft baked cookies?"

- The soft-baked cookies contain fully saturated mono and di-glyceride fatty acids

- The soft-baked cookies contain a mixture of fully saturated and unsaturated mono and di-glyceride fatty acids

- The soft-baked cookies are made with a type of flour that contains a lot of gluten protein

- Storing the soft-baked cookies in an open top cookie jar right by a window

Correct Answer: The soft-baked cookies contain fully saturated mono and di-glyceride fatty acids. These fats are used to preserve the softness of the cookies by delaying retrogradation. During the baking process, the starch granules start to gelatinize as they absorb water. As the starch granules begin to cool, they start to realign themselves into a crystalline structure. The fully saturated mono and di-glyceride fatty acids act to prevent retrogradation by fusing into the structure and disrupting the crystal lattice!

References

<references>Tbelcn et al., Ray J. “Cooked, Chemically-Leavened Food Laminates.” Patent 3250626. 10 May 1966.

- ↑ 1.0 1.1 1.2 1.3 Stradley, Linda. "History of Cookies - Cookie History." History of Cookies, Cookie History, All about the History of Cookies. What's Cooking America, 2004. Web. 25 Mar. 2013. <http://whatscookingamerica.net/History/CookieHistory.htm>.

- ↑ 2.0 2.1 Block, Stephen. "The History of Cookies." Food History. The Kitchen Project, 16 Jan. 2006. Web. 25 Mar. 2013. <http://www.kitchenproject.com/history/cookies.htm>.

- ↑ 3.00 3.01 3.02 3.03 3.04 3.05 3.06 3.07 3.08 3.09 3.10 3.11 Chan, Judy. FNH 200. University of British Columbia. (2012)

- ↑ 4.0 4.1 4.2 Moiraghi, Malena, Esther de la Hera, Gabriela T Perez, and Manuel Gómez. "Effect of wheat flour characteristics on sponge cake quality." Science of Food and Agriculture 93.3 (2013): 542-549. Cite error: Invalid

<ref>tag; name "Moiraghi" defined multiple times with different content - ↑ Morgan, D. A. . "Smoke, fire, and flash points of cottonseed, peanut, and other vegetable oils." Oil and Soap 19.11 (1942): 193-198.

- ↑ 6.0 6.1 This, Hervé. Molecular gastronomy: exploring the science of flavor. New York: Columbia University Press, 2006. Print. Cite error: Invalid

<ref>tag; name "Hervé" defined multiple times with different content - ↑ Beck, Margit , Mario Jekle, and Thomas Becker. "Sodium chloride – sensory, preserving and technological impact on yeast-leavened products." The Boston Globe 47.9 (2012): 1798-1807.

- ↑ 8.0 8.1 8.2 8.3 Mendelsohn, Simon. Baking Powders. New York: Chemical Publishing Co., Inc., 1939. Cite error: Invalid

<ref>tag; name "Simon" defined multiple times with different content - ↑ Schlichtherle-Cerny , Hedwig , Felix Escher, and Silvia Mallia. "Aroma-active compounds of butter: a review." European Food Research and Technology 226.3 (2008): 315-325.

- ↑ 10.0 10.1 Emerton, Victoria. Food colours. Surrey, UK: Leatherhead Pub. ;, 2008.

- ↑ Levitt, Jonathan. "Cinnamon." Boston Globe 3 Aug. 2006, 3 ed.: D.3.

- ↑ "Food and Drug Regulations." Justice Laws Website. Canada Government, 20 Mar. 2015. Web. 26 Mar. 2013.<http://laws-lois.justice.gc.ca/eng/regulations/C.R.C.,_c._870/page-69.html?texthighlight=semi-sweet+chocolate#s-B.04.006>.

- ↑ Afoakwa, Emmanuel Ohene , Mark Fowlerb, Alistair Patersona, and Joselio Vieirab. "Characterization of melting properties in dark chocolates from varying particle size distribution and composition using differential scanning calorimetry." Food Research International 41.7 (2008): 751-757.

- ↑ Rupasinghe, H.P. Vasantha , Laixin Wang, Gwendolyn M. Huber, and Nancy L. Pitts. "Effect of baking on dietary fibre and phenolics of muffins incorporated with apple skin powder." Food Chemistry 107.3 (2008): 1217-1224.

- ↑ , Moncel, Bethany. "Cookies - Soft Vs Crispy." About.com Food Reference. About.com, n.d. Web. 2 Mar. 2013. <http://foodreference.about.com/od/Tips_Techniques/a/Cookies-Soft-Vs-Crispy.htm>

- ↑ 16.0 16.1 , Youtube: How It's Made Muffins.<http://www.youtube.com/watch?v=CSzVo4Si24U&list=PLC878838A99A30A84>

- ↑ , Hillebrand, Mellisa. "Baking Management." Maintaining Efficient Cookie Production. Penton, 1 Sept. 2006. Web. 27 Feb. 2013.<http://baking-management.com/equipment/bm_imp_14487/>

- ↑ , Youtube: How It's Made Fig Cookies<http://www.youtube.com/watch?v=qwJ1CgSV1qM&list=PLC878838A99A30A84>

- ↑ , "Paper Bags." Standuppouches.com. Stand Up Pouch, n.d. Web. 9 Mar. 2013.<http://www.standuppouches.com/paper-bags/>

- ↑ 20.0 20.1 Joslin, Robert P., et al. “Refrigeration of Doughs and Batters Including as a Leavening Component Dicalcium Phosphate Dihydrate.” Patent 2810650. 22 Oct. 1957

- ↑ Douaire, Phillipe, et al. “Method for preparing leavened dough or leavened puff pastry food products.” Patent 6419965. 16 Jul 2002

- ↑ Gökmen, Vural., Açar, Özge Ç., Serpen, Arda., Morales, Francisco J., “Effect of leavening agents and sugars on the formation of hydromethylfurfural in cookies during baking.” European Food Research and Technology 226 Mar. 2008: 1031-1037. Springer-Verlag. Web. 17 Mar. 2013

- ↑ 23.0 23.1 http://homecooking.about.com/od/foodhistory/a/leaveninghistry.htm

- ↑ http://www.orbitals.com/self/leaven/index.html

- ↑ Corma, A., Ilborra, S., Miquel, S., Primo, J. “Catalysts for the Production of Fine Chemicals: Production of Food Emulsifiers, Monoglycerides, by Glycerolysis of Fats with Solid Base Catalysts.” Journal of Catalysts 173 Jan. 1998: 315-21. Science Direct. Web. 20 Mar. 2013

- ↑ Lauridsen, Jens B. “Food emulsifiers: Surface activity, edibility, manufacture, composition, and application.” Journal of the American Oil Chemists’ Society 53 Jun. 1976: 400-407. Springer-Verlag. Web. 16 Mar. 2013

- ↑ http://www.moleculargastronomynetwork.com/15-additives/Soy-Lecithin.html

- ↑ Van Nieuwenhuyzen, W. “Lecithin production and properties.” Journal of the American Oil Chemists’ Society 53 Jun. 1976: 425-427. Springer-Verlag. Web. 20 Mar. 2013

- ↑ 29.0 29.1 http://www.usdec.org/files/Publications/1BAKERY.pdf

- ↑ 30.0 30.1 30.2 Foegeding, E. Allen, Davis, Jack P., Doucet, Dany, and McGuffey, Matthew K. “Advances in modifying and understanding whey protein functionality” Trends in Food Science & Technology 13 May. 2002: 151-159. Science Direct. Web. 20 Mar. 2013

- ↑ http://www.quakeroats.com/cooking-and-recipes/content/baking-101/cookies/storage-and-freezing-cookies.aspx

- ↑ 32.0 32.1 32.2 32.3 32.4 32.5 32.6 32.7 , CFIA. "Food labeling", CFIA. 17 Apr. 2012. Web. 22 Mar. 2013 <http://www.inspection.gc.ca/english/fssa/labeti/mapcarttxte.shtml>.

- ↑ CFIA. "Food Allergies and Allergen Labeling", CFIA. 07 Jan. 2013. Web. 22 Mar. 2013 < http://www.inspection.gc.ca/food/labelling/core-requirements/ingredients/allergen-labelling/eng/1332352596437/1332352683099>.

- ↑ Health Canada. "Food Allergen Labeling", Health Canada. 20 Aug. 2012. Web. 22 Mar. 2013 < http://www.hc-sc.gc.ca/fn-an/label-etiquet/allergen/index-eng.php>.

- ↑ 35.0 35.1 , CBC News. "Food Safety-Food Additives” CBC.ca n.d. Web. 2 Mar. 2013. <http://www.cbc.ca/news/background/foodsafety/additives.html>

<references>Douaire, Phillipe, et al. “Method for preparing leavened dough or leavened puff pastry food products.” Patent 6419965. 16 Jul 2002

<references>Joslin, Robert P., et al. “Refrigeration of Doughs and Batters Including as a Leavening Component Dicalcium Phosphate Dihydrate.” Patent 2810650. 22 Oct. 1957

<references>Gökmen, Vural., Açar, Özge Ç., Serpen, Arda., Morales, Francisco J., “Effect of leavening agents and sugars on the formation of hydromethylfurfural in cookies during baking.” European Food Research and Technology 226 Mar. 2008: 1031-1037. Springer-Verlag. Web. 17 Mar. 2013

<references>http://www.orbitals.com/self/leaven/index.html (EXPERIMENTAL TEST)

<references>http://homecooking.about.com/od/foodhistory/a/leaveninghistry.htm (most common)

<references>Roy, Soumya, Ray, Madonna M., and Weber, Jean L. "Dough compositions for extended shelf life baked articles.” Patent 20110117244. 19 May 2011.

<references>Chan,,Judy. FNH 200. University of British Columbia. (2012) <references>CFIA. "Food labeling", CFIA. 17 Apr. 2012. Web. 22 Mar. 2013 <references>CFIA. "Food Allergies and Allergen Labeling", CFIA. 07 Jan. 2013. Web. 22 Mar. 2013

<references>Schlichtherle-Cerny , Hedwig , Felix Escher, and Silvia Mallia. "Aroma-active compounds of butter: a review." European Food Research and Technology 226.3 (2008): 315-325.

<references> This, Hervé. Molecular gastronomy: exploring the science of flavor. New York: Columbia University Press, 2006. Print.

<references>"Food and Drug Regulations." Justice Laws Website. Canada Government, 20 Mar. 2015. Web. 26 Mar. 2013. <http://laws-lois.justice.gc.ca/eng/regulations/C.R.C.,_c._870/page-69.html?texthighlight=semi-sweet+chocolate#s-B.04.006>.