Course:FNH200/2012w Team04 ProcessedCheese

Introduction

Currently, cheese makes up the greatest proportion of dairy consumption in the world. In fact, at 34 percent, it is more frequently consumed than liquid milk, which makes up just 27 percent. Of all the milk produced in the United States, from a cow, sheep or goat, almost one third is used in cheese production. These products differ in their composition in regards to the types of cheese used, their texture, flavour, and any additives used, as well as in how they are presented, which may be as individual slices, blocks, cylinders, or even tubes. [1]

In class, we observed how biotechnology can be applied into food systems, and looked in detail at the biotechnology of cheese With 1/3 of the cheese industry belonging to processed cheese [1], we were intrigued by its production, and decided to look further into this aspect of processed cheese.

Since natural cheese itself undergoes some processing, it may be difficult for some to grasp an understanding of what processed cheese actually is. Thus, one question that must be addressed is, what is processed cheese? And how does it differ from natural cheese in terms of chemical and physical properties, and its production and regulations? To answer these questions, we will explore the functions of emulsifiers and bacterial cultures in cheese, the additional processing steps that producers take in transforming a variety of natural cheese into processed cheese, as well as the regulations that are involved with its production. However, one may not be satisfied with simply examining the steps and standards associated with processed cheese, and may question the purpose of applying additional processing steps to natural cheese nearly 100 years ago, and the implications associated with the additional processing of food. As a result, we will begin by briefly look into strengths and shortcomings of processed cheese in comparison to natural cheese, and follow with its production.

History

Processed cheese was first introduced by Walter Gerber and Fritz Stettler of Switzerland in 1911. During this period, there were difficulties in shipping cheese to areas with hot climates, so they attempted to devise a method that would extend the shelf life of their products. To do this, they shredded and heated Emmental cheese along with sodium citrate, producing a firm product upon cooling. [2] At about this time in the United States, James Lewis Kraft was working on a product that involved the selection of natural cheese, and putting them through a blending and heating process. In 1916, Kraft began selling melted and stirred pieces of Cheddar cheese packaged in glass jars and cans. [2]

What Exactly is Processed Cheese?

Processed cheese is essentially "cheese made from cheese." [3] In addition to the four basic steps associated with the production of natural cheese (coagulating, draining, salting and ripening), the manufacturing of processed cheese involves the additional steps of cleaning, blending, and melting.[1] This is achieved using heat, mechanical sheer, and emulsifying salts. This contributes to the formation of a stable and homogeneous product, uniform in flavour and texture. Additional ingredients such as emulsifiers, spices and herbs may also be added to produce a greater variety of products.[4]

Natural Cheese vs Processed Cheese

Aged Chedder Cheese is an example of a natural cheese, while American cheese is a type of processed cheese

This video shows the difference between natural cheese and processed cheese

Strengths and Shortcomings

Strengths:

- Reduces refrigeration cost during storage and transport, especially important in hot climates[5]

- Longer shelf life: Usage of heat during the manufacture of processed cheese results in a “physico-chemically and bacteriologically” stable product with an enhanced shelf life [4]

- Lower production cost; economical to manufacture: can be made from whey, skim milk powder, and lower-grade natural cheese [4]

- Better keeping quality, with less changes during storage[5]

- It can have a long shelf life without spoiling if refrigerated [6]

- If unopened, it does not necessarily need to be kept in cold [6]

- Adjustable packaging for various usages [5]

- Suitability for home use and for snack restaurants e.g. in cheese burgers, spreads and dips for fast foods. [5]

Shortcomings and Safety Concerns:

- Possible health implications with the use of artificial colors/flavours and chemicals such as potassium phosphate (which may lead to dizziness, irregular heartbeat, cramps and numbness, among others) and tartrate (associated with diarrhea, headache, heartburn, stomach pain and other symptoms).

- Associated with trans-fat.

- Contains increased levels of salt

- Mild and smaller range of flavors

Above information retrieved from[5]. and [7]

Chemical and Physical Properties

Physical Properties

Processed cheese comes in vacuum packaging that contains slices of cheese. Some of these are packed individually in wrappers for convenience during usage. [8]The colour of cheese depends on what kind of cheese was used during processing e.g. Swiss, cheddar, mozzarella).

Emulsion

The making of cheese involves an oil-in-water emulsion. These cheese products consist of an oil phase that contains fats and oil-soluble substances, and a water phase that contains water-soluble proteins and minerals. The surface-active proteins (usually are caseins) are soluble in oil and water phases and this causes the proteins to collect at the interfaces between the two to create an emulsion. The efficiency of emulsions to prevent phase separation affects the size of droplets. As emulsification improves, droplets get smaller and surface area increases until it reaches homogenization. [9]

In processed cheese, emulsions function slightly differently. Instead of fat that is found in discrete droplets, fats in processed cheese form a semi-continuous phase throughout the protein gel. The stability of emulsion is controlled by absorbed caseins or hydrolyzed casein functions. [10]

Emulsion affects the smooth texture of processed cheese. The structure and texture of processed cheese is linked with the size and distribution of fat globules in cheese. If fat in processed cheese is weakly homogenized, large fat droplets form and the cheese becomes soft and melts easily while small fat droplets are small and causes the cheese to be hard and non-melting. [10]

Emulsifying Salts

Emulsifying salts not only provide an uniform structure during the melting process but also are used to supplement the emulsifying capability of cheese proteins during manufacturing. This is obtained when calcium is removed from the protein system and thus emulsifies fat to stabilize the emulsion. The use of emulsifying salts such as disodium phosphate and trisodium citrate in processed cheese manufacturing aids in improving the emulsification properties of caseins by displacing the calcium phosphate complexes in the insoluble calcium-parcaseinate phosphate network present in natural cheese. [11]

In processed cheese, emulsifying salts are used to affect the physio-chemical properties (texture profile, degree of casein dissociation, fat particle size, color, and nuclear magnetic resonance profile (NMR)) of processed cheese. As concentration of emulsifying salts increase, the degree of casein dissociation, hardness, and pH also increases. The specific type of emulsifying salts used affects the fat particle size of processed cheese with sodium hexametaphosphate yielding the largest particles compared to others. [11]

Casein in Processed Cheese

Emulsifying proteins used in cheese are casein and casein fragments. Caseins contain calcium phosphate groups on one end which are water-soluble. Calcium also influences solubility of the emulsification. When more calcium is involved, the protein becomes less soluble. As a result, the degree of emulsifying of the proteins will also decrease.

In processed cheese, intact casein is used. Recent research has shown that intact casein level influences the quality and efficiency of processed cheese. The percentage of intact casein influences physical properties of processed cheese, specifically viscosity, firmness and fracture stress.[12]

Production and Processing

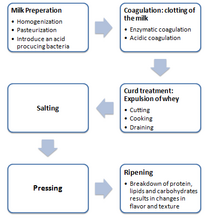

Natural cheese

Since natural cheese is the main ingredient of processed cheese, in order to better understand the production steps behind processed cheese, it is important to first appreciate the steps taken in the production of natural cheese.

Milk Preparation

First of all, milk has to be prepared for cheese production. Milk is homogenized to make fat level constant. A centrifuge is used to obtain the appropriate fat levels for different kinds of cheese. After homogenization, the milk is now ready for pasteurization to destroy any harmful bacteria.

Pasteurization

The Food and Drugs Act and Regulations recognize two types of cheese in regards to milk heat treatment. These are: pasteurized milk and raw milk. [13]

Pasteurization is the act of heating food at a high temperature for a short amount of time; usually it is heated at a temperature of at least 72°C for 15 seconds [14]. The goal of this process is to reduce the number of microorganisms in the food content. While pasteurization is considered the safest heat treatment that can be applied to cheese, it can result in several negative effects to the final cheese product:[13]

- Denaturation of whey protein

- Lowered levels of curd formation

- Poor moisture release

- More coarse texture, with a decreased flexibility

If cheese is made with raw milk (ie. milk that has not undergone heat treatment), by law, it must be kept at at least 20°C for 60 or more days from when it is manufactured for it to be considered safe for consumption. [13]

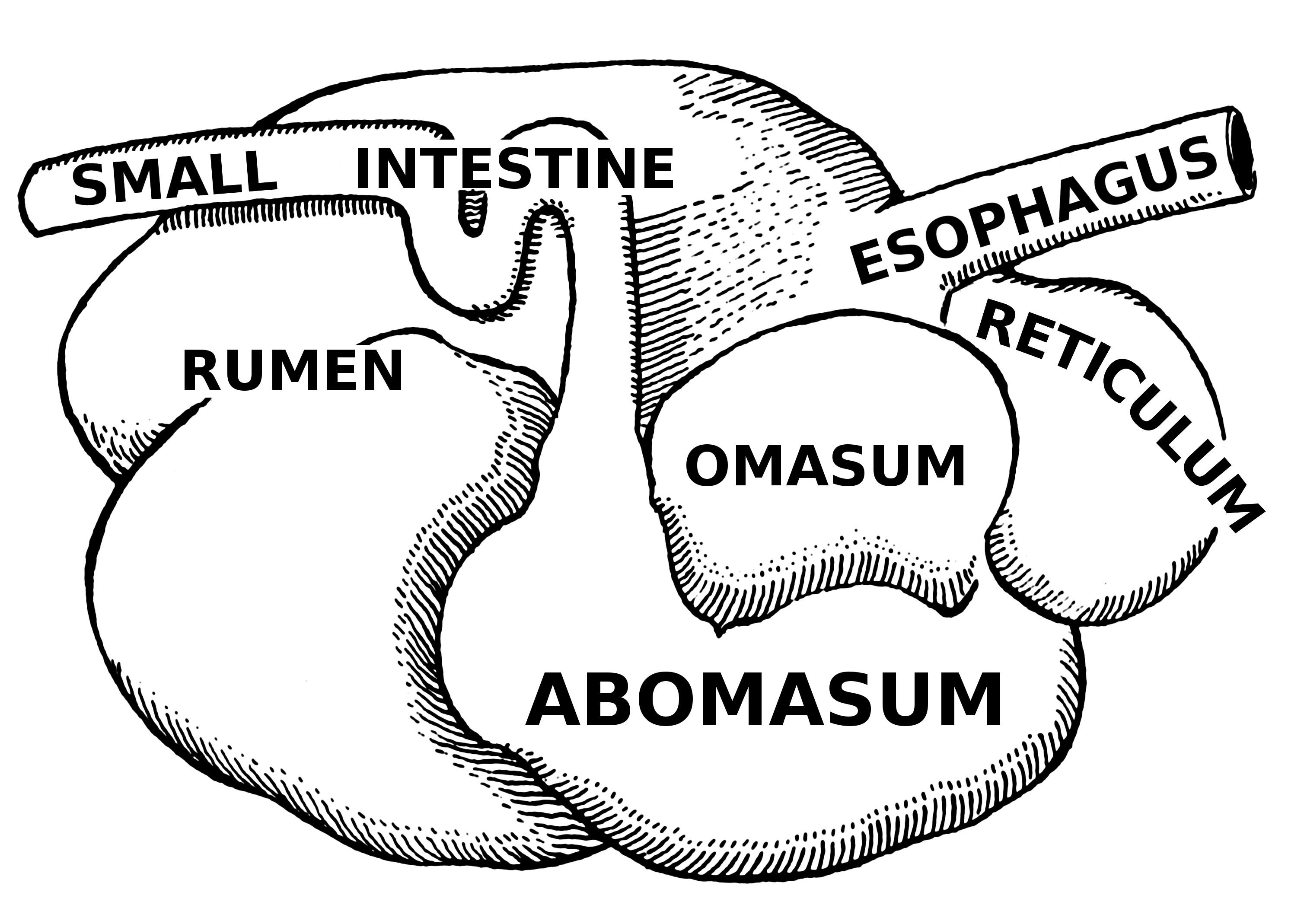

Coagulation and Fermentation

After the process of pasteurization comes fermentation. Biotechnology involves the use of "good" microbial cultures by humans for a specific purpose, such as fermentation in food production. In cheese, fermentation promotes the clotting of milk (coagulation), and is achieved by the addition of starter bacterial cultures. The bacterial cultures are added to the pasteurized milk, and heated at 32°C for 30 minutes, during which ripening occurs, and the bacteria begins to grow and ferment.[15] As the lactose in the milk is converted to lactic acid by the starter culture, calcium caseinate is transformed into casein. Once the pH of the milk drops, and establishes mildly acidic conditions, rennin is added. [1] While rennin is naturally found in the fourth stomach of a calf along with a mixture of gastric juice and salt, some bacterial cells have been genetically modified to produce this enzyme.[16] Rennin initiates the formation of a curd by hydrolyzing parts of the k-casein which makes up the casein micelle. These micelles, which are normally calcium-stable, become sensitive to calcium, and leads to coagulation in the presence of the lactic acid. [16] The solid part of milk called curd, is now a separate entity from the liquid part which is mostly comprised of the whey. While most of protein and fat of milk remain in the curd, all of lactose, minerals, proteins and vitamins are retained in the whey. [1] Note that it is important that the curd remains undisturbed for at least 30 minutes once rennin is added to allow the formation of a firm coagulum. [15]

Some of the benefits of fermentation include:

- It assists coagulation. (Causes lower pH which results in faster coagulation)[13]

- It promotes syneresis which is a means of controlling moisture content. [13]

- It helps to prevent the growth of pathogenic and spoilage bacteria. [13]

- It develops optimal cheese texture, flavour and colour. [13]

- Consumption of microorganisms involved in fermentation may be beneficial to the human digestive system. [16]

Curd Treatment

After curd is formed, it is cut into smaller pieces to speed up whey expulsion and increase the surface area. Cutting the curd into small cubes reduces moisture content of the curd. Curd that has been cut is now cooked to contract the curd particles, remove whey, develop texture and to control moisture. Different temperatures of cooking are used for different varieties of cheese. For example, cheddar cheese curds are cooked at 37.8 °C. After the curds are cut and cooked, they are now knitted to allow the accumulation of lactic acid. Knitting is especially important in developing characteristic texture of different varieties of cheese. For example, a bean gum is added to cream cheese to stiffen, and a creaming agent is added to cottage cheese.

Salting

After this process, cheeses are salted; either coarse salt is spread around the cheese or the cheese is immersed in a salt solution. Salting affects different factors such as rind formation, microorganisms and enzyme activities. Again, salting method and salt percentage differ by kinds of cheeses.

Pressing

Next step is pressing, and it decides the shape of cheese. It is done by confining curds in a cloth bag. With some cheeses, vertical pressing is often use. Others require vacuum pressing.

Ripening

Final stage is ripening. During this stage, varieties of cheeses acquire their characteristic textures and flavors through physical and chemical changes. These are controlled by temperature, humidity and period of time dedicated to ripening. Ripening allows bacteria to transform the curd into a cheese.

Above information retrieved from [1] and [17]

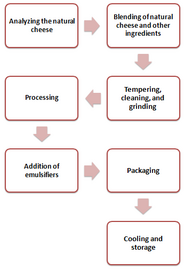

Processed Cheese

In addition to the above processes associated with natural cheese, the production of processed cheese includes the following steps:

Analyzing

The making of processed cheese starts with the selection of normal cheese, such as Cheddar or Colby (mostly used in the United States) [1], which will later be processed. Most processed cheese are made from the mixing of one, two or more varieties of cheese (with some exceptions such as cream cheese, cottage cheese and skim milk cheese) [19] causing the flavor to vary from one processed cheese to another.

Each block of cheese that is received is sampled and analyzed for their acidity, fat content, moisture, and salt, among other properties, which will all play a role on the characteristics of the end product.[18]

Blending (of Natural Cheese and Other Ingredients)

To make processed cheese, heating of the natural cheese until it is liquefied is a crucial step. That step must be achieved perfectly in order to destroy the vegetative cells present [20]. In order to see the light of this important step, it will be discussed in great detail below.

In this step, natural cheese with varying age groups, acidity, pH, texture, and composition are melted and blended together. Upon selection, the proper amount of emulsifier must be added in order to create a homogenous batch, which will later result in a processed cheese; this is based on the analysis of the fat and moisture content [1].

The final product is typically composed of 75% of cheese that have been ripened for 0-3 months, and the remaining 25% made of cheese that have been ripened for 6-12 months. As a guideline, highly sour cheese is limited to forming 5%, and gassy cheese to forming 2% of the total cheese product.[18] In addition to the natural cheese, other ingredients such as preservatives, coloring agents, flavouring agents, spices, salt, and mould inhibitors are added to the blend in order to produce a desired final product. [21] However, the addition of salt in this process does create many complaints amongst consumers.

Addition of Other Ingredients and Food Additives

- In order to increase the shelf life of processed cheese, preservatives such as lactic acid and monolaurin are added. This increases shelf life from 10 days to 35 days.

- Sodium citrate functions as an acidity regulator, and often added to processed cheese to regulate acidity, and buffer any pH changes.

- GDL, which stands for Glucono delta Lactone, is also used in processed cheese to reduce the pH.

- Maltodextrin is one of the bulking agents, and it can be added to processed cheese to reduce sweetness in flavour. When bulking agent is added, extra stabilizer such as carrageenan is added as well.

- Annatto is the most commonly used colouring agent that is added to processed cheese to create a variety of hues from light yellow to orange red. Certain herbs are also added to create good colour and texture.

- Lecithin, a protein extracted from egg yolk, is used as an emulsifier and also as an anti-stick processing aid.

- In some occasions, nicin is added as a preservative, but with a pH above 5, potassium sorbate or sorbic acid is the usual choices of preservatives.

- Some manufacturers choose to add minerals to processed cheese. These minerals are often calcium carbonate or calcium citrate.

- Combination of carrageenan and alginate is used specially for processed cheese to reduce in dairy solids without losing texture and structure. The combination of two gums also increases the firmness of processed cheese, resulting in ease of slicing and grating.

Above information retrieved from[23]

Tempering, Cleaning, and Grinding

From the curing room, the cheese sits in the blending room for up to 48 hours until it reaches room temperature. By reaching room temperature, the cheese is softened, and will help in the cleaning, cutting, and grinding processes to follow. Cleaning involves the removal of inedible sections of the cheese prior to processing. These sections, as well as the outer layer which includes the paraffin wax, is scraped off and removed from the cheese. The cheese is first cut into four pieces in a process called quartering, and then placed in a grinder which grounds it into small pieces. The grinding ultimately aids in the production of a homogeneous final product.[18]

Processing: Heating and Stirring

Processing involves stirring the cheese, and passing it through a continuous cooker, which will heat the product to 130 to 150°C (265 to 300 °F) for two to three minutes [1]. Another method involves heating it in a kettle via direct steam injection (the primary heating method applied in the production of processed cheese)[21] for 5 minutes at 65°C, and then further heated at 80°C for 10 minutes to enhance shelf life and to achieve further destruction of microorganisms.[18] Factors such as cooking time, temperature, mixing speed, and the rate at which the cheese is cooled has a significant role on the texture of the final product. Therefore, those factors must be closely monitored during the processing process in order to avoid thickening and browning .[21]

Addition of Emulsifiers

After heating and stirring, the cheese is then separated into two phases: fat and serum [1]. Emulsifiers are then added to form a consistent and smooth texture by disseminating the fat, as discussed above.

Packaging

As soon as the above processes are done, the cheese is removed from the cookers and headed for packaging. The packaging process is done in anaerobic conditions leaving limited opportunities for the growth of moulds [1]. As for sliced cheese such as Kraft single slices, the cheese is spread by chilled steel rollers after heating and is cut by rotary knives into different thicknesses to suit different consumer choices [1].

Labeling Requirements and Regulations

Labeling Requirements

There are many labeling requirements for processed cheese products that must be met by manufacturers. These requirements are set out in the Food and Drugs Act and Regulations and are enforced by The Canadian Food Inspection Agency, or CFIA. Firstly, manufacturers must meet the basic labeling requirements for all products as stated in the Food and Drugs Act and Regulations. All information on processed cheese food labels must not be deceptive and be easily read by consumers.

The labels must have all mandatory information presented in both French and English, except for the name and address of the person responsible for the product. Although the name and address can be in either French or English, it is also a mandatory component that must appear on the label.

Below are mandatory components of the label that must appear in both English and French.

1) Processed cheese labels must contain the common name, which is usually “processed cheese products,” on the front of the package.

2) The label must contain the net quantity of the entire package of processed cheese, usually expressed in grams.

3) A nutrition facts table must be present on the label. It must provide information on the amount of energy and the amount of fat, saturated and trans fats, cholesterol, sodium, carbohydrate, fiber, sugars, protein, calcium, iron and Vitamin A and C contained per serving of the stated size. The serving for processed cheese appears on the top of the nutrition facts table.

4) All processed cheese products must contain a list of ingredients on the label. The ingredients must be listed in descending order of proportion by weight. Any ingredients of ingredients, such as milk, modified milk ingredients, salt, bacterial culture, microbial enzyme, calcium chloride, colour, and lipase that make up cheese must be listed in parentheses following “cheese” in the ingredients list.

5) The durable life date must be stated on the label. Usually, storage instructions will also appear but are not required. Since processed cheese does not have a storage life of more than 90 days, a durable life date must be printed on the package and the words “keep refrigerated” will usually also appear on the package, as determined by each respective manufacturer.

Above information retrieved from[24].

Processed cheese products are classified as standardized cheeses under the Foods and Drugs Regulations and therefore, the labels of the processed cheeses must contain the actual percentage of milk fat and moisture content on the label. As stated in Section B of the Foods and Drugs Regulations, the words “milk fat” or the abbreviation “B.F.” or “M.F.” must appear with the percentage of milk fat declared. The word “moisture” or “water” must appear along with the percentage of moisture declared for the processed cheese product [25]

Optional Nutrient Claims for Labeling

Processed cheese products may contain nutrient content claims on the packaging if manufacturers choose to include them. All nutrient content claims are optional but MUST not be misleading for consumers in anyway [26]. Also, the information conveyed on nutrient content claims must be unified and consistent amongst all processed cheese products, including products made from different manufacturers [26].

Example of Nutrient Content Claim : Kraft Processed Cheese Slices

Most processed cheese slices products contain the nutrient content claim of “source of calcium.” According to the Canadian Food Inspection Agency, a mineral claim is not allowed to be declared on labels unless one serving of the food, which the amount is shown on the top of the nutrition facts table, contains at least 5% of the recommended daily value [27]. As seen on the picture on the right, a "source of calcium" claim is declared on the front of the Kraft single slices package. Under the nutrition facts table, the amount of calcium in one serving, which is 1 slice or 21 g of processed cheese, is 8%. As a result, the claim of a "source of calcium" is therefore valid.

Regulations

According to the Dairy Products Regulations under the Canadian Food Inspection Agency, processed cheese is not required for grading in Canada [28]. However, processed cheese is a standardized cheese product under the Foods and Drugs Regulations and manufacturers must adhere to certain regulations.

1) Processed cheese must be a product made by mixing varieties of cheese and optional ingredients and allowed additives into one homogenous product[29]. The end mixed result must be thermally processed[29].

2) Processed cheese must contain a total cheese ingredient of no less than 51% and along with that, must contain milk ingredients no less than 51% as well[29].

3) Processed cheese must contain no more than 60% moisture. However, low-fat or fat-reduced products may contain up to 65% moisture[29].

Examples of Optional Ingredients for Processed Cheese as Set in the National Dairy Code [29]:

- Milk ingredients and modified milk ingredients

- Salt, vinegar, flavouring agents

- Seasonings, spices

- Permitted food additives

Video and Final Exam Question

Final Exam Question

Question

List the key processes involved in the production of processed cheese from natural cheese and provide a brief explanation for any changes (differences) that is observed in the final product as a result.

Answer

1) Blending of Natural Cheese

Natural cheese with varying age groups, acidity, pH, texture, and composition are melted and blended together

2) Additives/Other Ingredients (Name 1-2 ingredients its function)

- In order to increase the shelf life of processed cheese, preservatives such as lactic acid and monolaurin are added. This increases shelf life from 10 days to 35 days.

- Sodium citrate functions as an acidity regulator, and often added to processed cheese to regulate acidity, and buffer any pH changes.

- GDL, which stands for Glucono delta Lactone, is also used in processed cheese to reduce the pH.

- Maltodextrin is one of the bulking agents, and it can be added to processed cheese to reduce sweetness in flavour. When bulking agent is added, extra stabilizer such as carrageenan is added as well.

- Annatto is the most commonly used colouring agent that is added to processed cheese to create a variety of hues from light yellow to orange red. Certain herbs are also added to create good colour and texture.

- Lecithin, a protein extracted from egg yolk, is used as an emulsifier and also as an anti-stick processing aid.

- In some occasions, nicin is added as a preservative, but with a pH above 5, potassium sorbate or sorbic acid are the usual choices of preservatives.

- Some manufacturers choose to add minerals to processed cheese. These minerals are often calcium carbonate or calcium citrate.

- Combination of carrageenan and alginate is used specially for processed cheese to reduce in dairy solids without losing texture and structure. The combination of two gums also increases the firmness of processed cheese, resulting in ease of slicing and grating

3) Emulsifying salts

Emulsifying salts are used to supplement the emulsifying capability of cheese proteins during manufacturing. Not only does it aid in the improvement of emulsification, but it also adds a saltier flavor to processed cheese.

4) Differences in chemical and physical properties In processed cheese, intact casein is used. Recent research has shown that intact casein level influences the quality and efficiency of processed cheese. The percentage of intact casein influences physical properties of processed cheese, specifically viscosity, firmness and fracture stress.

Video

References

- ↑ 1.00 1.01 1.02 1.03 1.04 1.05 1.06 1.07 1.08 1.09 1.10 1.11 1.12 United States. U.S. Environmental Protection Agency, Office of Air Quality Planning and Standards, and Emission Factor and Inventory Group. Emission Factor Documentation for AP-42 Section 9.6.1 Natural and Processed Cheese. Midwest Research Institute (MRI). July. 1997. Web. 17 Mar. 2013.

- ↑ 2.0 2.1 Michigan State University. 2009. A webpage about Processed Cheese and its history. [online]. Available from https://www.msu.edu/user/mdr/vol14no2/ustunol.html [accessed 17 March 2013]

- ↑ DCI Cheese Company. 2011. A company owned website that addresses frequently asked questions about cheese. [online]. http://www.dcicheeseco.com/about-cheese/faqs [accessed 19 March 2011].

- ↑ 4.0 4.1 4.2 4.3 Indira Gandhi National Open University. 2011. A webpage that discusses the "Principle and Method of Manufacture of Pasteurized Processed Cheese Products (PCPS)". [online]. Available from http://vedyadhara.ignou.ac.in/wiki/images/e/e0/BPVI-16-Block_2-Unit-7.pdf [accessed 17 March 2013]

- ↑ 5.0 5.1 5.2 5.3 5.4 Fox, P. (ed.) 1999. Cheese: Chemistry, Physics and Microbiology: Volume 1: General Aspects Volume 2: Major Cheese Groups. Aspen Publishers Inc, Gaithersburg, Maryland.

- ↑ 6.0 6.1 wiseGeek. A site that answers the question of "what is processed cheese" [online]. Available from http://www.wisegeek.com/what-is-processed-cheese.htm [accessed 23 March 2013]

- ↑ Dovey, C. A food safety website that addresses the question "Is Processed Cheese Yet Another dangerous Fast Food to Avoid?" [online]. Available from http://food-safety.knoji.com/is-processed-cheese-yet-another-dangerous-fast-food-to-avoid/ [accessed 24 March 2013]

- ↑ http://goldenagecheese.blogspot.ca/2012/04/real-versus-processed-cheese.html

- ↑ Burrington, K.J. Understanding Process Cheese. http://www.foodproductdesign.com/articles/2000/02/understanding-process-cheeses.aspx. Feb 2000. Web. 24 March 2013

- ↑ 10.0 10.1 Hartel, R.W. Food Emulsifiers and Their Applications. 2nd ed. 2008, XIV, 426p. 114 illus. ISBN 978-0-387-75284-6

- ↑ 11.0 11.1 Chen, L. and Liu, H. 2012. Effect of emulsifying salts on the physio-chemical properties of processed cheese made from Mozzarella. Journal of Dairy Science, 95 (9): 4823-4830.

- ↑ Henderson, A. The Influence of Intact Casein in Processed Cheese. [online]. Available from https://docs.google.com/viewer?a=v&q=cache:pPa2xSQAkMoJ:www.caseuspro.com/LiteratureRetrieve.aspx%3FID%3D99881+&hl=en&pid=bl&srcid=ADGEESjZnNue_9FwvC_-h8xC_CraT5gZZ66IC-oBaB5M1uBu369lOtb2XzHC9dYwt-jhF8Yg-yzBwK12WCimnJ4slg7bTPGAWf9ioVJcr9eGweBLife9OZOKNusqaYuJp-Jzv9qavXsI&sig=AHIEtbS34N2NbL-DuFX-kRzcR-OLbAHB4g [accessed 24 March 2013]

- ↑ 13.0 13.1 13.2 13.3 13.4 13.5 13.6 13.7 University of Guelph. 2009. A site that covers information on “cheese making technology” [online]. Available from http://www.uoguelph.ca/foodscience/content/dairy-education-series [accessed 18 March 2013]

- ↑ Chan, J. UBC Wiki:Lesson 06. [online]. http://wiki.ubc.ca/Course:FNH200/Lesson_06 [accessed 23 March 2013]

- ↑ 15.0 15.1 Milk Facts. A site that discusses the general production of cheese. [online]. http://www.milkfacts.info/Milk%20Processing/Cheese%20Production.htm [accessed 23 March 2013].

- ↑ 16.0 16.1 16.2 Chan, J. UBC Wiki: Lesson 9. [online]. http://wiki.ubc.ca/Course:FNH200/Lesson_09 [accessed 23 March 2013]

- ↑ Glass, Kathleen., Doyle, M.E., “Safety of Processed Cheese.” Rev of the Scientific Literature. University of Wisconsin-Madison, May 2005.

- ↑ 18.0 18.1 18.2 18.3 18.4 Thenmozhi, K. 2013. A site that provides a step to step explanation of the processes involved in the production of processed cheese [online]. Available from http://www.streetdirectory.com/food_editorials/snacks/cheese/processed_cheese_making.html[accessed 18 March 2013].

- ↑ US Food and Drug Administration. 2012. "CFR - Code of Federal Regulations Title 21.” [online]. Available from http://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=133.169 [accessed 23 March 2013]

- ↑ Canadian Food Inspection Agency. 2010. Dairy Establishment Inspection Manual.[online]. Available from http://www.inspection.gc.ca/english/fssa/dailai/man/estman/ch13e.shtml [accessed 23 March 2013]

- ↑ 21.0 21.1 21.2 Kapoor, R. and Metzger, L. 2007. Process Cheese: Scientific and Technological Aspects—A Review. Institute of Food Technologists, 7: 194-214.

- ↑ Canada. Justice Law, Food and Drug Regulations. Food Additives. 15 March 2013. Web. 17 March 2013.

- ↑ Hawkinswatts. A food production company-owned website that provides information about the function and benefits of ingredients in processed cheese. [online]. Available from http://www.hawkinswatts.com.au/app_dairy8.htm [accessed 26 March 2013]

- ↑ Canada. Canadian Food Inspection Agency. Basic Labeling Requirements. 19 March 2013. Web. 17 March 2013.

- ↑ Canada. Canadian Food Inspection Agency. Cheese - Fat and Moisture Declaration. 20 March 2013. Web. 17 March 2013.

- ↑ 26.0 26.1 Health Canada. Food and Nutrition. Nutrition Claims. 20 March 2013. Web. 17 March 2013.

- ↑ Canadian Food Inspection Agency. Nutrient Content Claims. 20 March 2013. Web. 17 March 2013.

- ↑ Canada. Justice Laws Website. Dairy Products Regulations - Grades and Grade Names. 20 March 2013. Web. 17 March 2013.

- ↑ 29.0 29.1 29.2 29.3 29.4 National Dairy Code. 2005. "Processed Cheese." [online]. Available from http://www.dairyinfo.gc.ca/pdf/National%20Dairy%20Code%20Fourth%20Edition%20%282005%29_e.pdf [accessed 20 March 2013].