Course:FNH200/2012w Team01 Popcorn

Popcorn is known to be a very popular snack among Canadian households. According to The Popcorn Board, North America consumes about 17.3 billion quarts of popped popcorn each year.[1] As a result of such high popularity, manufacturing companies such as ConAgra Foods Canada Inc. are jumping at the opportunity to find ways to selectively breed corn to yield high quality kernels. Moreover, these kernels can be processed in various ways to produce creative snacks that individuals can purchase. There is some controversy, however, about the health risks associated with consuming processed popcorn. As more individuals are becoming aware of additives and preservatives added to some popcorn snacks, questions start to arise: Why do popcorn kernels not spoil at room temperature? How and where is popcorn processed? What are the health benefits to eating popcorn? What are the risks associated with microwave popcorn? Recent research has been done to view the impacts and health benefits of popcorn, specifically microwave popcorn. As the popcorn industry expands, Canadian regulations, processing methods, and trends begin to change. Our group was particularly interested in knowing the method behind popcorn kernel processing and the reason behind the high popularity of popcorn in Canada.

Introduction

Popcorn is a type of maize, scientifically known as Zea mays everta.[2] Only this specific species has the right thickness to allow the whole grain to pop and fluff into two distinct shapes with the application of heat: mushroom and butterfly shape.[3] In terms of color, all popcorn kernels are historically white. However due to selective breeding, yellow kernels started to increase its appearance because of its preferred characteristics (i.e. larger kernels and stronger flavor). Nutritionally, popcorn has little protein, water, vitamins, minerals, and fat and is composed mainly of starch.[3] A cup of puffed popcorn can have as little as 31 calories. [4]

The Popcorn Kernel

Popcorn is a whole grain composed of three components: the endosperm, the germ, and the hull. The endosperm contains starch, protein, some vitamins and minerals; this is where the main source of energy is situated. The germ is where vitamin B, some protein, minerals, healthy oils, and most importantly where the seed for a new plant is found. The hull is the outer shell where vitamin B, moisture, and fibre are located. [4]

History

Popcorn was discovered as early as 4700 BC by the Aztecs.[3]Popcorn was used during Aztec Indian ceremonies for decorating ceremonial headdresses, necklaces and statues of gods. In 1893, the first popcorn popper was introduced in Chicago by Charles Cretors.[4] After this revelation, street vendors were selling popcorn left and right. In 1949, the microwave popcorn was introduced by Percy L. Spencer. There was a problem, however: the microwave weighed 750 lbs and was 1.68m tall. It took decades for microwaves to be placed in Canadian homes. In 1973, Lawrence C. Brandberg and David W. Andreas, two scientists at Pillsbury, invented packages for microwavable popcorn. [4] The only problem was, this new invention was not shelf-stable and had to be placed in the refrigerator.[4] In 1984, ACT II, a shelf-stable microwave popcorn, appeared and was the first mass-marketed microwave popcorn.[4] It was manufactured by Golden Valley Microwave Foods (GVMF) in Minnesota, now owned by ConAgra Foods.[4] Today, Americans and Canadians consume about 17.3 billion quarts of popped popcorn each year.[1]Much of the popcorn we consume in Canada today is grown in Indiana and imported into Canada.

Types of Microwave Popcorn

There is a variety of microwave popcorn on the market. The most common flavours include Butter Popcorn, Light 94% Fat-Free Popcorn, Sweet and Savoury Popcorn, and Natural Popcorn.[4] As for brands, there are too many to be named. Over 75 brands exist, including individual store brands. You have probably heard of many popcorn brands such as Orville Redenbacher's, 365 Everyday Value, Pop Secret, Jolly Time, ACT II, Black Jewel, Newman's Own, Smart Balance, and the list goes on.

Popcorn Processing

Harvesting

Kernels are revealed when corn husks are peeled during harvesting. Zea mays everta in particular have larger kernels than other types of corn. During harvesting, popcorn has a moisture content of around 16-20%.[5] To bring down the moisture content to an optimal 14%, the crop enters giant bins with warm air running through to accelerate the process of heat evaporation.[5] This step is crucial because if the kernels have too much moisture, spoilage can occur due to high water availability. On the other hand, if the kernels are too dry, then chances are they will not pop.[5]

Manufacture Processing

The dried ears are transported to a scalper, where the machine strips kernels from the cobs.[5]Through a series of oscillating screens, the vibrating motion removes husk chunks and dirt particles, leaving the kernels to move on to the next step. This purification process is continued onto a gravity table.[5] The kernels are placed in a large tub. The vibration motion and fast air movement upward cause kernels to rise up into the air in different directions. The point of the gravity table is to separate and remove kernels that are too little or too large from the centre.[5] Properly matured kernels are lighter in weight, while the heavier immature kernels are heavier, dropping through the bottom of the separator and recycled for use as seed. As the lighter kernels move to the sides of the table, they are moved aside. The last purification step is to pass through a tube-like machine where kernels shoot vertically at a high velocity. The kernels fly by an electric eye, which detects remaining debris or defective grains to ensure high quality.[5]

Testing and Packaging

A sample of the kernels that have been purified are added into a pot with some oil. As the temperature reaches 446°F, water begins to steam, allowing pressure to build inside the kernel.[5] The kernel then pops, turning inside out and revealing the starchy centre inside. Once all the kernels are popped inside the pot, it is placed into a large tube. To pass an assurance test, the popcorn must expand 44.5 times its original volume.[5] Once passed, the kernels of that batch are transported to the packaging area where, along with measured amounts of salt, soybean oil, and flavoring, are dropped into microwave bags.[5] The bag is not vacuum-sealed, but sealed air tight to prevent moisture in the air from affecting its contents. The packing machines place the bags into boxes for storage or distribution.

Microwave Bag

The microwave popcorn bag was first introduced in 1971. The package consists of four layers stacked on top of each other in the following order: 1) a "top" sheet of paper 2) a gray square 3) a metalized polyester film and 4) a "bottom" sheets of paper. The metal is safe to use in a microwave because the layer is so thin. Instead of reflecting microwave energy, the thin metal layer absorbs the microwave energy and transfers the produced heat to the kernels. When the temperature reaches 400°F, the kernels start to pop. [6]

Video: Explanation regarding microwave popcorn bags

Preservation and Dehydration

Microbial Growth

Preservation is necessary for a variety of foods, especially popcorn. The high moisture levels upon harvesting will inhibit full expansion of popcorn kernels and also render them susceptible to microbial growth and spoilage. Microorganisms such as Listeria monocytogenes (which causes the foodborne disease Listeriosis) may prosper and survive at greater rates in high-moisture environments.[7]

Dehydration

To prevent spoilage to this perishable grain, harvesters dry the popcorn to reduce its moisture content to 14%. This ensures that optimal popping and storage conditions are attained. One method of drying involves storing ears of corn in specialized structures to be naturally air-dried. This process is very slow and can take up to 8-12 months for completion.[8] Another method involves storing the ears of corn in large silos and pumping hot air inside to rapidly dry the popcorn. The temperature of the air usually ranges from 90°F-100°F, with the maximum being 120°F before over-drying occurs.[9] Over-drying of the kernels may prevent them from popping when cooked. Air velocity and humidity of the air may also be increased in the silos to accelerate the drying process and ensure all ears of corn reach the desired moisture level. It is relatively fast to remove the moisture in kernels while maintaining the quality of the food due to its small size and low surface area.[9] After dehydration has occurred, the kernels become slightly hygroscopic, which means they will readily absorb moisture, given the opportunity.

Chemical and Physical Properties

The pericarp, or outer hull of the popcorn, has a crystalline structure which is composed partly of cellulose. Under normal conditions, the pericarp is thick and impermeable to any moisture, which is hidden under the pericarp in the starchy endosperm. With the application of heat, pressure builds up in the interior of the pericarp. The pressure eventually builds up to the point where the endosperm bursts into an airy foam.[10]

Carbohydrates

Popcorn mostly consists of carbohydrates: 1-cup serving of air-popped popcorn has 6.23 g of total carbohydrates. Specifically, a 1-cup serving of popcorn contains 4.96 g of dietary starch, 1.2 g of dietary fibre, and 0.07g of sugar.[10]

Starch

Starch is a polysaccharide that exists in the form of starch granules in popcorn. Starch molecules, known as amylose, are packed within these starch granules. Polysaccharides are insoluble in water, tasteless with a sweetness index of 70-80, and digestible only after they have been heated and broken down.[10]

Sucrose

Sucrose is a disaccharide composed of linked monosaccharides: glucose and fructose. Popcorn is considered a high-GI food, with a Glycemic Index of 72. This means that popcorn can cause the blood sugar level to rise quickly after consumption.[11]

Dietary Fibre

Insoluble and soluble fibre are found in the cell walls of plants and are indigestible in the human gastrointestinal (GI) tract. The health benefits of fibre include slowing down absorption of glucose molecules, improving digestive health, and reducing risks of certain health problems such as colon cancer and high blood pressure.[11]

Retrogradation

When unpopped kernels are left out for a period of time at room temperature and exposed to air, the moisture content drops, causing the kernels to dry out. This is problematic because kernels that are too dry cannot pop. Chemically speaking, amylose polymers orient themselves into a linear structure as shown in the figure to the right.[11] This ordered structure causes water to be squeezed out of the molecules.[11] This process is accelerated in dry environments. Fortunately, this process can be reversed by putting dry kernels into a jar with some water. After some time, moisture content will be restored.

Vitamins and Minerals

Although vitamins and minerals are only needed in small quantities, they have a huge impact on proper health functions.

Vitamins are organic compounds that are classified as either water soluble (Vitamin C, thiamin, riboflavin, niacin, pyridoxine, vitamin B12, and folate) or fat soluble (Vitamin A, D, E, and K).[11] It is important to note that vitamins do not contribute to the physical characteristics of food. Popcorn contains small amounts of Vitamin A and only trace amounts of Vitamin K. Vitamins found in larger quantities are B vitamins, including, thiamine, riboflavin, Vitamin B6 and niacin.[11] These vitamins help give the body energy to perform daily activities.

Minerals are inorganic molecules that act as co-factors and participate in chemical and biochemical reactions. Popcorn contains trace amounts of iron, calcium, phosphorus, magnesium, and potassium.

Aroma Constituents

Reactions between olfactory regions of our nasal passages and inhaled volatile constituents take place, creating an aroma for individuals to either enjoy or detest.[12] Several different chemical compounds listed below are intermixed in popcorn, creating a strong and flavourful aroma:

- Pyrazines - Responsible for nutty aroma that is specific to popcorn due to the acetyl pyrazine derivative. Pyrazines arise from non-enzymatic browning reactions.[12]

- Furans - Possibly arise from carbohydrate material contained in kernels as a result of heat. Maillard browning pathways allow for furan derivatives to form, contributing to popcorn flavour. 5-methyl furfural is the cause of the smooth aroma of popcorn.[12]

- Pyrroles - The extent of the contribution of unidentified derivatives to popcorn flavour from pyrroles is unclear. Derivatives have been isolated from model sugar-amino acid browning systems.[12]

- Aldehydes - May be partially responsible for the eventual onset of the stale flavour of popcorn.[12]

- Phenols - The “clove”-like aroma is brought upon by 4-vinyl-2-methoxyphenol. 4-vinyl-phenol possesses an unpleasant smoky aroma.[12]

- Vanillin - Also contributes to the flavour and aroma.[12]

Sensory Properties

Appearance Factors

Yellow kernels are desirable for manufacturers. After generations of selective breeding, white kernels are being pushed aside while yellow kernels are increasing in number. The yellow kernels produce two specific hybrids: "mushroom" and "butterfly" shaped products.[3] Popped butterfly corn is irregular in shape, with protruding "wings", as seen in movie theatre popcorn. Mushroom popcorn is ball-shaped. Most ready-to-eat popcorn products are of the mushroom variety because of their less fragile nature. Both types are shown in the figure to the right. [3]

Textual Factors

Starch, which makes up corn, is a sol: solid proteins and plant polysaccharides dispersed in a liquid continuous phase of water. This colloidal dispersion allows the tight packing and hard texture of unpopped kernels and the fluffy texture of popped corn.[3] During the cooking process, the continuous water phase boils and leads to the rapid explosion of the kernel as the proteins and polysaccharides align. This alignment turns the kernel inside-out, making a "pop" sound and allowing the kernel to expand 44.5x its original volume. The sol lends to the good mouth-feel of the cooked product.[3]

It's also necessary for the corn to be of the proper breed to produce a light and fluffy mass upon popping, instead of a dense mass that could be found with other breeds. As stated previously, mushroom and butterfly popcorn are the breeds most desired by consumers.[3]

Flavour Factors

The main polysaccharide in corn, like most other plants, is starch. Starch is broken down a bit in the mouth by the enzyme called salivary amylase, a component of saliva, into maltose. Maltose is slightly sweet - 20 on the Sweetness Index, compared to 100 for sucrose -and will lead to a sweeter but still bitter flavour of popcorn.[11]

Many microwave popcorns also have margarine, butter, or butter flavouring added to them. They are examples of solid emulsions of a dispersed phase of water in a oil/fat continuous phase. These ingredients enhance and add to the flavour of the popcorn.[11]

Regulations

Labelling

Based on the Consumer Packaging and Labelling Act and Regulations, seven different components are required on packaged popcorn. These include the common name, the net quantity, name and address, list of ingredients, nutrition facts table, expiration date, and bilingual labeling.[11] In addition, two nutrient content claims are found on packaged popcorn kernels. Take for instance, Original Orville Redenbacher’s Popcorn: 1) Very high source of fibre: There is 7g of fiber per serving.[13] 2) No artificial colours and flavours.[13]

Indiana-Canada Bilateral Trading Relationship

Canada and Indiana (USA) depend on each other for popcorn kernel sales. Canada supplies corn seeds to support Indiana’s corn crop, and in return, Indiana supplies popcorn kernels, including microwave popcorn, to Canadian supermarkets.[14] This mutual trade benefits both countries: more jobs are created in Indiana farms while an economic profit is gained in the marketplace in Canada. In 2011, $20 million in corn seed was exported to Indiana from Canada and $11 million worth of microwave popcorn was imported into Canada from Indiana.[14] It is important to note that before entering Canada, popcorn kernels must meet certain requirements from the Canadian Food Inspection Agency. More specifically, companies that own the farms in Indiana must be licensed with the Canadian Food Inspection Agency. In addition, the kernels need to meet all the health and safety requirements of the Food And Drug Regulations.[11]

Trends

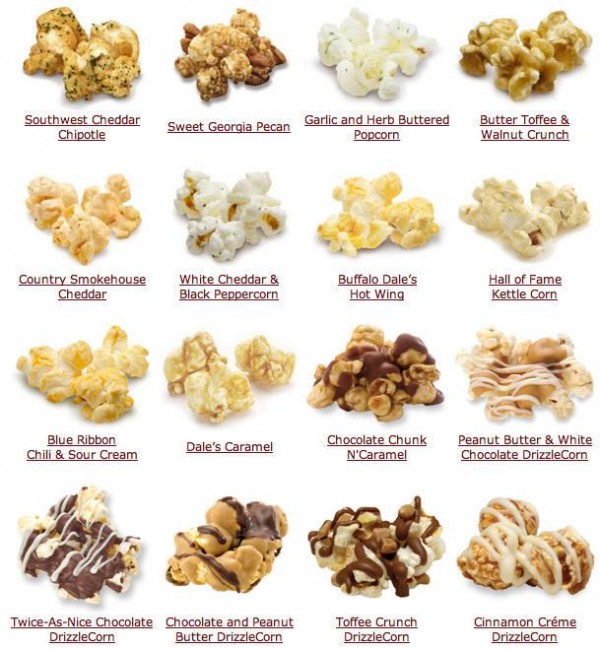

Since 2000, popcorn sales have been gradually increasing. For instance, manufacturers have noticed a 42% increase in consumption of ready-to-eat popcorn within the last five years[15]. Thus, companies have been moving towards making ready-to-eat popcorn (i.e. Kettle Corn). However, microwave popcorn is still being manufactured due to its high popularity. As shown on the graph below, popcorn is not consumed as much as other snack foods in Canada. Between 2004 and 2009, the popcorn market in Canada increased at a compound annual growth rate of 7.8%. In 2009, 92.4% of the popcorn market consisted of microwave popcorn. The biggest popcorn market in Canada is ConAgra Foods, Inc. which owns Orville Redenbacher’s. ConAgra Foods, Inc. is currently based in Mississauga, Ontario.[16]

Benefits and Risks of Microwave Popcorn

Benefits

Microwave popcorn is a convenient snack, packaging is easy to use, and the popcorn itself is cheap, fresh and delicious. In terms of nutrition, microwave popcorn is high in antioxidant (polyphenols) and dietary fibre. According to the report of National Meeting & Exposition of the American Chemical Society (ACS), popcorn's polyphenol concentration is higher than many fruits and vegetables. [17] Microwave popcorn can be stated as fat and sodium free when no butter or salt are added.

Risks

It is hard to predict the time needed to cook the popcorn kernels in the microwave, since different microwave ovens have different powers: when added in the microwave for too long, the kernels start to burn, resulting in a bitter taste. When taken out of microwave too early, popcorn kernels are left unpopped, resulting in waste. A good way to determine when a bag of popcorn is finished popping is to wait until there is a pop every 1-2 seconds.[3] Though this requires active monitoring of the cooking process, and thus making it less convenient, it will ensure that most of the kernels are popped without being burned.

There is a possibility of hazardous substances in microwave popcorn:

- Diacetyl, used as an artificial butter flavor, is hazardous to consumers when inhaled consistently, causing scarring in the lungs. Generally, diacetyl fumes are produced during kernel popping. Minor symptoms include having difficulty exhaling; however, continuous exposure to diacetyl may lead to death. Fortunately, this situation is extremely rare. [18]

- 2,3-pentanedione (PD), another artificial buttery flavour and aroma, can damage the lungs and alter gene expression in human brains, according to research in The American Journal of Pathology. [19]

- Perfluorooctanoic acid (PFOA, also known as C8) is used in the coating of microwave popcorn bags as a grease-proofing agent. During heating, PFOA can seep into the popcorn. It is identified as a possible carcinogen by U.S. Environmental Protection Agency (EPA) in 2005 because of its blood clotting abilities as well as its cancerous symptoms. As a result, eight U.S. companies agreed to remove PFOA from their products by 2015. [19]

- Trans fat in partially hydrogenated oils has been proven to increase the risk of heart disease by raising LDL cholesterol and lowering HDL cholesterol. Approximately 3000 Canadians die from heart disease caused by high consumption of trans fat every year. [18]

- Sucralose, used as an artificial sweetener, is not metabolized in human bodies. It may cause digestive side effects by compromising the good bacteria in the gut, which help with normal gut function by boosting the immune system, synthesizing vitamins, and fighting against bad bacteria. High consumption of sucralose can cause DNA damage to the colon, potentially leading to digestive problems.[20] Other symptoms, such as headache, stomach ache, and allergies, have been reported by consumers.[21]

Health Issues Related to Microwave Popcorn

Recently, there have been some concerns over the health of workers at most microwave popcorn plants, as they claimed to have acquired a lung disease called bronchiolitis obliterancs, also known as “Popcorn Packers Lung” while working at the company.[22] The disease is characterized by skin irritation on the hands and feet and difficulty breathing due to irreversible narrowing and obstruction of the small airways, resulting in chronic coughing and shortness of breath.[22] A test result from an animal study confirms that the disease is likely due to exposure to vapours from diacetyl, a chemical used to impart the butter-like flavour, and exposure to vapours from the intact butter flavouring mixture itself. [23] Workers who have contracted the disease may require lung transplant to maintain life. However, federal health officials state that the amount of popcorn butter flavouring consumers inhale in making or eating popcorn is believed to be too low to pose a health risk.[22]

Interesting Facts

- Popcorn can pop up to 3 feet in the air. That is almost a meter high!

- Popcorn is a type of corn, which is a member of the grass family.

- Air-popped popcorn is a low calorie food with only 31 calories per cup. With oil, it has 55 calories per cup.

- Popcorn sales are highest in the fall.

- Popcorn needs 13.5-14% moisture to pop into a fluffy ball.

- Almost every microwave has a "popcorn" button because Canadians pop so much popcorn!

- If you made a trail of popcorn from New York City to Los Angeles, you would need more than 352,028,160 popped kernels.

- Nearly all Act II, Newman's Own, Orville Redenbacher's, and Smart Balance microwave popcorns have replaced partially hydrogenated oils with (mostly) palm oil.

- Pop Weaver has switched to using canola oil, and it is the only brand of microwave popcorn that is made with canola oil.

- 40% of American women prefer the aroma of freshly popped popcorn to the smell of the cologne their husbands or boyfriends wear, and 25% prefer popcorn's smell to the smell of a bouquet of flowers. This percentage increases as women get older. 35% of American men prefer the aroma of freshly popped popcorn to the smell of the perfume worn by their wives/girlfriends.

- 43% of Americans eat microwave popcorn while watching home videos. In fact, 25% say just smelling microwave popcorn compels them to watch a video.

More facts can be found at www.popcorn.org

Team 01 Video

Interview With Popcorn

About: Popcorn is nervous about her job interview but moves past her fears. She talks about her past in the corn field and how her popularity has been increasing in Canadian households. Watch the video to learn more about Popcorn's story!

Summary

Team 01 Reflection

Team 01 has gained much insight to the topic of microwave popcorn: having little knowledge at the beginning of the term made us curious about the facts regarding microwave popcorn. After weighing the pros and cons of microwave popcorn processing, team 01 has determined that microwave popcorn is safe to consume: popcorn is nutritionally beneficial with a high fiber and micronutrient content. Moreover, eating popcorn in moderation can decrease risks of certain diet-related diseases. Much research has been done with short term effects of consuming microwave popcorn, but long term effects have not been determined thus far.

Summary

In the last three decades, popcorn has become a widely popular snack in North America, with 17.3 billion quarts of popped popcorn being consumed each year. Many popcorn flavours and varieties have derived from this popularity. This includes flavours consisting of caramel, strawberry, and butter, to name a few. These have found a place in movie theatres, amusement parks, stadiums, and supermarkets. An expanded availability of popcorn products has given consumers an array of options to choose from. In response to the expansion, some customers have become critical consumers and have questioned the health risks and benefits of popcorn, as well as the product’s origin and processing. Specifically, some complain about genetically modified corn. However, not enough research has been done to prove the risks associated with GMO on human health. The popcorn industry will continue to expand throughout North America and will stay as Canada's favorite snack for years to come.

Potential Exam Question

QUESTION: You want to eat popcorn but the only kernels you find in your cupboard are two-year-old popcorn kernels. Since they do not seem to be spoiled, you place them into a paper bag and then into the microwave. After two minutes, you look into the microwave but most of the kernels have not popped. What is the reason for the unpopped kernels? What could you have done to prevent this?

ANSWER: Under normal conditions, with the application of heat, pressure builds up in the interior of the kernels. The pressure eventually builds up to the point where the endosperm bursts into an airy foam. When unpopped kernels are left out for a period of time at room temperature and exposed to air, the moisture content drops, causing the kernels to dry out. This phenomena is known as retrogradation. This is problematic because kernels that are too dry cannot pop. Fortunately, this process can be reversed by adding dry kernels into a jar along with some water. After some time, moisture content should be restored.

References

- ↑ 1.0 1.1 The Nibble. Popcorn History: The History Popcorn in the U.S. (2012). Accessed March 17 2013 from http://www.thenibble.com/reviews/main/snacks/popcorn-history.asp

- ↑ Oxford English Dictionary, online edition (2012). Accessed March 7, 2013 from http://www.oed.com/?authRejection=true&url=%2Fview%2FEntry%2F112600

- ↑ 3.0 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 Popcorn. Wikipedia (2013). Accessed March 18 2013 from http://en.wikipedia.org/wiki/Popcorn#cite_ref-Hallauer_214_16-1

- ↑ 4.0 4.1 4.2 4.3 4.4 4.5 4.6 4.7 The Popcorn Board Web Site. The Popcorn Board (2013).Chicago, Illinois. Accessed 21 February from http://www1.agric.gov.ab.ca/$department/deptdocs.nsf/ba3468a2a8681f69872569d60073fde1/b5b5c4cd7a09c59887257914006014f4/Information/0.7150!OpenElement&FieldElemFormat=jpg 2013.

- ↑ 5.00 5.01 5.02 5.03 5.04 5.05 5.06 5.07 5.08 5.09 HowStuffWorks Show: Episode 1: Popcorn (2011). Youtube. Accessed March 16 2013 from http://www.youtube.com/watch?v=q2lKV02JzPc

- ↑ The Microwave Popcorn Bag: Not just A Pretty Package (2012). Acswebinars. Accessed March 20 2013 from https://www.youtube.com/watch?v=NtwkzXi6ylc&feature=player_embedded

- ↑ Listeria monocytogenes (2013). Wikipedia. Accessed March 20 2013 from http://en.wikipedia.org/wiki/Listeria_monocytogenes

- ↑ P.R. Carter, D.R. Hicks, J.D. Doll, E.E. Schulte, R. Schuler, and B. Holmes. Popcorn (1989). Accessed March 20 2013 from http://www.hort.purdue.edu/newcrop/afcm/popcorn.html

- ↑ 9.0 9.1 Popcorn: From Seed to Snack (2013). Accessed March 20 2013 from http://www.popcorn.org/ForTeachers/TeachingGuide/FromSeedtoSnack/tabid/87/Default.aspx

- ↑ 10.0 10.1 10.2 Bruso, J. Is Popcorn High in Carbohydrates? (2012). San Francisco Chronicles. Accessed March 18 2013 from http://healthyeating.sfgate.com/popcorn-high-carbohydrates-3882.html

- ↑ 11.00 11.01 11.02 11.03 11.04 11.05 11.06 11.07 11.08 11.09 UBC. Food Standards, Regulations and Guides - Food Additives (2012). Accessed March 14 2013 fromhttp://wiki.ubc.ca/Course:FNH200/Lesson_04

- ↑ 12.0 12.1 12.2 12.3 12.4 12.5 12.6 Bruso, J. Is Popcorn High in Carbohydrates? (2011). Accessed March 20 2013 from http://ir.library.oregonstate.edu/xmlui/bitstream/handle/1957/26817/WALRADTJOHN1969.pdf?sequence=1

- ↑ 13.0 13.1 Orville Redenbacker's. Family Favorites: Butter Microwave Popcorn (2013). Accessed March 04 2013 from http://www.orville.com/homemade-popcorn

- ↑ 14.0 14.1 United States Trade Advocacy. Agri-Food Trade Policy: Indiana- Canada (2012). Accessed March 04 2013 from http://www.agr.gc.ca/itpd-dpci/amr/4820-eng.htm

- ↑ Conagra Foods, Inc. Orville Redenbacher pops into the snack aisle with four new ready to eat gourmet flavours (2012). Accessed March 1 2013 from http://www.newswire.ca/en/story/999605/orville-redenbacher-pops-into-the-snack-aisle-with-four-new-ready-to-eat-gourmet-flavours

- ↑ Reporter Linker. Popcorn Industry Overview in Canada to 2014 (2011). Accessed March 1 2013 from http://www.reportlinker.com/p0564096-summary/Popcorn-Market-in-Canada-to-Savory-Snacks.html#sthash.r1f8MjGI.dpuf

- ↑ http://www.care2.com/greenliving/popcorn-may-be-the-perfect-snack-food-say-researchers.html#ixzz2O3a0ZW7D

- ↑ 18.0 18.1 Silverman, Jacob. Is microwave popcorn toxic? (2012). Accessed March 20 2013 from http://health.howstuffworks.com/diseases-conditions/respiratory/popcorn-lung.htm

- ↑ 19.0 19.1 Hubbs AF, Cumpston AM, Goldsmith WT, Battelli LA, Kashon ML, Jackson MC, Frazer DG, Fedan JS, Goravanahally MP, Castranova V, Kreiss K, Willard PA, Friend S, Schwegler-Berry D, Fluharty KL, Sriram K. Respiratory and olfactory cytotoxicity of inhaled 2,3-pentanedione in Sprague-Dawley rats. 2012. Accessed March 20 2013 from http://www.ncbi.nlm.nih.gov/pubmed/22894831

- ↑ Johnson, A. DOES SUCRALOSE HAVE DIGESTIVE SIDE EFFECTS? 2010. Accessed March 20 2013 from http://www.livestrong.com/article/333994-does-sucralose-have-digestive-side-effects/#ixzz2OaThU4Un

- ↑ Klein, D. Microwave Popcorn Danger. 2012. Accessed March 20 2013 from http://www.organicliaison.com/blog/tag/microwave-popcorn-danger/

- ↑ 22.0 22.1 22.2 http://search.proquest.com.ezproxy.library.ubc.ca/docview/200315508?accountid=14656

- ↑ More than you ever wanted to know about popcorn. (1999). Food Management, 34(6), 96-96. Retrieved from http://search.proquest.com.ezproxy.library.ubc.ca/docview/215884116?accountid=14656