Course:FNH200/2011w Team07 Chocolate

Chocolate Tempering

Introduction

What is Tempering

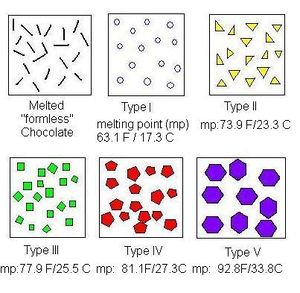

Tempering refers to a process of heating and cooling chocolate to prepare it for the production of quality chocolate products, as well as for moulding, dipping and enrobing. Tempering is the final step in chocolate processing. The heating and cooling is carried out at specific temperatures, along with specific amounts of mixing, in order to achieve the highest quality product. Once heated, melted and then cooled, the solid fats in cocoa butter can crystallize into six different structures, type I-type VI, each having its own distinct characteristics.

The desire in tempering is to produce a product in which there are as many type V crystal structures as possible, thus creating a higher quality chocolate product than tempered chocolate with fewer type V crystals. Proper tempering results in chocolate with qualities such as: contraction, ideal for mould release, smooth texture, glossy shine, resistance to fat bloom, snaps when broken rather than crumbling and lasts for extended periods of time under proper storage conditions.

History

Using tempering as a proper technique in making chocolate can be traced back to over 160 years ago. By looking through the history of chocolate, chocolate tempering had been utilized for over three millenniums to develop the various forms of chocolate we have today, taking from the watery cocoa drink the Mayans had created in 250 A.D.

Nowadays, much research and development goes into the chocolate trade, such as the fact that the British chocolate manufacturer, Cadbury, who have been making chocolate and investing in the research about the effects temperature has on chocolate crystallization.[1] They, as well as other manufacturers and scientists have been intensively researching and experimenting to obtain the condition that will allow the type V crystals to dominate the final products structure, and thus prevent the other five types of crystals from forming.

Why Do We Temper

Cocoa Butter

Cocoa butter is a processed by-product of cocoa liquor/cocoa mass, which itself is the by-product of the cacao bean. It is an edible vegetable fat, the primary solid fat in chocolate, which contributes to the continuous phase of the mixture, and also gives chocolate its unique mouth feel and stability properties. Cocoa butter is the reason why you have to temper chocolate, because it displays the polymorphism when the chocolate is heated, melted and cooled, which leads to the formation of polymorph crystals type I through type VI. The cocoa butter is composed of 3 to 4 glycerides of fatty acids; when heating and melting chocolate, the fatty acid crystals separate and then each of these different fatty acids solidify at a different cooling temperature. Therefore, the objective in tempering melted chocolate is to entice the different fatty acid crystals of cocoa butter back into one stable form.

Cocoa Butter Crystal Temperatures and Characteristics

| Crystals | Melting Temperature | Characteristics |

|---|---|---|

| I | 17°C(63°F) | Soft, crumbly, melts too easily |

| II | 21°C(70°F) | Soft, crumbly, melts too easily |

| III | 26°C(79°F) | Firm, poor snap, melts too easily |

| IV | 28°C(82°F) | Firm, good snap, melts too easily |

| V | 34°C(93°F) | Glossy, firm, best snap, melts near body temperature (37°C) |

| VI | 36°C(97°F) | Hard, takes weeks to form |

Chocolate/Fat Bloom

Avoidance of fat bloom is another main reason for tempering chocolate.[4] Chocolate bloom is described as the appearance of a moldy-looking white coating found on the chocolate's surface. This is not a real mold and doesn't affect the health or safety of consuming the chocolate, instead, it just has an obvious effect on appearance and surface texture, as well as possibly limiting the product's shelf life. Currently, two theories about fat bloom exist: Polymorphic transformation theory and phase separation theory.[5]

Phase Separation Theory:

Fat bloom is attributed to phase separation of the triglycerides within cocoa butter’s crystalline structure. This theory uses the principle that cocoa butter is a mixture of varying triglycerides, each with a unique melting temperature. The triglycerides with lower melting points will melt at higher temperatures, and eventually the liquid phase produced will occupy a greater volume than the solid. This liquid phase is pushed to the chocolate's surface through pores/fissures in the chocolate, and once at the surface these triglycerides recrystallize into the most stable form and ‘fat bloom’ has occurred.[5]

Polymorphic Transformation Theory:

Cocoa butter has 6 polymorphic forms. This theory is based around the fact that bloomed chocolates always contain polymorph VI - the most stable form. Thus, blooming occurs due to uncontrolled polymorphic transformation of cocoa butter from a less stable form, such as IV and V, to the VI form. Elevated and fluctuating temperatures appear to promote this transformation, and thus promote the rate of bloom formation. Fat blooming does not always occur when form IV/V transforms into form VI, this transition should be looked at as an aspect of recrystallization that may result in bloom.[5]

Enrobing

Enrobing is the technique of dressing a piece of chocolate (or some other substance) with an external/outer layer of liquid chocolate. The technique is enabled by tempering and results in a chocolate`s center piece being covered by an outer layer of chocolate by either pouring tempered chocolate over the center piece or dipping the center piece into tempered chocolate. The liquid coating surrounding the center piece then solidifies and encloses the inner product. Examples of this include candy/chocolate bars that have nougat, nut, caramel, or other inner filling with a chocolate outer layer, as well as fancier chocolates that may have a soft, creamy chocolate center surrounded/enrobed by a firm chocolate coating. This technique can also be used to shape/sculpt chocolate into many elaborate decorations such as geometric shapes, foliage and flowers, butterflies, and bow ties - just to name a few.

Benefits of Tempering

Tempering chocolate promotes the formation of small, consistent, stable crystals by heating and cooling at specific temperatures, which then ensures that the cocoa butter solidifies into a uniform crystal structure, enabling the chocolate to be firm/solid at room temperature. It also produces chocolate that has a smooth texture which accounts for the "melt in your mouth" feeling, a shiny or glossy sheen/appearance, a firm crispness when bitten or broken, and an even colour distribution.

Physical features of well-tempered chocolate

| Appearance | Rich in color, with a smooth, glossy surface and can be maintained for months in room temperature. “Bloom”, i.e. grayish, powdery surface, is an indication of poor quality, or chocolate that has been improperly stored. |

| Solidity | Sets hard, snaps crisply when broken, gets a lustrous sheen, feels dry to the touch and smooth in the mouth |

| Aroma | A strong chocolaty aroma - not one that's fruity or flowery - indicates good chocolate. |

| Mouthfeel | Melts at a specific temperature (1-2 degrees below normal body temperature) for a perfect mouthfeel that is creamy and smooth across the palate. The extra fine creamy texture is achieved by conching (agitation/blending) ingredients. The longer the conching, the creamier the chocolate. |

| Taste | The taste of high quality milk chocolate should be rich, sweet and chocolaty - never harsh or bitter.[6] |

Disadvantages of not Tempering

Without utilizing the methods of tempering, the melted chocolate crystals will not solidify in a completely uniform manner, resulting in an uncontrolled crystallization of the cocoa butter. This will result in crystal structures of varying size, causing the final chocolate product to be sticky and/or melt at room temperature, as well as have odd texture (lumpy/chalky/grainy) and colour (gray/dull/cloudy) characteristics. Furthermore, due to the chocolate’s poor crystalline structure, it will not have a crisp snap when breaking or biting into it.

Methods

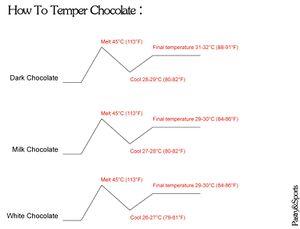

Methods for milk, dark and white chocolate are the same but the ideal tempering temperatures vary for each.

Tempering Methods:

- Slab Tempering, also known as Tabliering

- Seed Tempering

- Machine Tempering

Slab Tempering:

Chocolate is melted in a double-boiler to a temperature of 120°F/49°C for dark chocolate , 115°F/46°C for milk chocolate , and 110°F/43°C for white chocolate. Then 1/3-2/3 of this molten chocolate is moved to a cool marble slab, while the remaining 1/3-2/3 is kept at the same melting point temperature and not let to harden. The chocolate will be moved back and forth across the slab until it cools, crystallizes a little, and thickens up. The desired temperature to achieve on the marble slab is 82°F/28°C for dark chocolate, 80°F/27°C for milk chocolate, and 78°F/26°C for white chocolate. The chocolate will now be a dull, matte, paste. This chocolate, which now is partly crystalline (containing mostly unstable but also some stable crystals), is mixed back into the remaining original molten chocolate. With a clean, dry, rubber spatula, the mixture is stirred constantly until the following desired temperatures are met: Dark chocolate 90°F/32°C , milk chocolate 86°F/30°C and white chocolate should register at 82°F/28°C. During the mixing process, unstable polymorphs may melt or be transformed into stable polymorphs, producing stable crystal seeds. If needed, the bowl is warmed to slow any further thickening of the chocolate, or if the chocolate is not sufficiently tempered, a further amount may be spread on the slab briefly following the above methods. During this tedious process the chocolate must remain at the appropriate temperature to keep it in temper.[7]

| Type of Chocolate | Desired Tempering Temperature |

|---|---|

| Dark (no milk content) | 88-90°F (31-32°C) |

| Milk | 86-88°F (30-31°C) |

| White | 80-82°F (27-28°C)[7] |

Home Tempering Equipment

|

|

|

Seed Tempering:

This method follows the same temperature ranges as slab tempering. Once the untempered chocolate has melted, non-melted chocolate chunks are added in and stirred constantly. These chocolate chunks help to cool the molten chocolate and provide seed crystals as they melt. Once the desired temperature is reached, any un-melted chocolate chunks are removed, leaving only liquid chocolate as the structure that needs to cool and solidfy. This method uses the fact that beta crystals in the tempered chocolate will act as a seed to temper the newly added untempered chocolate.[8]

Home Tempering of Chocolate Using the Seed Method (2012 FNH200 Team 7 )

Machine Tempering

A chocolate tempering machine is an electronic mixing and heating pan or appliance that is designed to take all the guesswork and manual labor out of tempering chocolate. A chocolate tempering machine is an automated process that causes the molecular crystals of the chocolate to take on the Beta V form. The chocolate tempering machine does this by heating the chocolate to the precise temperature for the specific chocolate type, then cooling slightly and reheating, while mixing the chocolate in a regulated manner. These machines that are computer-controlled can keep chocolate in the tempered, melted stage for hours at a time, allowing for candies to be made without tending to the tempering process itself. When tempered chocolate cools it will be even colored, shiny, and crisp, yet will melt to a smooth, creamy consistency on the tongue.[9] Machine tempering aids in making large amounts of tempered chocolate at a time, and reduces the stress of manual tempering, where there is the worry of overheating and under mixing.

The Bakon USA Chocolate Tempering Machine

Taste

Different tastes can vary from one chocolate product to another. These taste differences are dependent on which crystalline forms are dominant during the cooling process of tempering the cocoa butter; there are six different molecular crystalline arrangements, known as polymorphs. The structure type of a particular crystalline form/polymorph is dependent on the applied temperatures and mixing rates of the cocoa butter. Furthermore, taste is can also vary greatly from one chocolate type to another (milk, white, dark) depending on the milk content, cocoa content, and sweetness level (sugar content). Many chocolates have added flavour enhancers, such as sea salt, spices, and various fruit flavours; some producers make bizarre mixtures of flavours, including but not limited to: coconut curry, ketchup and pickles, rose water and lavender, or fig, walnut, and cheese (supposedly, the chocolate bar containing fig, walnut and cheese tastes even better the longer you let it age - it's like a fine wine!).

Storage

Like all food products, where certain temperatures and humidity ranges aid in preserving and retaining the best qualities, chocolate also has its ideal storage conditions. A temperature between 15°C and 17°C is optimal to ensure that the good chocolate characteristics remain intact. If constant storage temperatures fall below this range, the chocolate may show signs of sugar bloom, and if the storage temperatures exceed 24°C the chocolate will display fat bloom. [10] If temperatures are very high, the chocolate will simply melt and deform - into chocolate sauce!

The storage site should always have a moisture content remaining below a relative humidity of 50% [10]; therefore, it is not wise to store chocolate in the refrigerator, and if you do make sure it is completely and properly sealed to keep moisture out. Other storage considerations include: keeping the chocolate stored in a dark area or wrapped in a packaging in order to prevent light penetration, and limiting the transfer of odours from external sources by keeping it away from other food products.

Others

Facts about Chocolate

- The name Theobroma cacao comes from Greek meaning “food of the Gods.”[11]

- Chocolate is poisonous to dogs and other domestic animals.[12]

- Dark chocolate contains more antioxidants than blueberries, which lowers the risk of cancer and heart diseases.[13][14]

Questions to Think about

- From type I to VI, which will form the most ideal chocolate crystals that manufactures want?

Answer:Type V crystals. - What is the optimal storage temperature for chocolates?

Answer:Between 15°C and 17°C.

References

- ↑ Bailey,J. and Bailey, L. 2011. Tempering Chocolate Forms. Retrieved March 6, 2012, from http://www.chocolates-made-easy.com/Tempering-Chocolate.html

- ↑ Beckett, S.T. 2009. Industrial Chocolate Manufacture and Use: Fourth Edition. Blackwell Publishing Ltd, U.K., pp.262

- ↑ Chocolate. (2012, February 18). In Wikipedia, The Free Encyclopedia. Retrieved 21:38, March 6, 2012, from http://en.wikipedia.org/wiki/Chocolate#Tempering

- ↑ Nanci, J. (2008, February) Tempering - Deconstruction and Reconstruction & Illustrated Tempering. Retrieved March 6, 2012. from http://chocolatealchemy.com/illustrated-tempering/

- ↑ 5.0 5.1 5.2 Chocolate. (2012, February 18). In Wikipedia, The Free Encyclopedia. Retrieved 21:38, March 6, 2012, from http://en.wikipedia.org/w/index.php?title=Chocolate&oldid=477537101

- ↑ Phillips, S. 2000. How Chocolate Tempering Works. Retrieved March 8, 2012 From http://baking911.com/learn/ingredients/chocolate/melt-or-temper/how-chocolate-tempering-works

- ↑ 7.0 7.1 Steve Leffer, Chocoholic & Chief Taster.About Tempering. Retrieved March 5, 2012, from http://www.chocoley.com/abouttempering.htm

- ↑ CARGILL. 2011. Tempering Chocolate: Hand Tempering Methods. Retrieved March 4, 2012, from http://www.wilburchocolate.com/wcm/groups/internal/documents/document/na3041991.pdf

- ↑ All Chocolate Tempering. 2010. What is a Chocolate Tempering Machine?. Retrieved March 5, 2012, from http://www.allchocolatetempering.com/chocolate-tempering-machine/

- ↑ 10.0 10.1 Chocolate. (2012, February 18). In Wikipedia, The Free Encyclopedia. Retrieved 21:38, March 6, 2012, from http://en.wikipedia.org/wiki/Chocolate#Storage

- ↑ Gibson, A.C. Cacao, Food of the Gods. Retrieved March 20, 2012, from http://www.botgard.ucla.edu/html/botanytextbooks/economicbotany/Theobroma/index.html

- ↑ Helmenstine, A.M. 2012. Theobromine Chemistry: Theobromine is Chocolate’s Caffeine Relative. Retrieved March 20, 2012, from http://chemistry.about.com/od/factsstructures/a/theobromine-chemistry.htm

- ↑ Parnes, R.B. Antioxidants: What You Need to Know. Retrieved March 22, 2012, from http://health.howstuffworks.com/wellness/food-nutrition/facts/antioxidant4.htm

- ↑ Bhagwat, S., Haytowitz, D.B., and Holden, J.M. USDA Database for the Oxygen Radical Absorbance Capacity (ORAC) of selected Foods. Retrieved March 20, 2012, from http://www.ars.usda.gov/SP2UserFiles/Place/12354500/Articles/AICR07_ORAC.pdf