Course:FNH200/2011w Team03 Sourdough

Introduction

Imagine yourself walking into your local bakery looking for a loaf of bread to serve to your guests later that evening. Have you ever picked up a loaf of sourdough bread and wondered what characteristics to look for to make it a "good loaf" of bread? Or have you ever wondered how symbiotic microorganisms work together to give sourdough such a distinctive sour taste? Maybe you actually wanted to make a loaf of homemade sourdough yourself and just never knew how. Here is a little introduction of what sourdough bread is.

Sourdough bread is a form of naturally leavened bread that has been produced by man for thousands of years.[1]. In its simplest form sourdough consists only of flour, water, and naturally occurring yeast and bacteria. When the flour and water are mixed, the omnipresent yeast and bacteria from the natural environment are incorporated into the dough. When left for several days to ferment, the dough will become bubbly and sour. The sour properties of the bread are derived from the metabolic activity of Lactobacillus bacteria, which feed on the dough, producing acetic and lactic acids as by-products, and ultimately help to preserve the bread. [2] Sourdough starter culture can be preserved indefinitely if maintained properly and stored in the right conditions. [2]The leavening is due to carbon dioxide released when yeasts feed on the dough. The carbon dioxide then rises through the bread, producing air pockets and giving the bread a light texture. [3] Sourdough bread differs in many ways from its modern counterparts, which are made from commercially isolated yeasts and do not require fermentation.

History

Any historical discussion of bread must start by making the distinction between leavened and flat breads. Flat breads, like pita or tortilla, are mixtures of flour and water, which are baked soon after mixing. Leavened breads on the other hand, are allowed to grow and rise before being baked, giving them a lighter texture. This phenomenon is due to the action of yeast.[4]

Sourdough bread is believed to be the earliest form of leavened bread. Historians have found evidence of its production in Ancient Egypt as far back as 1500 BC. While impossible to prove, it is highly probable that the leavening properties of sourdough were discovered by accident. When bread dough is left to sit in a warm place for several days, it grows in size and develops a sour taste; thus, the first loaves of leavened sourdough were quite possibly due to an ancient baker forgetting about his dough. While today we understand this to be due to the presence of yeast (which cause the growth) and bacteria (which give the sour taste), throughout the majority of bread-making history the reasons for why dough would change with time were unknown.

Sourdough remained the most common form of leavening throughout Europe until the Middle Ages when bakers realized that barm—a scummy, yeast-containing byproduct of beer making—also produced a leavening effect on their breads.[5]. It was not until the late 19th century that a process had been developed to isolate yeast. [6], thus bringing in the modern era of bread production.

Chemical Interactions

When examining the physical properties and taste of sourdough, the most obvious features would most likely be the unique sour taste as well as the large air pockets located within the bread. In fact, these distinctive characteristics of sourdough are largely attributed to chemical byproducts from a sourdough starter culture, which consist of flour, water, yeast, and lactic acid bacteria (LAB).[7] Therefore, the chemical reactions relating to sourdough production need to be considered in order to understand why sourdough displays such unusual qualities.

The Symbiotic Nature of the Starter Culture

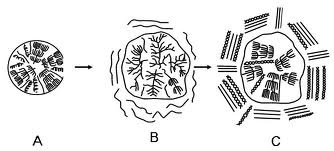

First generation sourdough starter is the initial mix of flour that naturally contains an assortment of yeast and bacteria, and will spontaneously ferment with the addition of water. [3] The species that predominate in most sourdough starters are yeast, often of the genus Saccaromyces cerrivasae, and lactic- acid fermenting bacteria or Lactobacillus (LAB). [8]The microorganisms in the culture have an important symbiotic relationship, and their synergistic fermentation of sugar leads to the production of flavouring compounds that provide the distinctive texture, complex flavor and increased shelf life to the bread. [2]. In order for both organisms to reproduce and remain viable, they need to be able to generate energy only from the starch molecules inside the flour, since there are very low amounts of oxygen available to undergo aerobic respiration. [9]. However, yeast and LAB are lower order organisms, thus they need to break down the starch into simpler sugar compounds before anaerobic respiration (fermentation) can begin. When flour is immersed in water, its water activity is raised allowing the enzymatic activity of amylase in the wheat to break down starch into maltose, a disaccharide, which in turn is converted to glucose a monosaccharide through the action of maltase. Glucose can be fermented by yeast. [10] Yeast break down the glucose formed through the enzymatic activity of flour in water and produce ethanol, an alcohol, and carbon dioxide. [10] The amount of fermentable carbohydrate in the flour varies with the type of cereal, and depends on the extent of starch hydrolysis, and the activities of microbial enzymes and contaminants. [11]. The presence of water in flour causes starch molecules to swell due to the process of gelatinization. [7] In turn, the swelling will enable a higher amount of amylases to contact the amylase/amylopectin molecules, allowing for more efficient starch degradation. [7] Thus, more glucose molecules will be available for catabolic processes during alcohol fermentation. After the starch has been degraded, the yeast can then ferment the glucose into carbon dioxide and alcohol, thereby making energy to support its own cellular processes. [9]. This pathway of alcohol fermentation is shown in the diagram below to the right as the EMP pathway. Yeast can only utilize glucose and strictly follow the EMP pathway. [9]. Once the flour is baked, the carbon dioxide molecules inside the flour will facilitate leavening of the bread and also solidify, forming solid air pockets in sourdough, which is the reason why bread is a solid foam product. [7]

Fermentative Pathways

There are two fermentative pathways that LAB can undergo to produce energy for itself and also the acidic byproducts that contribute to the sour taste in sourdough. The two pathways are shown to the right as either the EMP pathway or the Heterofermentative pathway. The pathway undertaken will depend on the structure of the sugar compounds available for use as a substrate, and also the properties of the bacteria. The most common genus of LAB incorporated into sourdough is Lactobacillus, and the fermentative pathways that Lactobacillus will undergo will depend if they are homofermentative, heterofermentative, or facultatively fermentative. Homofermentative Lactobacilli will only produce lactic acid as an end product by means of the EMP pathway, starting with glucose as the substrate.[12]. Therefore, similarly to yeast, lactobacilli will produce pyruvate as an intermediate, except that the pyruvate will then be converted into lactic acid and not ethanol. [12]. Since lactic acid has a pH of 3.86, this high level of acidity will create a sour flavour in the bread. [12]. Heterofermentative lactobacilli will only follow the heterofermentative pathway shown below. However, during the breakdown of glucose, acetyl-phosphate can be produced and converted into acetic acid, yielding a second product of high acidity (pH 4.8) that is not formed from the EMP pathway. [9]. A prevalent strain of heterofermentative lactobacilli in sourdough is Lactobacillus sanfranciscensis. [9]. Lactobacillus sanfranciscensis contains enzymes that enable it to breakdown maltose in starch into a molecule of glucose and glucose 6 phosphate. Glucose 6 phosphate will directly enter the heterofermentative pathway, forming a combination of mixed end products such as lactic acid, ethanol, carbon dioxide, and acetic acid. [9]. The remaining glucose molecule will be secreted out of the lactobacillus and into the external environment. The ability of Lactobacillus sanfranciscensis to use maltose as a substrate is advantageous because it would remove glucose competition between yeast. [9]. Facultatively heterofermenantive lactobacilli are able to undergo both the EMP pathway and the heterofermentative pathway depending on the sugar compounds that are available. If glucose is present, then they prefer to use only the EMP pathway and produce lactic acid. However, if glucose concentrations are low, then the lactobacilli will scavenge for pentoses (5 carbon sugars) and incorporate them into the heterofermentative pathway. [9]. The pentoses will usually be converted into acetic acid as the end product.[9]. When lactic acid and acetic acid are combined together, a very unique sour taste will be generated leading to the successful production of sourdough.

![[13]](http://wiki.ubc.ca/images/thumb/d/dc/Metabolic_Pathways.jpg/644px-Metabolic_Pathways.jpg)

Preparation

Sourdough Starter

Due to the difficultly of creating a proper starter culture, a reliable method was developed by Debra Wink by systematically testing the acidity and temperature conditions needed to promote the growth of the desirable microorganisms. The following starter culture and recipe are derived from this [14].The three important factors to reach these optimum conditions are:

- Use whole grain flour

- Acidify the flour medium

- Maintain temperature at approximately 75F

Whole rye or wheat flour is recommended because the desired yeasts normally inhabit the cereal hulls which are discarded to make refined flour. The required degree of acidification of the starter is provided by using apple cider or unsweetened pineapple juice instead of water to get the culture started. The warm room temperature speeds up the process. The direct instructions are:

- On the first day, mix 2 tbsp whole grain flour and 2 tbsp unsweetened pineapple juice

- On the second day, add 2 tbsp whole grain flour and 2 Tbsp unsweetened pineapple juice

- On the third day, add 2 Tbsp whole grain flour and 2 Tbsp unsweetened pineapple juice

- On the fourth day, keep 1/4 cup (2 oz.) of starter after stirring down. Discard the rest.

By the fourth day, the starter culture should exhibit signs characteristic of yeast (bubbling, expanding, smell of yeast). From this day on it is necessary to discard some starter to keep the proportion of fresh flour high enough to support the growth of the yeast while keeping the total volume of starter manageable. Feed the starter once per week with :

- 1 oz. bread flour (1/4cup)

- 2 tbsp spring water

Once you have the starter keep it loosely covered in the refrigerator and feed it once per week with the above mentioned amount of floor and water. For the two days prior to making the bread refeed the starter.

Bread Recipe

The ingredients for the bread now that you have your starter culture are[14]:

- 1 cup whole wheat flour

- 2 ½ cups white bread flour

- 1 ½ tsp salt

- 1 ½ cups spring water

- ¼ cup starter

Mix the dry ingredients in a large bowl and then dissolve the starter in water (use non-chlorinated water because choline will kill gas-generating yeast and bacteria). Pour the water on the flour while stirring the mixture. Then shape the dough into a ball and cover the bowl with plastic. If the starter is very fluid, ¼ cup of additional flour should be added to maintain a moist and firm consistency. The water level in the dough affects the porosity of the bread. Wet dough produces breads with big holes.

Fermentation:

Leave the covered bowl at room temperature (24C) for approximately 18 hours. During this time the dough should double in size.

Folding and resting:

Sprinkle some flour on a large cutting board and empty the dough from the bowl onto the board. Spread the dough gently sot that it can be folded in thirds and then folded once more to form a ball. Cover it with plastic again and let it rest for 15 minute.

Proofing:

Use a towel to line the large bowl and sprinke wheat bran or oat bran on the towel to keep the dough from adhering to the towel. Transfer the dough to the lined bowl and cover the bowl or with another moistened towel. Leave the dough to rise for 1 ½ to 2 hours.

Baking:

To obtain a crispy crust to the sourdough bread bake the loaf in a hot oven with plenty of moisture during the baking period. This can be done by baking the dough in an enclosed space such as a clay baking clouch or by spraying some water on the dough when it is placed in the hot oven and keep a shallow pan with water underneath it to create a hot steam.

Thirty minutes before baking, preheat the oven to 475F. When the oven is ready, work quickly to open the oven and sprinkle some bran in the bottom of the heated Dutch oven to keep the bread from burning and sticking. Make some decorative 1 cm deep slashes with a knife for stylistic purposes then bake the covered dough for 30 minutes at 450F. Remove the lid from the Dutch oven and bake for another 15mins at 400F until the crust is golden brown. Then take the loaf out and let it cool for 30 minutes.

Preservation

There are many parameters that contribute to the long term maintenance of a sourdough starter culture, including the storage temperature and conditions, the consistency of the substrate or flour used and the pH of the dough which directly correlates to the specific microorganisms present in the starter culture.

pH

The ratio of lactic acid to acetic acid is important for the final flavour. [16] Ideally, more acetic acid is produced than lactic acid as acetic acid improves quality in leavened dough, and one way to increase its ratio is by lowering the water activity of the starter. [17] The heterofermentative LAB will produce a mixture of lactic acid and acetic acid, however the homofermentative LAB only produce lactic acid. [10]. For optimal activities and maintenance, the ratio of LAB to yeast should be 100:1. However in some starters the ratio can even reach a factor of 1000:1, in which the acidity of the bacteria can impede the normal leavening action of the yeast making it difficult for the bread to rise. Acidity can also weaken gluten resulting in a denser product. [3]The bacteria of the culture mainly serve to impart a sour flavor on the bread by lowering its pH. Usually the pH of sourdough sits between 4.0 to 4.5, and spoilage causing organisms cannot grow at a pH lower than 4.6 thus this greatly extends the storage life of the product. [10]

Water Activity

Sugars can also act as preservatives by binding excess water produced, thereby lowering water activity and subsequent enzymatic reactions along with microbial growth. [18] However, yeast are sensitive to both salt and excess sugar, which can dehydrate them by promoting too much acid to be generated by the bacteria. [19]

Temperature

Yeast and lactobacillus growth is optimal between 15 ºC and 27 ºC or room temperature. Above 35 ºC the yeast is inactivated, however at 34 ºC the bacterial activity peaks. At 21 ºC the activity of the yeast is roughly halved so the fermentation takes twice as long. Because the organisms in the starter are in a symbiotic relationship, decrease in the growth of one leads to a decrease in the growth of the other. [10]

Additional Factors

Another factor that contributes to the long-term maintenance of sourdough bread is the activity of rye amylases, which is strongly inhibited by acid in naturally fermented dough. The low pH protects starch gels until amylase is permanently denatured as bread continues to bake to higher temperatures. Additionally the sugars in the bread will undergo Maillard browning reactions when exposed to high temperatures, which imparts a rich flavour and colour to the bread. [3]

Methods of Preservation

Once the starter has begun to grow, it can be kept on the counter and maintained simply by adding flour and water on a daily basis. Alternatively, it can be stored in the refrigerator and fed once every 5 or 6 days as the cold temperature serves to slow down the activity of the yeast. The bacterial culture can be preserved by this method indefinitely. [3] The flour-water mixture can also be inoculated from a previously maintained culture, which can be 13-25% of the original starter depending on its water content. This is then mixed or kneaded and allowed to rest and leaven, which produces type 1 or traditional sourdoughs. [20] Additionally, there are two other types of sourdough bread. [10] Starter can also be purchased at the store, where on a commercial scale the starters have been preserved through freeze drying, imparting them with a greater stability and a longer shelf life than fresh starters. On a further note, because freeze drying involves sublimation directly into the gas phase, starters easily retain their shape when exposed to water. [10] Type two sourdoughs are usually of liquid form, produced in industrial tanks, permitting a precise control of the temperature. Different drying techniques along with liquid pasteurization are used to achieve microbial stability. [10] Type three sourdoughs are dry, often used industrially and produced either through spray drying or drum drying. Spray drying introduces the sourdough as small droplets are falling down in the hot air, leaving a dry particle at the end of the process. In drum drying, a thin film of product is spread over a cylinder that is heated with steam and the resulting semi-dry product on the drum is used to perform Maillard reactions so that the final product can be caramelized or toasted. [10] However, there is also loss of volatile flavour compounds during the evaporation of the water, which can be prevented by pasteurization or by cooling procedures such as the freeze drying mentioned above. An advantage for the industrial applications of sourdough starter is that it is very precise and consistent allowing for easier maintenance. [10]

Characteristics

There are 5 main differences that separate sourdough bread from other types of bread, which relate to: formula composition, external characteristics, internal characteristics, flavour and aroma, and shelf-life stability.[21]

Formula Composition

Sourdough bread uses relatively simple and basic ingredients to try to avoid various chemical and enzymatic additives found in white bread.[21]For example, white bread stales slower than sourdough bread but this is because it contains additions of surfactants and enzymes.[21] Sourdough is a more natural food, which may be advantageous since many consumers tend to choose foods with fewer additives.[21] Consumers tend to choose whole wheat bread over white bread because of the increased nutritive properties, however, sourdough bread may be another alternative since it has a mild effect on blood sugar.[22] This means that sourdough bread does not increase blood sugar, which makes it a good alternative for diabetics.[22]

External Characteristics

The outer appearance of white pan bread is usually associated with a large volume and thin crust.[21] The large volume is due to the strong flours used, high levels of fermentable sugars and the vigorous rate of fermentation of the baker's yeast. [21], around 1-2 hours.[23] The thin crust is due to dough expansion during the baking process as well as the use of surfactants in the formula.[21] Sourdough on the other hand, has lower volumes and thick and tastier crusts. [21] This is because of longer baking times and longer fermentation times,[21]such as 12-24 hours.[23] If you tap the crust with your fingertips, the bread will actually sound like it is hollow. This is how you know that you have a nicely cooked loaf of sourdough.

Internal Characteristics

The internal characteristic of sourdough bread is different from the everyday white bread as well. White bread usually uses baker's yeast and this leads to uniform crumb grains (holes) as well as thin cell walls due to its dough makeup.[21]In addition, the uniform crumbs of white bread are associated with its softness, which helps determine its freshness. [21]Sourdough bread is different because it has non-uniform crumb grains (holes) present due to its longer fermentation period of the starter.[21]These types of non-uniform holes give sourdough a more elastic but firm type of texture.

Flavour and Aroma

In white bread and sourdough bread, the odour and flavour of freshly baked bread are retained in the crust and crumbs.[21] During baking, sourdough bread has a more pungent odour because it has acids present in the volatiles contributing to smell.[21] Bread flavour is made up from various compounds produced during fermentation or baking and include products from Maillard reactions.[21] In addition, sourdough's distinct taste comes from the lactic acid produced by bacteria during fermentation.[22]

Shelf-life Stability

It is well known that breads are perishable foods and undergo changes such as "staling" (retrogradation) and microbial degradation.[21] Staling is caused by starch retrogradation, which causes the crumbs of the bread to become firm.[21] During baking, starch gelatinizes and gives bread a soft and fluffy texture.[21] After cooling, the amylose structures crystallize back into their linear form and cause the firmness associated with stale bread.[21] In addition, bread can undergo moisture loss, which leads to dry bread but this can be prevented through use of moisture-proof packaging;[21] this is why you see loafs of bread packaged in white plastic bags at the grocery store. As for microbial degradation, white bread requires the addition of antimicrobial agents to extend its shelf life.[21] Sourdough bread has a more natural way of dealing with microorganisms because it is naturally more resistant to bacterial deterioration[21]. The acid produced during fermentation helps decrease the pH of the bread and help inhibits bacterial growth.[21]

Government Regulation

In Canada, the Canadian Food Inspection Agency. [24] regulates food standards, and labeling/advertising regulations. [25] Health Canada covers Standards of identity and composition of food as well as food additives regulations. [25]. Every “food group” has different regulations and guide lines that it must abide by, in terms of additives, labeling, nutritional facts etc. Complying with this the CFIA has regulations specifically set for Grain and Baker Products (Seen in Ch. 9 of the Supplementary information on specific products Act). [24] Complying with these regulations the CFIA has set a rule that any grain and bakery product “must contain added thiamine, riboflavin, niacin, folic acid and iron at the levels prescribed by regulation. [24]. The reasons that these vitamins are added to replace [those] that are lost during processing. “On top of the previously stated required added ingredients companies can also add vitamin B6, d-pantothenic acid, magnesium and calcium may also be added to prescribed levels”. [24]. These added nutrients must be put on the nutrition facts table. When these additional vitamins are added sourdough bread companies can make the same nutrient claims as breads made using enriched flour. [24]

Export/Import of Bread/Bakery Products

Since 1988, the export of bread/bakery products from Canada to the U.S has increased from around 5% to 14%. [26] This major increase in trade is largely attributed to frozen food products, for they have a much longer shelf life compared to their unfrozen counterpart. (Due to decreased water activity (Judy Chan notes)). The trade of bread/bakery products is duty free, and has been for some time, even before the free trade agreement, FTA, was implemented. [26]

Nationwide, retail bakeries, bakeries, which sell their product “in store” such as the ones fouond in grocery stores, or private retailers generate “around $600 million” of internal revenue. [26]

References

- ↑ Dupaigne, Bernard. The History of Bread. New York: Harry N. Abrams, 1999. Print

- ↑ 2.0 2.1 2.2 Corsetti, A., Gobbetti, M., De Marco, B., Balestrieri, F., Paletti, F., Russi, L., et al. (2000). “Combined effect of sourdough lactic acid bacteria and additives on bread firmness and staling.” Journal of Agricultural and Food Chemistry 48, 3044-3051.

- ↑ 3.0 3.1 3.2 3.3 3.4 Scott, A., Wing D. The Bread Builders: Hearth Loaves and Masonry Ovens. Vermont: Chelsea Green Publishing Company, 1999.

- ↑ Cauvain, Stanley P., and Linda S. Young. Technology of Breadmaking. Berlin: Springer, 2007. Print.

- ↑ http://h2g2.com/dna/h2g2/A2791820#footnote5

- ↑ Marx, Jean & Litchfield, John H. (1989). A Revolution in biotechnology. Cambridge, UK: Cambridge University Press. p. 71

- ↑ 7.0 7.1 7.2 7.3 Chan,Judy. FNH 200.University of British Columbia. (2012). Cite error: Invalid

<ref>tag; name "Chan" defined multiple times with different content - ↑ Corsetti, A., Lavermicocca, P., Morea, M., Baruzzi, F., Tosti, N., and Gobbetti, M. “Phenotypic and molecular identification and clustering of lactic acid bacteria and yeasts from wheat.” International Journal of Food Microbiology 64 (2001): 95-104.

- ↑ 9.0 9.1 9.2 9.3 9.4 9.5 9.6 9.7 9.8 Wink, Debra. "Lactic Acid Fermentation in Sourdough." The Bread Bakers Guild of America 15 (2007): 47-51.

- ↑ 10.00 10.01 10.02 10.03 10.04 10.05 10.06 10.07 10.08 10.09 Salim-ur-Rehman, Paterson A., Piggott R. J., “ Flavour in sourdough breads: a review.” Trends in Food Science and Technology 17 (2006): 557-566.

- ↑ Martinez-Anaya. “Enzymes and bread flavour.” Journal of Agriculture and Food Chemistry 44 (1996): 2469-2480.

- ↑ 12.0 12.1 12.2 Mohn, William. Microbial Physiology. University of British Columbia. (2011).

- ↑ http://www.thefreshloaf.com/node/10375/lactic-acid-fermentation-sourdough/

- ↑ 14.0 14.1 Zamora, Antonio. "Sourdough Bread Recipe - From Scratch." How to Make Sourdough Bread. Antonio Zamora, 2012. Web. 23 Mar. 2012. <http://www.scientificpsychic.com/alpha/food/sourdough-bread.html>.

- ↑ 15.0 15.1 http://www.applepiepatispate.com/bread/sourdough-italian-french-bread/ Cite error: Invalid

<ref>tag; name "starter" defined multiple times with different content - ↑ Linko, Y., Javanainen, P., Linko, S. “Biotechnology of bread baking.” Trends in Food Science and Technology 8 (1997): 339-344.

- ↑ Vernocchi, P., Valmorri, S., Gatto, V., Torriani, S., Gianotti, A., Suzzi, G. “A survey on yeast microbiota associated with an Italian traditional sweet-leavened baked good fermentation.” Food Research International 37 (2004): 469-476.

- ↑ Gobbetti, M., Smacchi, E., Fox, P. F., Stepaniak, L., Corsetti, A. “ The sourdough microflora. Cellular localization and characterization of proteolytic enzymes in lactic acid bacteria.” Food Science and Technology 29 (1996): 561-569.

- ↑ Neysens, P., Messens, W., Vuyst, L. D. “Effect of sodium chloride on growth and bacteriocin production by Lactobacillus amylovorus DCE 471.” International Journal of Food Microbiology 88 (2003): 29-39.

- ↑ Thiele, C.; Gänzle, M. G., Vogel, R. F. "Contribution of Sourdough Lactobacilli, Yeast, and Cereal Enzymes to the Generation of Amino Acids in Dough Relevant for Bread Flavor." Cereal Chemistry 79 (2002): 45-51.

- ↑ 21.00 21.01 21.02 21.03 21.04 21.05 21.06 21.07 21.08 21.09 21.10 21.11 21.12 21.13 21.14 21.15 21.16 21.17 21.18 21.19 21.20 21.21 21.22 Kulp, Ase S. "Baker's Yeast and Sourdough Technologies in the Production of U.S. Bread Products." Ed. Julien Bogousslavsky. Long-Term Effects of Stroke. New York: Marcel Dekker, 2003.

- ↑ 22.0 22.1 22.2 Sprout, Beverly. "Why Sourdough Bread Is Healthier than Whole Wheat Bread." Helium. Helium, Inc. Web. 18 Mar. 2012. <http://www.helium.com/items/1365847-sourdough-bread-healthy-for-diabetics>.

- ↑ 23.0 23.1 Hansen, Ase S., Lisbeth Meunier-Goddik, Jytte Josephsen, Wai-Kit Nip, Peggy S. Stanfield, and Fidel Toldra, eds. "Sourdough Bread." Handbook of Food and Beverage Fermentation Technology. Ed. Y. H. Hui. New York: Marcel Dekker, 2004.

- ↑ 24.0 24.1 24.2 24.3 24.4 Canada. CFIA. Canadian Food Inspection Agency. Canadian Gov., 29 Nov. 2011. Web. 12 Mar. 2012. <http://www.inspection.gc.ca/english/fssa/labeti/guide/ch9ae.shtml>.

- ↑ 25.0 25.1 (Lesson 4 J. Chan notes Retrieved March 8, 2011)

- ↑ 26.0 26.1 26.2 Canadian Gov. "Agriculture Canada." The Candian Bread and Bakery Industry. Canadian Government, 8 Apr. 2009. Web. 10 Mar. 2012. <http://www.inspection.gc.ca/english/fssa/labeti/guide/ch9ae.shtml>.