Course:FNH200/2011w Team12 WhippedCream

Our team has chosen whipped cream as our food research product. The major areas of interest for this page are the history, packaging, labeling, processing and the elements that make whipped cream what it is. Whipped Cream, or whipped topping, is (whipping) cream that has been beaten until light and fluffy by an electric mixer, fork, or whisk. Whipping cream is a dairy product that contains at least 30% fat content. The high fat content of whipping cream yields a sufficiently clumped structure during aeration to facilitate rapid and complete stabilization of the incorporated air bubbles. [1] Whipped cream is a colloidal dispersion known as a foam, where the dispersed phase is a gas and the continuous phase is a liquid. [2]

Whipped cream can be sold to consumers in either a plastic tub or and aerosol can. Percentage of milk fat must be clearly stated on the label since its milk fat content is significant. It is used extensively in baking and as a topping for many desserts.

History

Whipped cream is rumored to have originated from France, where chef Vatel created a variation with sugar to serve at a reception to honour King Louis the XIV in 1661. Over the years, other flavours besides sugar have been added, vanilla being the most common. In the 1930's, the British developed aeration systems for use in the food industry, using pressurized Nitrous Oxide (N2O). In the case of pressurized whipped cream, the N2O immerses into the canned cream, and once the pressure is released, instant whipped cream is created. [3] Whipped cream can sometimes be called "Chantilly cream" when sugar is present. [4]

Imitation Whipped Cream

Whipped topping is often the name used for imitation whipped cream. It is so called because these imitations generally do not include dairy products. By avoiding the use of dairy products, these imitation whipped cream products avoid food allergies and reduce the cost of production. Whipped topping imitates real whipped cream through the use of a mixture of partially hydrogenated oil, sweeteners, stabilizers and emulsifiers.

The main ingredient in whipped topping products is water and, because all whipped toppings are sold pre-whipped, they contain a high percentage of air. Buying whipped products can cost up to twice as much as whipping real cream at home. The whipped topping brand Cool Whip has replicated the texture of real whipped cream via the use of hydrogenated coconut and palm kernel oil, both semi-solidified plant oils. Cool Whip also contains corn syrup, which is mostly glucose, and high-fructose corn syrup, which is corn syrup treated with amylase and other enzymes. [5]

Popular Brand Names

- Cool Whip is possibly the most well known of all whipped topping brands, as this brand name is often used instead of the term "whipped cream". The main ingredients are water, hydrogenated vegetable oil, high fructose corn syrup, corn syrup and real dairy cream as the 6th ingredient. There are 25 calories per 9 gram serving. [6] Varieties of Cool Whip include Regular, Extra Creamy, Seasons Delight Cinnamon, Seasons Delight Vanilla, Lite, Free, and Sugar Free. This product is packaged in both aerosol cans and plastic tubs.

- Reddi-wip brand prides itself on its use of real dairy cream as the first ingredient and does not contain hydrogenated oil. The brand has trademarked their slogan, "Nothing's more real than Reddi-wip", claiming to be more nutritious than its competitors. It contains 15 calories per 5 gram serving. Varieties of Reddi-wip include Original, Chocolate, Fat Free, and Extra Creamy. [7] This product is packaged solely in aerosol cans.

- Gay Lea Real Whipped Cream also boasts containing real pasteurized cream as the first ingredient while not containing hydrogenated oils. The two varieties are Regular and Light. There are 40 calories in a 15 gram serving of this brand. This product appears to be only available in aerosol cans. [8]

Processing

Whipped Cream is affected by the properties of the fats, temperature and stabilizers used. Before it becomes whipped cream, the whipping cream (at 36% fat) is processed at high temperature to sterilize the cream . Changes in protein and fat structure in whipped cream caused by heat treatment and addition of stabilizer to the cream. [9] The early stages of whipping the cream destabilizes the milk fat globule membranes, thus allowing partial coalescence [10]. Air is incorporated as the cream is being whipped. The product is liquid foam with a continuous liquid phase and a dispersed gas phase [2]. So a major ingredient of whipped cream is in fact air [10]. The fat globules in the cream are semi solid and exhibit a partial coalescing property [10]. This means that the fats can still retain their globular shape while having the ability to build a network or a coalesced network during the whipping [10]. During this process, air is trapped into the product. Fats have been seen to form linkages between adjacent bubbles, but proteins have been found to occupy the space between globules of fats. [11] β-casein, a sub unit of the milk protein casein and whey protein is suggested to be the initial stabilizers of air bubbles. The whipping process helps in the unfolding of proteins, which also helps improving the foaming characteristics [10]. Following this is the adsorption of fat into the globular membrane (coalesced with protein) at the air/water interface [12]

Emulsifiers and Stabilizers

Emulsifiers and stabilizers used in whipped cream are usually hydrocolloids or carbohydrates (gums) and protect the product against excessive drainage during storage by helping with structure formation. Emulsifiers migrate to the air-water interface and reduce excess surface tension. Stabilizers used to increase viscosity of the aqueous phase. They help improve texture and increase viscosity and stabilize foam. Polysaccharides, when used, function in increasing the viscosity of the aqueous phase. Reports showed that stabilized samples were more viscous, elastic and rigid. Also there are larger, smoother and rounder air bubbles in stabilized samples and no evidence of a fat layer covering the bubble layer as found in unstabilized samples. Studies shown measuring the syneresis of stabilized and non-stabilized whipping creams report that there is a large difference between the amounts of fat in the drained liquid. In addition, unstabilized whipped cream sag a significant amount more. Stabilized whipped creams drained their liquids more rapidly and as a result left dried foam that did not sag any more[10].

Fat

Fat in whipped cream is also used as a stabilizer. In whipped cream the fat content is on average 36%. When you begin to whip the cream the air bubbles that are added and mix together with the fat molecules. The fat molecules begin to form chains and air bubbles around the fat. As the fat continues to form chains and causes the cream to shape into a stiffer and smoother substance. [13]

Proteins

The protein in whipped cream also acts as a stabilizer. As air is churned into the whipped cream, the beta-casein and whey milk soluble proteins initially stabilize it. However as the mixing continues the air soon begins to be absorbed by the fat molecules. These stabilizers are either found in the milk already or added to prevent the whipped cream from becoming runny which also help it to hold its shape [13].

Beta casein is a product of carrageen. The addition of this protein also helps prevent the whey protein from separating from the dairy. However it is only used in very small amounts, usually ranging from 100-200 parts per million (ppm). [14].

Temperature

There are two main types of temperature processing of whipped cream; UHT and HTST. UHT stands for ultra high temperature treatment. The cream is heated at 140 degrees Celsius for four seconds. This is usually processed using the No-Bac Uniherm 4 processing system. HTST, high temperature short time, consists of the cream being heated to 77 degrees Celsius for eighteen seconds. The goal in heating the cream is to help preserve the product and prevent spoilage, which therefore increases shelf life. Heating the cream to a higher temperature will kill more spoilage causing bacteria, therefore the use of the Ultra High Temperature heating is ideal. In general, higher temperature processing such as UHT and HTST of whipping cream preserves the maximum firmness attainable which age [15]. However it has been found that during storage the proteins in the UHT heated cream tend to deteriorate faster then the HTST treated cream. [13].

Microbial growth

Because the water activity is above 0.90, it provides an ideal environment for microbial growth. Additionally, bacteria and microorganisms love to grow in the optimum neutral pH of 6-7.5. [16] Whipped cream is found to have a pH of 6.4, which makes it a great setting for bacterial growth. [17] Liquid foam product also allows for significant fluidity, and thus provides no physical barrier to the spreading of bacteria [16].

Some species and strains of Bacillus, Clostridium, Cornebacterium, Arthrobacter, Lactobacillus, Microbacterium, Micrococcus , and Streptococcus can survive pasteurization and grow at refrigeration temperatures which can cause spoilage problems [16]. A commonly known one is a thermophilic strain named bacillus cereus. It is known to produce cytotoxicity in whipped cream. A research done on whipped cream at 8 degrees celsius showed that there were a total of 136 bacillus cereus isolates found and with 102 strains tested positive for cytotoxin. These bacillus cereus spores are able to survive pasteurization and against the odds, certain strains are able to also multiply at low temperatures. Therefore, whipped cream must be placed in an environment under 8 degrees celsius. Some bacterial strains have been found to hydrolyze starch, but those strains that were associated with producing cytotoxins and food poisoning could not hydrolyze starch. [18]

A specific strain, BC-131, showed an increased amount of toxicity in aerated whipped cream versus just whipping cream. This shows that oxygen transfer is important in cytotoxin production[18].

Packaging

Aerosol

Aerosol packaging requires the containers or cans that are ready to be filled up with whipped cream to be rinsed and sanitized first before filling happens. The containers are then transported to a clean room for filling. After filling it with whipped cream, the cans get a spray nozzle crimped on and nitrous oxide (NO2) gas added in. Finally the cans are weighed and coded by the manufacturers. The cans are once again rinsed and labels are applied on to the cans. The labeling is passed through a heat tunnel to have them properly adhered to the cans’ surface. Lastly, the aerosol cans are packaged in boxes and ready to be transported to retailers.[19]

Plastic Tubs

Since the whipped topping has been pre-whipped by the manufacturer there is no need for the aerosol can. For the manufacturers, the plastic tubs are a more cost effective manner in which to package the whipped topping.

Whipping cream cannot be whipped after it has been frozen. Whipped cream/topping however, can be frozen for up to three weeks and thawed back to its original state. The same regulations apply for labeling as with the aerosol cans. [20]

Labeling Regulations

The regulations for labeling requirements in Canada must include the following on the whipped cream package [21]:

- % milk fat- most whipped cream have from 30-36% milk fat content

- Common name-For example, whipping cream, whipped cream/topping, heavy whipping cream

- Net quantity

- Name and address- the person or manufacturer of the whipped cream product

- List of ingredients- Descending order of proportion, each tablespoon of heavy whipped cream has about 4% daily allowance of vitamin B

- Nutrition Facts Table- Mostly indicating serving size as 1 tablespoon, 36% milk fat variety has 52 Calories per tablespoon and while table is based on 2,000 Calories/day diet. Must be visible and appear in both French and English.

- Durable life date- Required for storage life of 90 days or less

- Bilingual labeling- In Canada, all printed material must appear in both French and English. Manufacturers can choose to do a second "Nutritional Information" table, or they may combine both languages into one table. eg. Carbohydrates/Glucides 3.3 g or 1%.

Shelf Life of Whipped Cream

| Product | Temperature of the refrigerator | Shelf life of Whipped Cream! |

|---|---|---|

| Real Whipped Cream (plastic containers) | 37°F to 40° F | 3-4 weeks |

| Real Whipped Cream (aerosol can) | 37°F to 40° F | 3 months |

| Non-Diary Whipped Cream (aerosol can) | 37°F to 40° F | 3 months |

Controversy of Aerosol Cans

As mentioned previously, whipped cream packaged in aerosol cans have nitrous oxide gas added in it. Nitrous oxide, also called “laughing gas” is a chemical substance that helps dispense and whipped the cream out at the same time. Some worried that the nitrous oxide gases from whipped cream aerosol cans may be abused by some inhalant users as a recreational drug. Inhalant abuse can cause serious effects because the chemical inhaled are absorbed through the lungs into the bloodstream and quickly spread throughout different organs and the brain as well. The user can feel intoxication and other symptoms may occur, such as dizziness, headaches, abdominal pain, limb spasms, lack of coordination, loss of control, hallucinations, and impaired judgment. More severe results may also happen, such as Sudden Sniffing Death Syndrome. [23]

Whipped cream characteristics

Two important aspects to whipped cream consumers and the industry it its firmness and whipping time. Generally, milk fat content of cream determines foaminess and therefore firmness of whipped cream. A whipped cream's overrun is a measure of how much air can be incorporated into the cream during whipping to give structure and firmness [24]. In other words, a whipped cream's overrun is a measure of how firm it is.

Firmness of whipped cream

When a whipping cream is whipped, within minutes it will eventually reach maximum foam volume expansion / overrun due to incorporated air, after which foam collapses to form butter possibly due to aggregation of fat droplets [25] [26].

Without enough fat, the whipping cream won't whip, this is why whipped cream is generally made from at least 30% - 36% fat content cream. With increasing fat content, the whipped cream produced will have higher overrun and therefore will be more firm. Generally, lower fat content leads to a softer foam / less overrun. [25].

However, as we increase the % fat content beyond 36%, maximum overrun that could be achieved also decreases [25]. This is why whipped cream made from heavy whipping cream (40% fat content) has less firmness and structure compared to whipped cream from regular (36% fat content) whipping cream.

In addition to fat content, firmness of whipped cream decreases with the age of the whipping cream [15]. A major use of whipped cream is in cake fillings, which often requires firm whipped cream. Dairy companies suffer substantial financial loss in premature collapse of whipped cream for cake fillings due to loss of firmness [25]. Some of the ways that we can preserve the ability of cream to form firm whipped cream is through temperature processing and stabilizers, as we have discussed before. The higher the processing temperature, the slower the maximum overrun attained from whipping cream is diminished with age of the cream [15].

Whipping time

In conjunction with increased firmness with increasing fat content (maximum at 36%), whipping time continually decreases with increasing fat content [25]. This is why heavy whipping cream is much faster to whip compared to light and regular whipping cream. As much as age of whipping cream negatively affects the firmness of whipped cream produce, age will also increase the time it takes for a cream to reach its maximum attainable overrun/firmness [15]. It is important to note that although maximum overrun increases with fat content, the time it takes to over-whip and butter also decreases.

Summary and Reflection

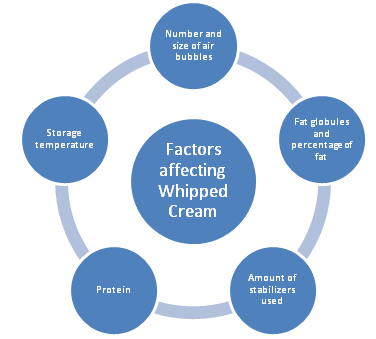

Whipping cream is a dairy product with at least 30% milk fat which acts as a stabilizer for the air bubbles. Air is whipped into the cream by beating it with a fork, whisk, or mixer until it becomes a fluffy foam. This product has a history dating as far back as the 1600's in the kingdom of King Louis the XIV. There are several products on the market which offer a certain variation of whipped cream. Real whipped cream is usually purchased in a carton and comes in a liquid form; it is the consumer who may choose to whip the cream themselves for further processing. Imitation whipped topping is sold pre-whipped and usually does not contain real dairy products and can be heavy in hydrogenated oils, sweeteners, stabilizers and emulsifiers. This form, is either sold in aerosol cans, or plastic tubs. The nitrous oxide aeration systems for aerosol cans was developed in the 1930's. The most popular brand names of whipped cream are Cool Whip, Reddi-wip and Gay Lea Real Whipped Cream. All three contain various ingredients and flavours. The cream that is sold in aerosol cans are first sanitized before being filled with whipping cream. Once the cans are filled in, nitrous oxide is added. The cans are weighed and then sanitized again before being transported to retailers. You can also purchase the pre-whipped cream in plastic tubs which is more affordable for manufactures and convenient for consumers. There is a difference in storage life for each type of packaging. Real whipped cream in aerosol cans can be stored up to 3 months, while whipped cream packaged in plastic containers can only be stored up to 3 to 4 weeks. The labeling requirements for whipped cream are the same as in any dairy product sold in Canada. Specifically the label must be in both French and English and the "percent milk fat" must be clearly displayed. The texture of whipped cream is sensitive to many factors and can be affected by the temperature of storage, the protein used, and the number and size of the air bubbles. Additionally, the amount and type of stabilizers used is determined by the fat globules and percentage of fat in the whipped cream.

References

- ↑ Allen, K. (2008) Development of a model whipped cream: Effects of emulsion droplet liquid/solid character and added hydrocolloid. Food Hydrocolloids. 22, 4.

- ↑ 2.0 2.1 Chan, J. (2012). UBC Wiki. Retrieved 13:57, March 14, 2012 from http://wiki.ubc.ca/Course:FNH200/Lesson_02

- ↑ Menelley, D. (2010). The History of Whipped Cream. EzineArticles.com. Retrieved from: http://ezinearticles.com/?The-History-of-Whipped-Cream&id=5009679.

- ↑ Herve, T. (2002) Molecular Gastronomy. Angewandte Chemie International Edition. 41, 1.

- ↑ Di Justo, P. (2007). Cool Whip. Wired Magazine: 15.05. Retrieved 13:00, March 14, 2012 from: http://www.wired.com/wired/archive/15.05/st_coolwhip.html

- ↑ Kraft Corporation. (2012). Product Info: Original Cool Whip. Retrieved 14:20, March 14, 2012 from: http://www.kraftbrands.com/coolwhip/coolwhipproducts.aspx

- ↑ ConAgra Foods. (2012). Reddi-wip: Real Cream Advantage. Retrieved 14:52 on March 14, 2012 from: http://www.reddiwip.com/real-cream-advantage.jsp

- ↑ Gay Lea. (2011-2012). Whipped Cream: Regular. Retrieved 15:11 on March 14, 2011 from: http://www.gaylea.com/products/prodid/15

- ↑ Smith, A. K., Kakuda, Y., & Goff, H.D. (2000). Changes in protein and fat structure in whipped cream caused by heat treatment and addition of stabilizer to the cream. Department of Food Science, 33, 697-706.

- ↑ 10.0 10.1 10.2 10.3 10.4 10.5 Stanley, D.W., Goff, H.D., & Smith, A.K. (1996). Texture-structure relationships in foamed dairy emulsions. Department of Food Science, 29(1), 1-13.

- ↑ Anderson, M., Brooker, B.E. (1988). Dairy Foams.E. Dickinson, G. Stainsby (Eds.), Advances in Food Emulsions and Foams, Elsevier Applied Science, pp. 221–255

- ↑ Goff, H.D., Verespej, E., & Smith, A.K. (2000). A study of fat and air structures in ice cream. Department of Food Science, 9, 817-829.

- ↑ 13.0 13.1 13.2 A.K Smith, Y Kakuda, H.D Goff, Changes in protein and fat structure in whipped cream caused by heat treatment and addition of stabilizer to the cream, Food Research International, Volume 33, Issue 8, October 2000, Pages 697-706, ISSN 0963-9969, 10.1016/S0963-9969(00)00115-0. (http://www.sciencedirect.com/science/article/pii/S0963996900001150)

- ↑ Imeson, A. (2010).

- ↑ 15.0 15.1 15.2 15.3 Bruhn, C.M. & Bruhn, J.C. (1988). Observations on the whipping characteristics of cream. Journal of Dairy Research, 71(3), 857-862.

- ↑ 16.0 16.1 16.2 Goff, D. (2011). Dairy Microbiology. Retrieved from http://www.foodsci.uoguelph.ca/dairyedu/micro.html

- ↑ Universo Lacteo. (2012). Spray Whipped Cream. Retrieved from Universo Lacteo website: http://www.universolacteo.com/specs/CremaSpray.pdf

- ↑ 18.0 18.1 Christiansson, A., Naidu, A.S., Nilsson, I., Wadstrom, T., & Pettersson, H.E. (1989). Toxin Production by Bacillus cereus Dairy Isolates in Milk at Low Temperatures. Applied and Environmental Microbiology. 55(10), 2595-2600.

- ↑ Joseph, A. (2011) Whipped Into Shape. Retrieved from: http://www.labelad.com/userfiles/file/Gaylea%20-%20Cdn%20Pkg.pdf.

- ↑ 20.0 20.1 Garden-Robinson J. (2012) Food Storage Guide. Retrieved from:http://www.ag.ndsu.edu/pubs/yf/foods/fn579.pdf

- ↑ Chan, J. (2012). UBC Wiki. Retrieved 23:29, March 12, 2012 from http://wiki.ubc.ca/Course:FNH200/Lesson_04.

- ↑ Shelf Life Advice. (2009) Whipped Topping/Whipped Cream. Retrieved from:http://shelflifeadvice.com/dairy/cream-and-cream-products/whipped-cream

- ↑ Alliance for Consumer Education. (2011) Canned Whipped Creams and Toppings. Retrieved from: http://www.inhalant.org/media/whip.html.

- ↑ http://specializedequip.com/overun.htm

- ↑ 25.0 25.1 25.2 25.3 25.4 Muir, D.D., Banks, J.M., Powell, A.K., & Sweetsur, A.W.M. (1983). Milk composition - manufacturing properties. Proc. Nutr. Soc., 42, 385-397.

- ↑ Jakubczyk, E., Niranjan, K., (2006). Transient development of whipped cream properties. Journal of Food Engineering., 77(1), 79-83.