Course:FNH200/2013w Team13 Beer

Beer has been considered to be the origin of fermentation, dating back to the Mesopotamian era of around 5000 BC. Its physio-chemical qualities allow for it to be used a variety of ways and play a role in different religion, cultures, and ethnic groups. In Egyptian legend, they believed that Osiris, the god of earth and vegetation, was the one who discovered beer. [1]

Today, it is one of the most popular and most consumed alcoholic beverages across many cultures and societies. It’s associated to many of today’s social customs such as pub crawling and “beer fests”. To demonstrate the value of beer in today’s cultures, average annual consumption of beer is 86kg/capita in North America and 74 kg/capita in Europe[3]

Team Video

Beer Production

Depending on the grain—malt extracts, specialty grains, all-grain—utilized for the production of the sugars necessary for fermentation, different types of beer can be produced. In addition to the type of grain used, further steps are necessary in order to ensure the quality of the beer to be top notch, both when produced in small batches at home or large quantities in breweries. The different types of beer are brewed differently from one another. However, the underlying steps in the production of the different beer varieties remain the same. While the ingredients may vary from one type of beer to another, their functions remain nonetheless similar.

In beers that use malt extract[4], the first step in production is soaking malted barley in hot water, which releases maltose sugars; they are crucial nutrients that yeast utilizes while undergoing fermentation. Following that, the solution is boiled alongside hops in order to add flavor and act as a stabilizing agent.

Hops are part of the cannabis family. Their release of alpha acids contributes to the bitterness of the beer. As the hops are heated to a high temperature, the aroma of the hops start to fade; the bitterness the only characteristic remaining. Therefore, the typical brewery would have multiple hop additions. The primary bitterness will be derived from the initial addition of hops and the final aroma of the beer is derived from the later additions.

The next step includes the cooling of the boiling solution to a reasonable temperature. Yeast is then added into the solution to initiate the fermentation process. Fermentation is what occurs when sugars present within the beer are broken down by yeast during their fermentative process. It yields ethyl alcohol and carbon dioxide, both of which are part of the characteristic qualities of beer. When this main step of fermentation is complete, a small amount of sugar is added as the beer is bottled and packaged, giving the beer its carbonated taste. There is also an aspect of cold aging required for brewing beer. Beer is stored at a lower temperature for further maturation and enhancement of flavors and aromas.

In order to yield the different types of beers, types of malt, temperature, types of yeast, and time all contribute to certain characteristics that produce the variances in flavor and alcoholic content. The amount of malt determines how strong the beer will be and the type of malt determines how dark a beer will be. The different temperatures will vary the functionality of the yeast. Thus, the beers need to be stored at an optimal temperature for yeast function. At the Buckbean Brewing Company[5] in Reno, Nevada, the two types of yeast used in their fermentation process are ale yeast and lager yeast. These have lead to the production of the commonly sold ales and lagers. Ale yeast and lager yeast both contribute to the various flavor profiles of beer:

- Ale yeast ferments much faster and at warmer temperatures, whereas

- Lager yeast ferments much slower at cooler temperatures and thus requires extra time for maturation.

Ale yeast also synthesizes various ester compounds, which gives the beer a more ‘fruity’ flavor. Ale only requires around a week of cold aging before it can be packaged and distributed, whereas lager needs to cold age for at least 2 weeks.

Beer Content

In the past, while beer has been produced using very similar recipes with similar contents, nowadays, beer comes in a variety of new and ever-so-changing ingredients. There are so many varieties of beer that each beer carries its own distinctive taste, aroma, and appearance, and most importantly, contents and nutritional value. Though beer is commonly composed of water, grain, hops, and yeast, there are many factors that may affect a beer’s tastes and contents, such as its bitterness and alcoholic content.

Carbohydrates (starch) are the essential ingredient that determines the strength and primary flavor of the beer. Wheat beer utilizes wheat as its starch source, whereas high-gravity beer has a higher carbohydrate content and thus has a higher alcoholic level. The choice of malt used will determine a beer’s color, which may range from pale amber to dark brown. Dark beers, such as stout and porter, get their color from the dark roasted malted barley used during the brewing process.

While these ingredients dictate the general appearance and taste in beer, there are also other constituents that people are mostly unaware of. Certain beers contain contents such as genetically modified organisms (GMOs) and monosodium glutamate (MSG). GMOs are generally used to give beer a lighter and milder taste. MSG is mostly produced during the fermentation process and plays a role in how the beer tastes and contributes to the umami flavor of some types of beers. Moreover, beer also contains B vitamins, potassium, calcium, and various other minerals that promote a nutritious diet. Beer also contains silicon, which can improve bone strength and health and is only found in a few food sources.

Nitrosamines

Beer also contains nitrosamines, which have been found to cause cancer. However, its carcinogenic property that raised most concerns in the 1980s has been greatly reduced as today’s production technologies have improved. The nitrosamines (DMNA) may be formed during the direct-fire drying of barley malt. By converting the process from direct-fire drying to indirect-fire drying, the nitrosating agents and the formation of dimethylnitrosamine have been markedly reduced. Currently, beer only contains only 2% of the amount of dimethylnitrosamine that used to be present 20 years ago. It is also very rare in beer common to the North American market.

Uses of Beer

Historical Facts About Beer

Beer has a variety of uses. In its diverse history, beer has not only been used for beverage consumption but has also been used for various curative purposes. Examples of its curative uses include[7]:

- Mouthwash

- Enema

- Vaginal douche

- For treatment of injuries and cuts

Current Uses

In today’s societies and cultures, beer mostly serves as a tool for engagement between people. Whether it is consumed in bars during sporting events or at celebration and parties, the consumption of beer is often used to facilitate interaction amongst people. However, to prevent the injurious and dangerous effects that it may have on children if they consume beer, present-day society has set age regulations for when an individual is legally allowed to consume beer. In most countries, children must be over 16- 21 years old in order to be able to purchase and legally drink beer [7].

Aside from the consumption of beer as a beverage, it also acts as an ingredient found in shampoos as well as in different recipes for cooking.

Beer and Nutrition

Currently, more and more research is being done that continue to show that alcohol consumption, including beer, can contribute to the nutrition and health of individuals if taken in moderation and balance. As we have seen, studies have continued to show the health benefits of drinking red wine in moderation can provide people. In Japan, evidence has been found that shows how alcohol causes greater production of the serum HDL lipoprotein cholesterol, which aids in decreasing the negative effects of cholesterol in the blood vessels[7]. As Denke has stated, we can define drinking in moderation as “1 day per drink for women and 2 drinks per day for men”[9].

As for beer, there have researches that show the advantageous effects that beer can have for our bodies in the prevention of cardiovascular diseases by lowering stress levels. Studies have even gone as far as to show that any consumption of alcoholic beverage (in moderation) can be beneficial for our health since alcohol is correlated with a decrease in the rate of occurrence of heart diseases. In comparison to wine, beer has higher protein, B-Vitamin (riboflavin, niacin, thiamine, pyridoxine), mineral, and fibre content. The dietary fibre content found beer is between 0.4 and 6.2 g/L[7]. Beer also contains antioxidants—substances that prevent tissue damage during oxidation as well as function to prohibit the growth of chronic diseases such as cancer, stroke, Alzheimer’s disease and cataracts.

Back in the 18th century, yeast was added into beer. The vitamin content of yeast added to the nutritional value of beer. This has contributed to lower deficiency (such as beri beri) and neural diseases. In the older population, beer has been shown to stimulate their appetites and bowel movements, which decrease as they continue to age[7]. Beer also contains folic acid, which aids in lowering the homocysteine—contributes to vascular disease—content in blood. Research has shown that individuals that consumed beer as opposed to spirit or alcohol were found to have significantly lower serum concentrations of homocysteine[7].

Despite the benefits that research has shown that beer can have when taken in moderation, physicians have yet to authorize people to consume beer for fear that they may simply take advantage of this privilege and consume beer in excess amounts, which can be very hazardous to the body.

Labelling and Regulations

Beer labels must meet the standards set out by the Canadian Food Inspection Agency. The labels must include the following:

- Common name of the food

- Net quantity

- Name and address of the person responsible for the food

- Percent alcohol content

- Bilingual labeling

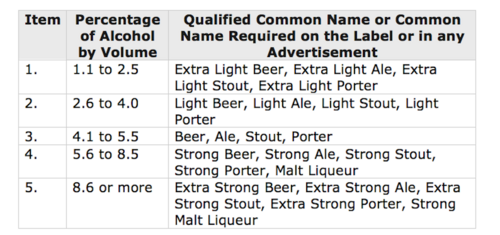

However, standardized alcoholic beverages are exempt from requiring a nutrition facts table and listing all ingredients,[10]. In order to have the common name of “beer” on the label, the percentage of alcohol, by volume, must be 4.1 to 5.5 percent. The full table of common names is shown below. [10]

In 2012, new labelling requirements were introduced that made it mandatory for standardized alcoholic beverages to declare added allergens, gluten sources and sulphites at levels of 10 ppm or more. The new labelling requirements do not yet apply to standardized beer, ale, stout, porter or malt liquor products. However, these products will be dealt with once further consultations and discussions can be held by Health Canada[10].

Gluten-Free Beer

While avoiding gluten is critical to the health of individuals with celiac disease, a gluten free diet is also undertaken by those with wheat intolerances and, as seen in recent years, individuals who believe that a gluten free diet is healthier. The trend of gluten free diets has prompted an increase in production of gluten free products, with sales increasing from 4.8 billion dollars in 2009 to 6.1 billion dollars in 2011 [3]. The Food and Drug Regulations of Canada “prohibits the labelling, packaging, advertising or sale of a food in a manner likely to create an impression that it is a gluten free food if the food contains any gluten protein or modified gluten protein, including any gluten protein fraction, from wheat (including spelt and kamut), oats, barley, rye, triticale or their hybridized strains”[11]. These requirements do not refer to any specific threshold for gluten in products represented as "gluten-free". However, Health Canada considers that levels of gluten protein below 20 ppm generally do not represent health risks to consumers with celiac disease[11].

Most beers brewed from barley or wheat-based malt are generally considered unsafe for individuals suffering from celiac disease. During traditional beer processing, modification and removal of proteins occur and the amount of “harmful” gluten remaining in final products is now in question. Further, beer often contains significant quantities of gluten free adjuncts, which ‘dilute’ the initial raw material gluten content. Researchers have found that up to 83% of the beers on the market could be considered gluten free[3]. According to Health Canada, if a beer is made with barley and it can be demonstrated that the gluten has been removed through specific process, a “gluten-free” claim can be made if the beer consistently tests negative or less than 20 ppm gluten[11]. Grains such as rice, corn, sorghum or millet can also be used to produce naturally gluten free beers[3]. Any information about gluten currently on beer labels is at the discretion of producers and is directly affected by the growing demand for and increased revenue from gluten-free products.

Packaging

Packaging is of similar importance as the brewing process since the quality/type of packaging can determine how well the beer tastes once it leaves the brewery. In particular, proper packaging can aid in withstanding the negative effects that light and oxygen can have on the beer. After the fermentation process, beer is usually packaged into the following:

- Bottles

- Cans

- Casks (for cask ale)

- Kegs

Bottles

Since its invention about 440 years ago, beer bottles have been used to package beer of all sorts. From still beer to beer that’s already been carbonated at the brewery, brewers have utilized bottles for their protective properties. Aside from being able to protect the quality of the beer, bottles are also easier to transport (in comparison to kegs and casks) and thus made exporting beer a lot easier, especially earlier in history when technology wasn’t what it is today.

A properly sealed bottle (typically using metal caps) can protect its beer content from being oxidized by oxygen for a long period of time. Most beer bottles have a dark amber or a brown glass color. This is to reduce the negative effect that light, in particular UV light, can have on the beer. If exposed to light, the molecule 3-methylbut-2-ene-1-thiol results (due to reaction of riboflavin and the breakdown of isohumulones) in a “skunky” beer, beer with unpalatable taste and odor[13].

Cans

Beer cans can be seen as miniature kegs because they offer very similar protective qualities as kegs do, except without the need for a pressure system. They’re metallic (usually Aluminum) outer layer doesn’t allow for light to pass through and negatively affect the quality of the beer. Unlike improperly-sealed bottles that can have oxygen leak through under the cap, cans are airtight and are able to remain free of oxygen and not allow it to affect the beer contained within. Another advantage that cans have over bottles is that they can be discarded much easier in comparison to the glass bottles and are much lighter in weight.

Much like bottles, beers stored in cans allow for greater convenience and portability due to its smaller size. As for fear of metal contamination, the insides of the can are sprayed with a water-based polymer (such as epoxy resin) that ensures no contact between the metal can and the beer. However, there is still a chance that trace amounts of metal can be degraded into the beer[14].

Casks

Casks are very similar to kegs but they differ in the type of beer that they contain as well as some of their dimensions. Casks are mainly used to contain cask ale. It differs from the beer stored in kegs in that it is unpasteurized and contain yeast. Cask ale is also fermented twice and does not “fizz” because it has no added gas (since the yeast produces natural ).

A cask may have two (or more) openings and lack the ‘spear’ that’s present in kegs. They also have a ‘handpull’ on the bar; it is how cask ale is served out of the cask. Since it still contains a living product and remains unfinished upon leaving the brewery, a cask must be sold within 72 hours for the best quality. They need to be stored at a cool temperature (C) for proper savory of the flavors and aromas and to allow for the beer to settle. Much like kegs, casks’ material does not allow for light to pass through and affect the beer as well[15].

Kegs

Beer can be stored in kegs, which are most commonly made of stainless steel. Inside, it contains a tube (called a ‘spear’) from which gas, usually , can drive the beer out of the keg. Kegs usually contain beer that’s been filtered, pasteurized, and have had gases added into it (most commonly and nitrogen). Since it’s entirely made out of metal (stainless steel), light can’t get through and affect the beer within. To maintain the pressure on the beer as well as keep it carbonated and protect it from oxygen, gas is forced in as beer is dispensed from the keg.

Kegs are stored in cool temperatures, anywhere from C all the way down to C. Due to the added gas, beer stored in kegs has that ‘fizziness’ quality that’s lacking from cask ale. Also, unlike cask ale, keg beer only goes through fermentation once and contains no live yeast. Beer from a keg is ready to be served once it is packaged[15].

Team Exam Question

A new company has created a new alcoholic beverage with an alcohol content of 3.5%. According to Canadian Food Inspection Regulations Beer the label must declare which of the following:

- Common name—Beer

- List of ingredients

- Nutrition facts table

- Percent alcohol content

Answer: Percent alcohol content

References

- ↑ Hornsey, I. S. (2003). A history of beer and brewing. Cambridge: Royal Society of Chemistry.

- ↑ Beer Sampler[Photograph] Retrieved from <https://www.flickr.com/photos/quinndombrowski/5200218267/>/

- ↑ 3.0 3.1 3.2 3.3 Hager, A., Taylor, J.P., Waters, D.M., & Arendt, E.K. (2014). Gluten free beer-A Review. Trends in Food Science & Technology, 36, 44-54.

- ↑ Palmer, J. (n.d.). How to Brew - By John Palmer - Introduction. How to Brew - By John Palmer - Introduction. Retrieved March 16, 2014, from http://www.howtobrew.com/intro.html

- ↑ Kahn, D. (2010, May 18). How is Beer Made? The Brewing Process. YouTube. Retrieved March 30, 2014, from https://www.youtube.com/watch?v=Ycnwc5vPaAo

- ↑ Bell's Beer Sampler[Photograph] Retrieved from <https://www.flickr.com/photos/brostad/4748821712/>/

- ↑ 7.0 7.1 7.2 7.3 7.4 7.5 Bamforth, C. (2002). Nutritional aspects of beer—a review. Nutrition Research, 22(1-2), 227-237.

- ↑ Deceptive Packaging- Pantene Shampoo[Photograph] Retrieved from http://www.flickr.com/photos/albaum/1356519213/

- ↑ Denke, M. A. (2000). Nutritional and Health Benefits of Beer. the american journal of the medical sciences, 320(5), 320-326.

- ↑ 10.0 10.1 10.2 Canadian Food Inspection Agency. (2014). Labelling Requirements for Alcohol. Web. <http://www.inspection.gc.ca/food/labelling/food-labelling-for-industry/alcohol/eng/1392909001375/1392909133296>

- ↑ 11.0 11.1 11.2 Canadian Food Inspection Agency. (2013). Gluten-Free Claims. Web <http://www.inspection.gc.ca/food/labelling/food-labelling-for-industry/allergens-and-gluten/eng/1388152325341/1388152326591?chap=2>

- ↑ Hugger Industries. (2010). Gluten Free Beer. Retrieved from https://www.flickr.com/photos/huggerindustries/4847590113/in/photostream/

- ↑ Lindsey, Bill. "Beer & Ale Bottles." Beer & Ale Bottles., 10 Mar. 2014. Web. <http://www.sha.org/bottle/beer.htm>

- ↑ "Beverage Cans." Ball. Web. <http://www.ball.com/beverage-containers/>

- ↑ 15.0 15.1 "Cask vs Keg? - Cask Marque." Cask vs Keg? - Cask Marque. MerritWeb. Web.<http://www.cask-marque.co.uk/beer-information/cask-vs-keg>

- ↑ Keg [Photograph] Retrieved from http://en.wikipedia.org/wiki/Keg