Course:FNH200/2011w Team09 Whiskey

Production of Scotch Malt Whisky

Introduction

Every great achievement begins with a single step, and the unique characteristics of each malted Scotch whisky starts with a single malt. Its fresh and distinctive flavor is a result of fermentation of grains, distillation, and aging in wood. But just how is it that they go from the fields to the flasks? We are going to explore this journey of whisky.

The barley is at the base of the entire process. The quality of the barley has a great influence on the quality of the end product. The combination of malted barley, yeast and quality water are what provide the key taste of whisky. After all, the malted barley is the basic ingredient which will determine the quality of the whisky which will be sold years later. In addition to its ingredients, the manufacturing steps; malting, smashing, fermentation, distillation and maturation all function to give whisky its alcohol content and pure taste. The maturation process is one of the most important when it comes to generating the distinct whisky taste and aroma. Often whisky is aged for a fixed period of time in oak casks to give it some new fragrances before bottling.

Why We're Interested

Single malt scotch whisky is a representative of Scottish culture and tradition. Enjoyed all over the world, single malt scotch whiskey is produced with pride only in Scotland. Though considered a luxury, this cherished drink is certainly taken seriously. As a celebration of its 125th birthday, top-selling company Glenfiddich released only eleven bottles of a fifty five year old single malt scotch. The first bottle sold as the most expensive in history at $72,630! [1]

The legal definition of single malt Scotch whisky as defined by the Scotch Whisky Act, effected 1990, is a whisky that has been produced in Scotland from malted barley and water. Single whisky is one that has not been blended, and is the product of only one distillery. The distilled product must be matured in Scotland in oak casks less than 700 liters in volume, for at least three years. The whisky must retain the colour, aroma and taste derived from the raw materials, water and fermented barely distillate. [2]

There are two recognized spellings of whisky/whiskey. Both are correct, however for trade purposes ‘whiskey’ refers to Irish Whiskey and ‘whisky’ refers to Scottish Whisky. [2]

Malting

Malted barley is the main cereal used in whisky production. Barley is a cereal similar to wheat and oats. The two species of barley used most often are Hordeum vulgare L. and Hordeum distichon. [3] Malted barley is used as a source of amylolytic enzymes that catalyze the hydrolysis of starches and in some cases serves as a source of starch that is converted ultimately into ethanol. [4]

The malt used in whisky is germinated barley that has been dried by a process called malting. The objective of malting is to develop enzymes required to modify the grain's starches into sugars. It converts insoluble starch to soluble starch and reduces complex proteins. It also develops other enzymes, such as proteases which break down the proteins in the grain into forms that can be used by yeast. This malting process is carried out in three stages, steeping, germinating and kilning or drying. [4]

Druring the steeping cycle the barley kernels are soaked in hot water for approximately 60-hours to raise the moisture level and activate the metabolic processes of the dormant kernel. This is done to allow uniform growth during germination. [4]

In the course of germination, barley is maintained at a suitable temperature and humidity level until germination occurs. Pneumatic malting is the most common way of germination. [5] This process uses forced air for the germination process. Temperature controlled air that is saturated with moisture to a humidity of 100%, is passed through germinating grain contained in a concrete box with holes in the box floor. This system provides ideal conditions for the germination of the barley to proceed. The malt at the end of the germination process is called “green malt”. [5]

The final step is to dry the green malt in the kiln, which is done at different temperatures. The temperature regime in the kiln determines the color of the malt and the number of enzymes which survive for use in the mashing process. [5] The Kiln is a tower shaped structure with a furnace at the base. The hot air chamber is located above the furnace. It distributes the heat from the furnace evenly under the wedge wire floor where the malt has been spread. The wedge wire floor is constructed as to allow an easy passage for the hot air to pass through the grain. The upward draught of hot air may be natural but is often assisted by a powered fan. [5]

The main purpose of drying the grain is to perform the following functions:

- It stops germination and fixes the Enzymes. [4]

- It physically changes and forms the malt into a condition suitable for milling or grinding at a subsequent stage. [4]

- It imparts a flavor to the malt as a result of the use of peat in the furnace. [4]

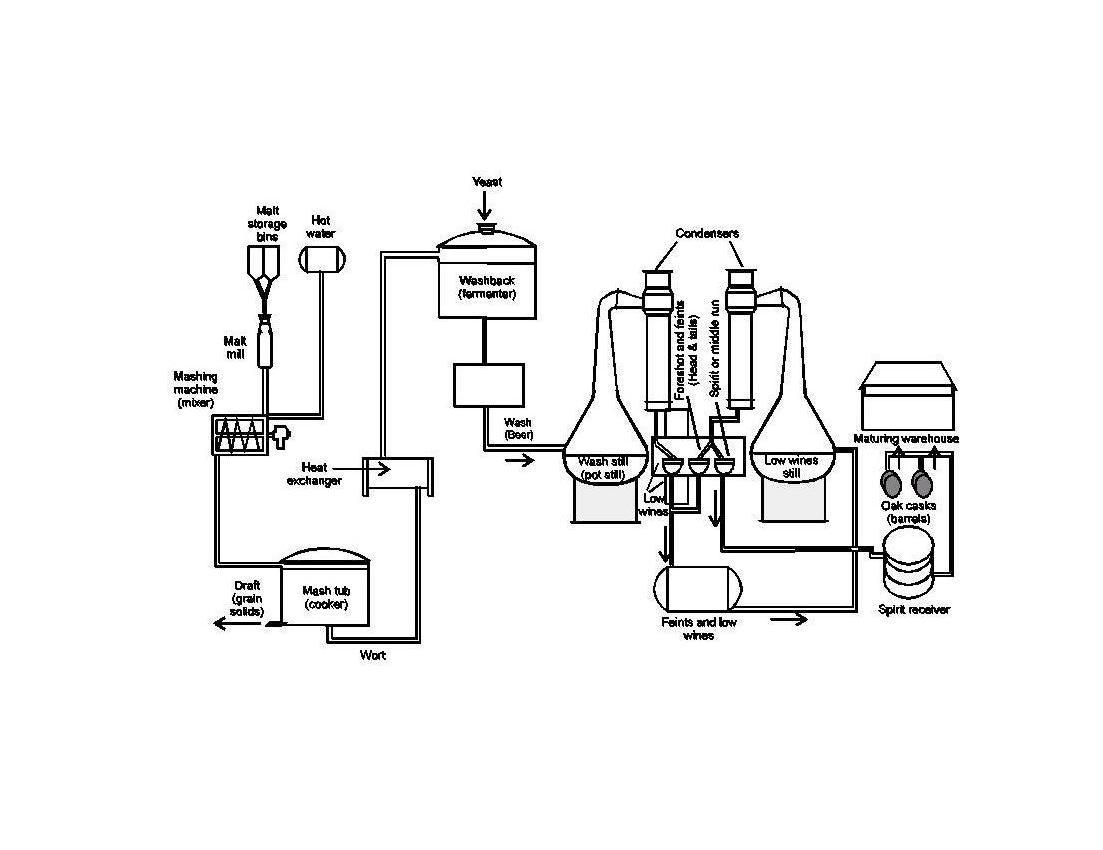

Mashing

The object of mashing is to become soluble and to dissolve as much of the valuable contents of the malt as is possible. This produces a sweet liquid or sugar solution termed Wort. The main biochemical changes that take place during mashing is the hydrolysis of starch and proteins to produce water soluble low molecular weight compounds that form a fermentable substrate called wort. The major starch-liquefying and saccharifying enzyme is ß-amylases. [4]

The mashing process uses water and ground malted barley. The quality of the water is an important factor in the quality of the spirit produced. All waters differ to some extent in the quantity and type of minerals and organisms contained in them. Generally, hard waters are considered unsuitable and soft waters are preferred. Ideal water would be one from a whinstone or granite strata, which is acid in nature and flowing through peaty soil with a minimum of metal content. [4] The barley malt contains a high amount of starch and enzymes that have the ability to convert starch to sugar when mixed or mashed with water. The enzymic action that takes place is influenced by temperature, PH and concentration of the mash.

The malt used in whiskey production is grounded in a roller mill and turned to a semi-fine grind. The malt is then mixed with hot water at 60-65°C and the mash is made uniform by revolving rakes. Then the mashed malt is left to stand for about one hour, after which the wort is drained from it. This liquid extract is collected in an intermediate vessel known as an underback. After being cooled to about 25°C in a heat exchanger, the wort is pumped into the fermentation vessel and the process continues for a few cycles.

Fermentation

There are many different species of yeast but the one normally used in whisky production is called Saccharomyces Cerevisiae. The objective of using Saccharomyces cerevisiae is to convert the sugars from the mash to ethanol and carbon dioxide while minimizing the production of other organic compounds that could contribute to the organoleptic qualities of the final distilled product. [4]

When yeast is introduced into a sugar solution such as Wort there are three ways in which it utilizes the sugar. [4]

- For multiplication i.e. it uses sugar to form new cell material.

- Fermentation: - This is an anaerobic reaction in that it occurs in the absence of air.

- Respiration: - This is an aerobic reaction and occurs if a constant source of oxygen is available.

The yeast is added as soon as possible to the cooled wort being pumped into the wash back. This is done in the very early stages in order to quickly star fermentation. It is more readily done by providing the yeast with the ideal nutrient. The ideal nutrients for the yeast are in the wort of the initial liquor from the first water. [6]

The first wort is removed, cooled, and pumped to the fermentation vessel. Then added to the second water. The second water is processed at a higher temperature to effect the maximal extraction of carbohydrate from the malt. The removed wort is cooled and added to the first wort to fill the fermentation vessel.

There are three phases in which yeast goes through during fermentation. The first one is the lag phase where there is little fermentation. Here, the yeast is just adapting to its new surroundings. The second phase is the log phase, where there is rapid fermentation due to a rapid rise in temperature. Fermentation is so vigorous that rotating metal blades must be activated to keep down the frothy head. The last phase is where fermentation slows down and eventually stops. [4]

Distillation

Distillation is the final process before the maturation of the whisky can begin and the particular characteristics of whisky can develop. Distillation is the process of evaporation and then condensation of a liquid. This is done so that there is a separation from the different substances involved. In whisky the purpose is to separate the water and other substances from the alcohol.

For malt whisky the process of distillation happens in copper stills. Stills are large containers that are round at the bottom and rise up to a narrower end. The purpose of the still is to remove the impurities that are in the wash. For the whisky to be fully distilled it has to go through two different stills. The first still is called the wash still. In the wash still the liquid vaporizes and goes to the top of the wash still, and it is at the top where it condenses. The liquid, which has an alcohol content of 7-30%, is now called low wine. It is then transferred to the next still. The second still is called the spirit still because it is here that the finial product called spirit is extracted. During the finial distillation there are three layers of alcohols that arise. [7]

The first alcohol that rises to the top is called foreshots it has a very high alcohol percentage but it is also has a strong bitter taste. [8] This liquid is the most volatile, meaning that is evaporates the quickest. This layer usually contains methanol. Methanol (CH3OH) is a chemical that is very volatile and flammable and it is the simplest form of alcohol. Methanol, when in air, burns to form carbon dioxide and water.

2CH3OH + 3O2 → 2CO2 + 4H20

The middle layer that arises from distillation is the alcohol that is used. It is carefully removed and gathered through the spirit safe. It is now called the spirit and the alcohol content is reduced with the addition of water o 60-70% [7].

The last layer is the called the feints which has a very low alcohol percentage but also has a very strong bitter taste. The foreshots and the feints mix together and return to the first still. [8] The spirit is then taken to the next step where it is matured so that it can eventually become whisky. [9]

Maturation

The spirt is then put in malt whisky cask, where it is kept for numerous years to develop the particular scent and taste whisky is known to have.[7] During the time of maturation, the whisky 'breathes' as it is subjected to periods of heating and cooling. During these cycles, 1-2% of the whiskey is lost through evaporation called the ‘angels share’. The whisky will be subjected to a relatively narrow temperature range, varying only by about three degrees Celsius, the maximum temperature will rarely reach over 32 degrees celsius. Acceleration in the aging process can be accomplished by increasing the heating and cooling cycles. [10] The whiskey’s maturation in the casks is monitored through sampling until the whiskey reaches its desired qualities.[11]

Cask of Choice: American White Oak

Detailed variations between cask types play a critical role in defining the quality of whisky. New or unaged whiskey is placed into internally charred new American Oak casks. While in contact with the inner surfaces of the cask, the whisky slowly absorbs colour, flavour, and aroma from the wood. This makes the wood itself and its interaction with the whisky play a central role in the whisky making process. Controlled heating and cooling can increase or decrease the rate of reactions between the wood and whisky.[12] Higher temperatures result in higher humidity, causing more alcohol content than water content to evaporate, ultimately lowering the whisky’s strength. Lower temperatures have the opposite effect by causing lower humidity, relatively more evaporation of water content, and increased alcohol strength.

American (White) Oak is the wood of choice due to its characteristics of natural compounds which react with whisky in the most desirable fashion. The influence of casks on the final whisky product begins from the very creation of the cask. When oak casks are made, heat must be applied in order to shape the barrels. When oak is heated, hemicellulose is broken down into simple sugars. The inner surface of each cask is set on fire for forty seconds to four minutes in order to char the surface. The amount of charring will affect the reactivity between the wood and the whisky. More charring will produce more vanillin, lactones, and tannins, as well as extracting sulphur out of unaged whiskey. During charring, the simple sugars become caramelized adding to the rich colour and flavour.[13]

The compound lignin holds the oak’s cellulose together and when heated, produces vanillin (vanilla flavour). Oak tannins react with chemicals in the whisky through oxidation forming acetals (fruity flavour). Lactones present in oak wood contribute to the woody or coconut flavour. American Oak is preferred over similar oaks primarily for its high lactone content.[14]

As casks are reused, the wood losses some its contributing materials producing milder flavoured whisky as some of the desired materials have been depleted. In the United States, government regulations require all malt whiskys to be aged in charred new oak casks for at least 2 years.[15] Canadian regulations require whiskey to “be aged in small wood for not less than three years.”[16]

Ethanolysis

There are numerous microbiological changes that occur within the maturation of the liquid so that it develops the common whiskey traits known to the whisky drinker. The changes are mostly due to ethanolysis. Ethanolysis is the degradation of ethanol. Ethanol, more commonly known as pure alcohol, is a very volatile and flammable substance. This process is very important to the production of whisky because ethanol (C2H6O) is the main part of whisky, that gives whisky sweetness and bitterness components and also stimulates the epidermal mucous membranes. These membrane are made up of epithelial tissue and their function is to secrete mucous in the body. These line many of the body’s cavities including the digestive tract and the gut. The degradation of ethanol releases different compounds, one of the most important is polyphenols. Polyphenols is known as the substance that gives the smell and taste of established whisky. Polyphenols become developed from substances in the wood of the cast including lignin and tannin. In whisky ellagic, gallic acids and lyoniresino are the most common polyphenols. They occupied 20% of the total free-radicals scavenging activity in whisky. [17]

Storage at Home

Contrary to wine, whisky does not mature after it has been bottled. If stored out of direct sunlight, a whisky's quality will not deteriorate or improve, and the whiskey will taste and smell the same. There is no expiration date regarding whisky, and it will not go bad even years after it has been opened. [2]

Flavour & Aroma

Before tasting the whisky, it is important to focus on the aroma because the nose can make codes for around 10,000 odors, whereas the tongue only has five taste buds. It is essential to gradually bring your nose closer to the glass until you get a sense of what the whisky smells like so the alcohol doesn't overwhelm the aromas. Most often a stronger smell often denotes a higher alcohol content and vice versa. Also, a stronger whisky may mask some of the taste that could be acquired by the palate and also the aromas in the nostrils, as the alcohol content inhibits the ability of the senses. Mouthfeel is a term used by many whisky critics to describe how the whisky feels in the mouth, by analyzing the weight and thickness in the presence of the oral cavity. The mouthfeel for whisky can range from thin and light, to thick and full.

Unlike wine, whisky maturation does not continue passed removal from the cask. However, there are still a few ways to alter the taste. For example, serving whisky on the rocks or chilling the whisky, can tamper with the flavour because the cold temperature shrinks the drinker's taste buds. Also, well-respected whisky connoisseur Michael Jackson, suggests adding water to whisky because it tempers the stinging sensation and releases nuanced aromas by diluting the alcohol content. With this said however, one must be careful when adding water to older whiskies because they are more delicate and sensitive to mixture. Adding too much water to an older whisky can result in the drink tasting flat.

World-renowned whisky experts Dave Bloom and Jim Beveridge developed a flavour map of single malt whiskies. [18]The whiskies are plotted on a map with four axes- delicate, smoky, light, and rich. Whiskies plotted at the "delicate" axis typically don't use peat in the malting process. "Peat is earth that consists of grasses, moss, tree roots, dead animals and soil that has become tightly compacted over thousands of years".[19] Whiskies near the smoky axis contain noticeable levels of peat, which is burned in the malting process. The light whiskies exhibit fresh flavors: green grass, soft fruits, and cereal. Finally, whiskies at the rich end of the axis contain characteristics often from from the nature of the wood used during maturation. Flavours range from vanilla that would originate from an American oak cask, to cigar box, chocolate, and dried fruit which would originate from European oak casks.

Appearance

The shade of a whisky beverage can range between transparent to deep brown, with colors from the yellow, red, and brown families. The color of whisky is due to the events that occur during the maturation process, in particular, the casks that are used for storing the whisky. Not only does the material influence the color, but also the previous usage of the casks can also affect the colour due to left over ingredients. Some alcohols are strong enough to overpower the influence of the oak and other materials included in the walls of the casks, which is beneficial because it keeps out the unwanted flavours. The oxidaton process plays a large role in influencing the final flavour of the whisky. Generally a deeper and darker coloured whisky is the result of a longer maturation time, meaning the whisky has spent a significant amount of time in contact with the oak casks. Most commonly, casks that have previously held sherry or bourbon are used for maturing the whisky. Also, the more often a cask is used it has a lesser influence on the contents, because the alcohol has had time to strip away the interior layers of the casks. For example, a cask that has been used multiple times will give way to a whisky that has a lighter color than that of a new cask.

Trends

According to the Association of Canadian Distillers,whisky sales in Canada have slightly increased by 0.9% following a three year decline in sales. However, domestic (Canadian) whiskies are declining -2.2%, whereas import whiskies such as Irish whisky, Bourbon, and Scotch have increased. Bourbon has increased the most with a 12.2% MAT (Moving Annual Total as of January 1, 2012).[20]

Summary and Reflection

From our research into the world of Scottish malted whisky, we have begun to understand the culture surrounding the appreciation of Scotch. The process of making whisky is traditional and artistic, involving quality ingredients, and certainly patience (a “fine” whisky might mature for over a decade, some more than sixty years!)

Making single malt Scotch is an involved and intricate procedure. Every step must be scientifically controlled and systematically followed in order to turn barley and water into the final whisky product. The barley grain must be manipulated by heat, humidity, and time in order for it to change its structure from complex proteins to sugars, which are easily utilized by the yeast during fermentation. The quality of the water used to create the fermentable substance wort is extremely important because it will determine the quality of the final product. Not just any old tap water is used. Clean, soft, slightly acidic water from a Scottish spring is needed to create a fine malt Scotch. The ingredients are extremely important in the production of Scotch whisky, the barely and water must be of the purest and highest quality. Scottish whisky companies certainly spare no expense when it comes to finding the most wholesome barely and water to make their whisky, perhaps that is the reason that Scotland is revered all over the world for its fine single malt whiskies.

The yeast is introduced to the barley wort, and begins to ferment the sugars of the grain into ethanol. During the log phase of fermentation, the yeast ferments the sugars so rapidly that metal blades must be used to minimize frothing. After fermentation, the ethanol is distilled off twice, in order to ensure that the purest product. During the second round of distillation, only the so-called middle-cut of liquid will continue on to the maturation phase. This cut of the whisky is of the right alcohol content and is assuredly the purest of the rest of the batch. The middle-cut is determined by temperature and water content readings, which are determined by government regulations.

Perhaps the most important step in determining the final flavour and quality of the whisky is the maturation phase. This is the time when the alcohol will absorb flavour and aroma from the oak casks in which it is stored for at least three years. The ethanol will evaporate through the wood casks, leaving the final whisky at a reasonable 40% alcohol content.

All of the measures taken to process the whisky culminate to the moment when the lucky consumer will enjoy the taste and aroma of the final product. Similar to wine tasting, there are whisky experts who use their experience with single malt Scotch to guide others in getting the most out of their whisky product. Different whiskies will have different flavours ranging from vanilla to dried fruit. Part of the appeal of whisky is its dark amber, yellow, or brown colour. Different colours will be achieved by using variation in cask types.

References

- ↑ Watson, Bruce. (2012). “A Boat, A Scot, and the Most Expensive Whisky in the World.”

- ↑ 2.0 2.1 2.2 Scotch Whiskey Association. Hewitt, Gavin Cheif Executive. March 2012. Frequently Asked Questions. http://www.scotch-whisky.org.uk/swa/93.html.

- ↑ Hough, J.S., D.F. Briggs and R. Stevens. (1971). Malting and brewing science. Chapman and Hall Ltd., London. p. 678.

- ↑ 4.00 4.01 4.02 4.03 4.04 4.05 4.06 4.07 4.08 4.09 4.10 Lyons, T.P., (2003). Production of Scotch and Irish whiskies: their history and evolution. Alltech Inc., Nicholasville, KY, USA

- ↑ 5.0 5.1 5.2 5.3 http://www.beer-brewing.com/beer-brewing/barley_malts/malting.htm

- ↑ Beek, S. V. and Priest, F. G. (2002). Evolution of the Lactic Acid Bacterial Community during Malt Whisky Fermentation: a Polyphasic Study.,Appl. Environ. Microbiol. 68(1):297

- ↑ 7.0 7.1 7.2 Aylott, R.I., Machenzie, W.M., (2010). Analytical Strategies to Confirm the Generic Authenticity of Scotch Whisky. Journal of Institute of Brewing, 116(3), 215-229.

- ↑ 8.0 8.1 http://www.whiskyforeveryone.com/index.html

- ↑ Antonio J. A. Meirelles, Eduardo A. C. Batista, Helena F. A. Scanavini, Fábio R. M. Batista, Roberta Ceriani, and Luiz F. L. Luz, Jr. (2009). Extracting Bioactive Compounds for Food Products Theory and Application. CRC Press 2008.

- ↑ McCabe, John T. Method for Aging Whiskey. (1963). United States Patent Office.

- ↑ Armand R. Boucher, (1974). Whiskey Barrel. 1st ed. United States: Google.

- ↑ Whiskeywise (2006-2012). Whiskey barrels - Oak gives the real taste to the Whiskey. [ONLINE] Available at: http://www.whiskeywise.com/whiskey-barrels.html. [Last Accessed 15/03/2012].

- ↑ Armand R. Boucher, (1974). Whiskey Barrel. 1st ed. United States: Google.

- ↑ Whiskeywise (2006-2012). Whiskey barrels - Oak gives the real taste to the Whiskey. [ONLINE] Available at: http://www.whiskeywise.com/whiskey-barrels.html. [Last Accessed 15/03/2012].

- ↑ US Government (2012). Alcohol, Tobacco, and Firearms. [ONLINE] Available at: http://ecfr.gpoaccess.gov/cgi/t/text/text-idx?c=ecfr&sid=21224b7c634d83e0fa329bfd18bb85dc&rgn=div8&view=text&node=27:1.0.1.1.3.3.25.2&idno=27. [Last Accessed 15/03/2012].

- ↑ Department of Justice Canada (2012). Canadian Whiskey, Canadian Rye Whiskey, or Rye Whiskey. [ONLINE] Available at: http://laws-lois.justice.gc.ca/eng/regulations/C.R.C.,_c._870/section-B.02.020.html. [Last Accessed 15/03/2012].

- ↑ Koga, K., Taguchi, A., Koshimizu, S., Suwa, Y., Yamada, Y., Shi, N., (2007) Reactive Oxygen Scavenging Activity of Matured Whiskey and Its Active Polyphenols. Journal of Food Science, 72, 212-217.

- ↑ http://www.malts.com/index.php/en_can/Choosing-Whisky/A-World-of-Flavour/The-Single-Malt-Whisky-Flavour-Map

- ↑ http://www.whiskyforeveryone.com/whisky_basics/influence_of_peat.html

- ↑ Association of Canadian Distillers. Accessed March 21, 2012.