Course:ECON371/UBCO2010WT1/GROUP2/Article4

Back to

Group 2: The Environmental Impacts of Natural Gas Extraction

Article 4: Frack Fluid Spill in Dimock Contaminates Stream, Killing Fish [1]

Summary

In September 2009, the town of Dimock, Pennsylvania, experienced water pollution due to a spill of hazardous chemicals used by Cabot Oil & Gas in the hydraulic fracturing process. A local creek has been affected. The Pennsylvania Department of Environmental Protection (DEP) reported fish killed or swimming erratically as a result of exposure to these chemicals. The chemicals, manufactured by Halliburton, may affect the nervous system and are potential carcinogens.

Cabot's drilling seems to be linked to many other environmental problems in the area of Dimock. In winter 2008, drinking water of several Dimock homes contained elevated levels of metals and methane gas. This pollution seems to have leaked underground from Cabot wells. In spring 2009, Cabot was fined for several other spills. However, the drilling fluid spill of September 2009 appears to be the most serious as the released chemicals pose a serious danger to human health and have spread into the surface water. Supply pipe failures seem to be the cause of this spill.

In a state where public awareness of the dangers of hydraulic fracturing has led to increased governmental discussions and the issue of accountability, this incident is one of many that pose the potential for greater affirmative action on the negative effects from natural gas extraction.

Analysis

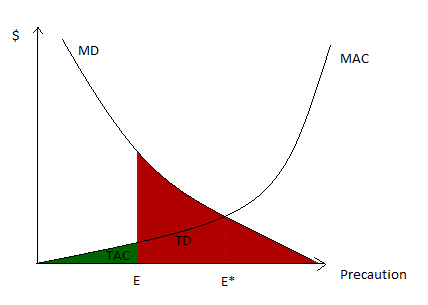

The fracturing fluid

spill in Dimock is an example of an episodic emission. Figure 1 on the right shows the possible MAC and MD curves for this emission. Since continuous emissions cannot be monitored in this one-time event, the horizontal axis represents precaution rather than emission. When the company takes zero precaution, its abatement costs are zero. However, since the chemicals used in fracturing have a large impact on human health, at a low level of precaution, the potential for damage is very large. To reduce this potential, the company would inspect piping regularly to prevent any cracks or leaks. The inspection and replacement of damaged pipes would increase the company's abatement costs, but it would decrease the potential for a spill. It is likely that the environment would be able to assimilate some low level of emission, thus the marginal damage would be greatly decreased. To reduce the potential damage to near-zero levels, the company would need to take a lot of precautions. At the highest level of precaution, the company would close down. If there is no fracturing, the potential for damage from fracturing fluids is zero. However, this would represent a very large marginal abatement cost to the firm. At the present, it seems that Cabot's level of precaution E is below the efficient level E*, which results in many spills in the area. At this level, the total damage TD far exceeds the total abatement costs TAC. As such, government intervention is required to help move the industry towards the efficient level of precaution which will minimize the difference between TAC and TD.

Government Policy:

In terms of a governmental policy, it will likely arise from the scrutiny and increased demands from the public as these incidents increase in number. However, the debate between the government and the companies alleged of doing the damages raises the issue of liability laws and burden of proof. Cabot Oil and Gas, for example, released a statement on their website (http://phx.corporate-ir.net/staging/phoenix.zhtml?c=116492&p=irol-newsArticleright&ID=1475122&highlight=) shifting blame to the “automobile and truck repair garage” in the vicinity in which the chemicals of the incident all “are commonly used in automotive fluids.” Proof issues are also brought up with Cabot’s own research claiming that the chemicals were present before their production began in 2008. Since causal linkages are not yet clear and there are problems with meeting the burden of proof, using liability laws to internalize externalities will not work in this case until further research of the area is conducted to determine the true source of pollution.

The government should move towards a more centralized technique, for example technology standards. Cabot would be required to use certain pipe design and chemicals as set by the government. Problems arise with this technique if there is uncertainty about the location of the MAC and MD curves. If the government doesn't know the true MAC and MD curves, it may set a standard at a level that is not efficient, thus causing net social loss. It is assumed that Cabot meets the standard to avoid paying fines for violation. Once the standard is met, the government gets no information about Cabot's MAC curve and thus cannot adjust the standard to move toward efficiency. There is also no incentive for Cabot to invest in R&D to reduce the potential for emissions to the efficient level. Thus a high level of information is required to set the correct standard. However, the incentive is present for Cabot to misrepresent its MAC. If the government believes Cabot's MAC curve to be higher than it really is, the standard will be less stringent. Thus there will be a greater risk of pollution.

However, the lack of transparency by the companies about the substances being injected into the shale for natural gas extractions might clear up with more government intervention and regulation, such as the Department of Environmental Protection in Pennsylvania. In so far as information is kept secret, the social efficiency will not be achieved and society will be at a loss.

Prof's Comments

Nice, clear explanation of how to interpret the choice of precaution, and the issues involved with liability.