Course:ECON371/UBCO2009WT1/GROUP5/Article4

Turning toxic coal ash into bridges, buildings

Article

http://edition.cnn.com/2009/TECH/03/20/recycled.coal.uses/index.html#cnnSTCText

Summary

This article states that a billion gallons of ash sludge spilled from a holding pond and fouled 300 acres and two rivers near the Tennessee on December 22, 2008. Later, the Environmental Protection Agency promotes their beneficial reuse in order to reduce the need to store coal waste produces. The American Coal Ash Association shows that about 43 percent of the 131 million tons of coal combustion products, which including fly ash, bottom ash and boiler slag, generated in 2007 found beneficial uses. However, some environmentalists are skeptical about that claim. There, the author described the useful of coal combustion products using fly ash and gypsum as examples. According to the coal ash group, there are more than 80percent of coal-plant boiler slag was utilized, mostly for sandblasting or as the grit on roofing shingles in 2007. And about 44 percent of fly ash found uses, mostly as a substitute for some of the Portland cement in concrete, whose production release large amounts of the greenhouse gas carbon dioxide. Colin Lobo said, fly ash make concrete stronger and less porous, as well as generally less expensive. Freedom tower, the Ronald Reagan Government Office Building and the complex being built on the former site of the World Trade Center in New York are the prominent projects where fly ash has replaced significant amounts of Portland cement. However, the volume of coal ash people creating is far larger than people could ever put into asphalt and drywall concrete blocks, the volume is staggering, said Mary Anne Hitt. Although it caused a massive spill, coal ash was found many uses that benefit industry and even the environment.

Analysis

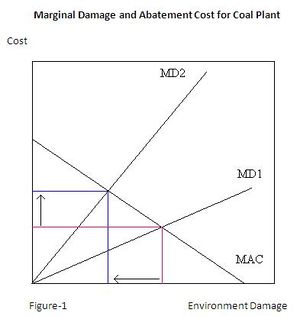

Abatement Cost for Coal Combustion Plant

Marginal Damage (MD1) curve represents marginal damage before the spill of ash sludge from a holding pond. Marginal Damage (MD2) shows the damage of the pollution towards the environment after the incidence. Damage toward environment in Tennessee was significant since a billion gallons of ash sludge fouled 300 acres and two rivers. Since TVA (Tennessee Valley Authority’s Kingston Fossil Plant) has to clean up the pollution material, the cost of abatement increases from the red line equilibrium to the blue line equilibrium with improving the quality of the environment.

Marginal Social Cost and its Externality

Marginal External Cost (MEC) curve shows the cost which the environment damage from the incidence imposes on residences. For this incidence, residences in the polluted area incur the external cost. Because of the incidence, the water near the Plant is contaminated. Thereby, it may require residences the installment of the water purifier in order to remove the unhealthy materials.

As a result of the external cost to the neighbor of the plant, social cost increases. And social benefit will decrease. Figure-3 illustrates this transition. MPC is the curve of Marginal Private Cost for Coal Combustion Plant (Kingston Fossil Plant). Marginal Social Cost (MSC) is the curve that represents the combined cost of both the private cost (The Cost for Kingston Fossil Plant) and the external cost (The Cost for residences in abating environment damage).

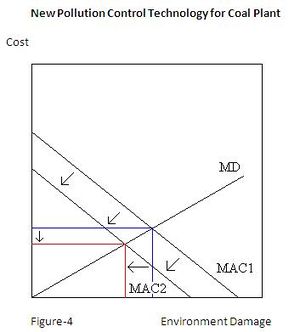

Coal Waste to Good Use

The Environmental Protection Agency (EPA) promotes to put coal waste to good use. As a result, TVA will incorporate a new pollution control technology into the combustion plant. The new technology enables the plant to make the good use of fly ash as a substitute for some of the Portland cement in concrete. MAC 1 in figure-4 is the Marginal Abatement Cost before the use of the new technology. After beginning to use the new technology, MAC 2 shifts down due to an efficient technology for the coal burning pollutions. The red line equilibrium indicates an improved environment quality and reduced cost. After adopting the new technology, the environment becomes clearer. And the plant supplies the recycled byproducts of the coal burning for the Portland cement in concrete.

Prof's Comments

Being able to turn a waste product from coal burning into something of value is probably best thought of as an inward rotation of the MAC curve. A reduction of emissions by one unit is less costly because there is some revenue generated from dealing with the waste. As a result, the new efficient intersection involves lower emissions. An alternative is to think of it as an inward shift. If some portion of the emissions are profitable to recover and sell, then the polluter will do so voluntarily, and reduce their emissions level without any incentive to do so.