Extreme heat exposure in furnaces

Recognition

Heat stress is defined as the overall heat load to experienced by a worker through combined exposure to metabolic heat, air temperature, humidity, air movement, radiant heat, and clothing. Thus, we must consider several sources when attempting to recognize heat stress in an occupational context. For example, in furnaces and aluminum smelters, hot or molten material is the main source of heat. In contrast, road building, repair and construction receives major heat exposure through sunshine. In kitchens, high humidity may be a causal factor in increasing heat stress. Increased heat burden may cause people to become irritated, loss concentration and lose ability to perform skilled work. Signs of heat exhaustion include dizziness, nausea, fatigue, thirst, headaches and high body temperatures. The most deadliest illness associated with heat exposure is heat stroke. It can result in complete loss of conscious and death due to the inability of the body to regulate internal temperature and dissipate heat. [1]

Evaluation

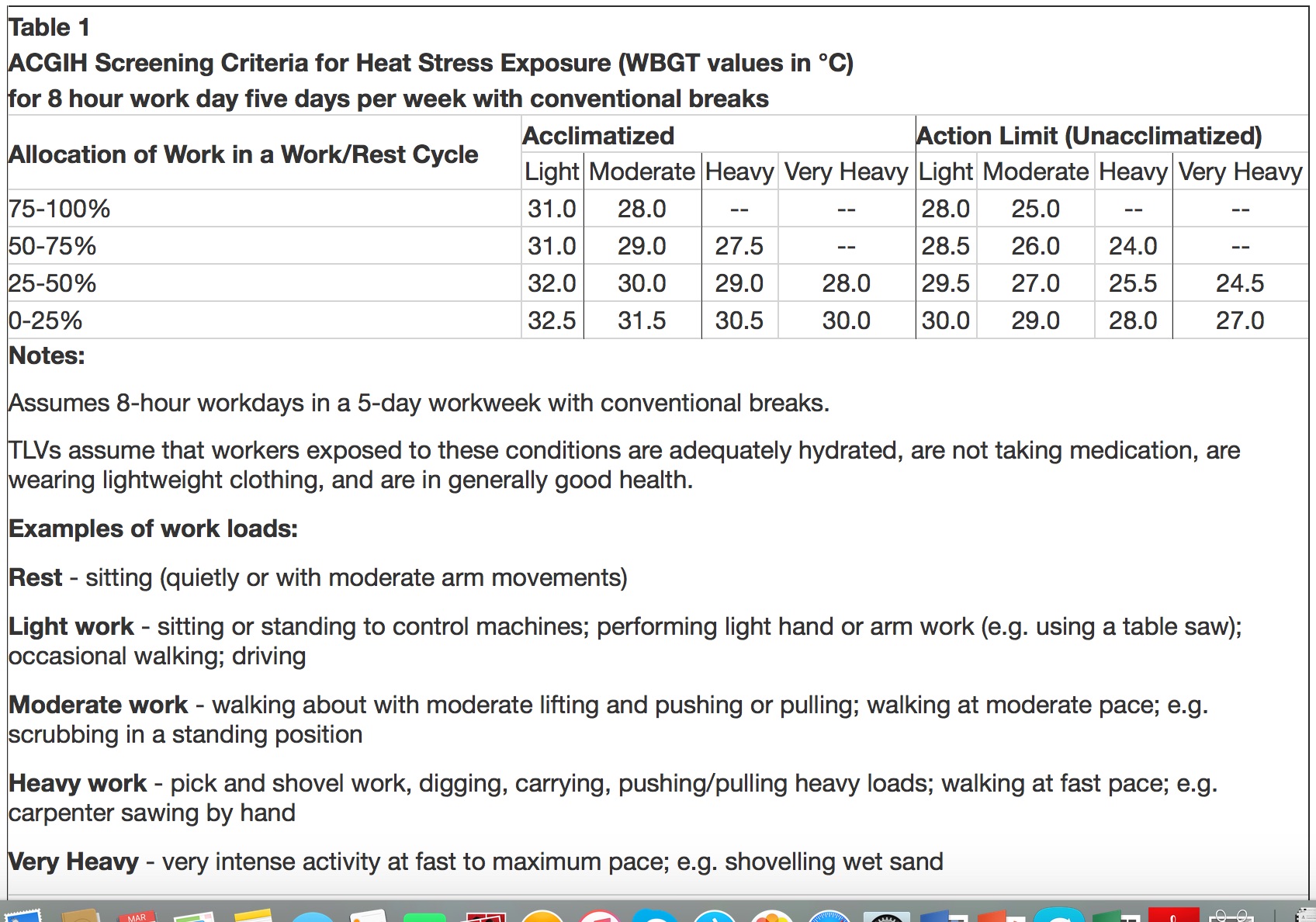

A comfortable environment for most humans comprises a temperature anywhere from 20 to 27 degrees Celsius while the range for humidity is around 35% to 60%. Higher humidities and environmental temperatures of over 30 degrees Celsius may start impairing body systems. Internal temperatures of the human body is maintained around 37 degrees Celsius and fluctuates by less than 1 degree Celsius throughout the day. However, an internal temperature reading of more than 38 degrees Celsius may represent the beginnings of heat burden on the human body. Below is a table of screening criteria for heat stress exposure to workers using WBGT values (calculated using speed of air movement, air temperature, radiant heat from hot objects, sunshine, and body cooling due to sweating). [1]

Controls

There are a number of recommended controls published by the Canadian Centre for Occupational Health and Safety for reducing heat stress in the workplace. [1]

Administrative controls

While heat stress cannot be eliminated in certain contexts, such as high-heat furnaces, administrative practices can reduce the heat burden on workers. Employers can ensure that workers have adequate breaks from hot, internal environments at appropriate times throughout the day. Employees should be encouraged to discontinue work after a certain criterion (such as WBGT) is reached to prevent heat illness. Allowing workers to set their own pace of work and providing sufficient drinking water stations can help reduce body heat burden.

Education

Employees can be trained and educated in recognizing signs of heat illness and exhaustion.

Engineering controls

The Canadian Centre for Occupational Health and Safety lists engineering measures as one of the most effective controls to prevent heat stress. Adding automation and mechanization of tasks can reduce heavy physical work and body heat accumulation. Covering hot surfaces with sheets of paint of aluminum can reduce radiant heat. Insulating heated surfaces can reduce heat exchange between the environment and the heated surface. Stainless steel or aluminum shields can reflect heat back to the source, while water-cooled jackets can absorb radiant heat. Air conditioning and ventilation, and even cooled booths can drastically reduce environment heat and humidity

Personal Protective Equipment

PPE such as specifically designed heat-absorbing clothing or light clothing can improve body cooling by sweat evaporation and reducing radiant heat absorption. Workers have reported long underwear to moderate changes in extreme temperature conditions, such as moving from very cold to very hot and dry environments. Specially fitted eye protection can reduce radiation from hot molten metals and furnaces.

References

- ↑ 1.0 1.1 1.2 Government of Canada, Canadian Centre for Occupational Health and Safety. (2017). Hot Environments - Health Effects and First Aid : OSH Answers. Retrieved from <https://www.ccohs.ca/oshanswers/phys_agents/heat_health.html>.