Course:SPPH381B/Essay 3/E-Waste - Zahra

Introduction

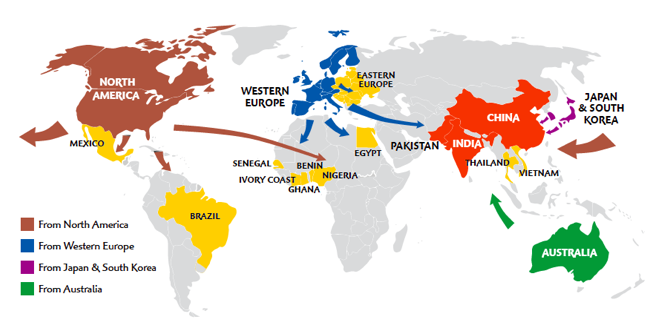

E-waste or waste electrical and electronic equipment (WEEE) is currently the largest growing waste stream [1]. TVs, telephones, computers, refrigerators, DVD players, air conditioners and much more fall under e-waste classification [2] . Eight percent of the e-waste in developed countries that is sent for recycling ends up being shipped to developing countries such as China, India, Ghana and Nigeria [1]. The shipments are often done illegally and the actual recycling process is performed by informal workers who are subject to multiple vulnerabilities [1]. While an international treaty adopted in 1992, the Basel Convention, aimed to reduce the amount of transnational hazardous waste [3], it has been relatively ineffective, as traffickers disguise shipments of e-waste or state that they are intended for re-use [2]. The issue of e-waste is the dark side of technological innovation. One of the challenges of e-waste management is that most electronic products were not prospectively designed with regards to how they would be recycled, disassembled and properly disposed of. Currently, most e-waste is disposed of within the general waste stream [1].

Figure 1.1 Flow of E-Waste[1][2]

Hazards

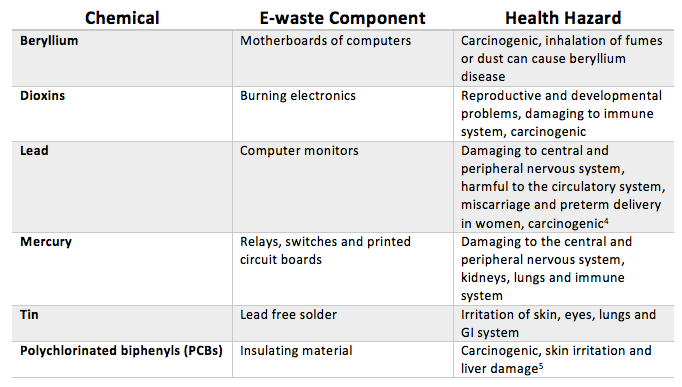

In many places where e-waste is being recycled, there is a lack of technology and infrastructure to complete the process in a safe manner. Workers defer to crude methods which can be very harmful to their wellbeing. Objects are physically dismantled by hand, acid baths used to recover gold and cables are burned to recover copper [4]. Worker’s health can be compromised through exposure to hazardous materials such as lead, mercury, persistent organic pollutants and flame retardants, which are within the e-waste itself [1]. Workers can also be exposed to harmful substances that are added during recovery processes, such as cyanide. Lastly, substances such as dioxins which are formed during e-waste recycling processes, pose an additional occupational health risk [1]. Figure 1.2 presents some of the health effects of substances from the e-waste recycling process.

Figure 1.2 E-Waste Hazards[5][6][1]

Controls

As mentioned previously, the developing countries deal with a disproportionate amount of e-waste as many developed nations export their waste to developing nations [1]. The Basal Convention on the Control of Transboundary Movements of Hazardous Wastes and their Disposal is an example of an international initiative to combat export of e-waste [7]. This initiative could be classified under the elimination category of the occupational control hierarchy. However, additional controls are necessary for two very important reasons. First of all, domestic generation of e-waste is a growing problem in all countries. Additionally, current illegal trades of e-waste provide livelihoods for many individuals who are part of the informal e-waste recycling industry [1].

Prolonging the life span of electronics or shifting the culture towards reusing or repairing electronics, are examples of controls to reduce the amount of e-waste. Interestingly enough the total use time of some electronics before they are discarded has been decreasing. The average lifespan of computers was six years in 1997 and came down to two years in 2003 [8]. Substitution of non-toxic chemicals used in the production of electronics seems presently unattainable and the toxicity of many elements used is also unknown [1]. Additionally, even when electronics do not contain toxic materials, crude recycling techniques such as burning still have negative health effects [1]. Work areas should be enclosed with proper exhaust ventilation [1]. If this is not possible, respirators should be worn. Impermeable clothing and eye, face and hand protection should be provided to workers. However, it is not enough to just provide the materials, PPE should be provided as part of a program educating workers on the importance of PPE and how to wear it correctly. The implementation of these controls in informal industries is difficult due to minimal resources and low education levels. A multi-sectoral approach which works to alleviate poverty and improve working conditions is needed.

One of the technological trends has been the movement towards the use of flat panel displays and away from cathode ray tube screens (CRTs) [9]. As a result, many end-of-life CRTs must be dealt with. The process of recycling CRTs is complex because they each contain an average of 1-1.5 kg of lead and there is no longer a demand for re-purposing old CRTs into new ones [9]. Additionally, extracting the lead from CRTs is costly [9]. The rate of turnover for electronic objects is rapid and even flat screens and other LCD objects are increasingly appearing in e-waste [10]. Although innovative and user-friendly, LCD technology challenges waste management due to the high level of mercury within the black-light [10].. E-waste management is so complex because it has to adapt to continuous change in technology. This is why a movement towards green design and extended producer responsibility is important. Green design pushes for easier disassembly of objects, minimal toxic substances and being conducive to repairs and upgrades [1]. With extended producer responsibility, manufacturers bear the cost of end-of-life and therefore may be more inclined to develop objects in line with green design principles.

References

- ↑ 1.00 1.01 1.02 1.03 1.04 1.05 1.06 1.07 1.08 1.09 1.10 1.11 1.12 1.13 Lundgren, K. (2012). The global impact of e-waste: Addressing the challenge. Retrieved from http://ilo.org/wcmsp5/groups/public/---ed_dialogue/---sector/documents/publication/wcms_196105.pdf

- ↑ 2.0 2.1 2.2 Lewis, A. (2010, August 4). Europe exporting electronic waste despite ban. BBC. Retrieved from http://www.bbc.com

- ↑ IISD. (2010). A Brief Introduction to the Basel Convention. Retrieved from http://enb.iisd.org/process/chemical_management-baselintro.html

- ↑ Annamalai, J. (2015). Occupational health hazards related to informal recycling of E-waste in India: An overview. Indian journal of occupational and environmental medicine, 19(1), 61. Retrieved from https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4446940/

- ↑ CAREX Canada. (2016). Lead. Retrieved from http://www.carexcanada.ca/en/lead/

- ↑ CARES Canada. (2015). Polychlorinated Biphenyls. Retrieved from http://www.carexcanada.ca/en/polychlorinated_biphenyls/

- ↑ Widmer, R., Oswald-Krapf, H., Sinha-Khetriwal, D., Schnellmann, M., & Böni, H. (2005). Global perspectives on e-waste. Environmental impact assessment review, 25(5), 436-458. Retrieved from http://www.sciencedirect.com/science/article/pii/S0195925505000466

- ↑ Mvo Platform & GoodElectronics. (2009). Reset: Corporate social responsibility in the global electronics supply chain. Retrieved from http://electronicswatch.org/reset-corporate-social-responsibility-in-the-global-electronics-sector-_6126.pdf

- ↑ 9.0 9.1 9.2 Restrepo, E., Widner, R. & Schluep, M. (2016). Leaded Glass from Cathode Ray Tubes: A Critical Review of Recycling and Disposal Options. Retrieved from UN Step Initiative website: http://www.step-initiative.org/

- ↑ 10.0 10.1 Felix, J., Tunell, H., Letcher, B., Mangold, S., Yang, J., Retegan, T., ... & Ljungkvist, H. (2012, September). Increasing the sustainability of LCD recycling. In Electronics Goes Green 2012+(EGG), 2012 (pp. 1-6). IEEE. Retrieved from https://www.researchgate.net/profile/Johan_Felix/publication/261242975_Increasing_the_sustainability_of_LCD_recycling/links/55d6fc5208ae9d65948c1d4f.pdf

.